Rose soy sauce and preparation method thereof

A technology of soy sauce and rose, applied in food ingredients as odor modifiers, food science and other directions, can solve the problems of soy sauce saltiness, acidity discomfort, remaining rose slag, and can only be used as fertilizer, etc., to improve competitiveness, The effect of less coloring and rich aroma of soy sauce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

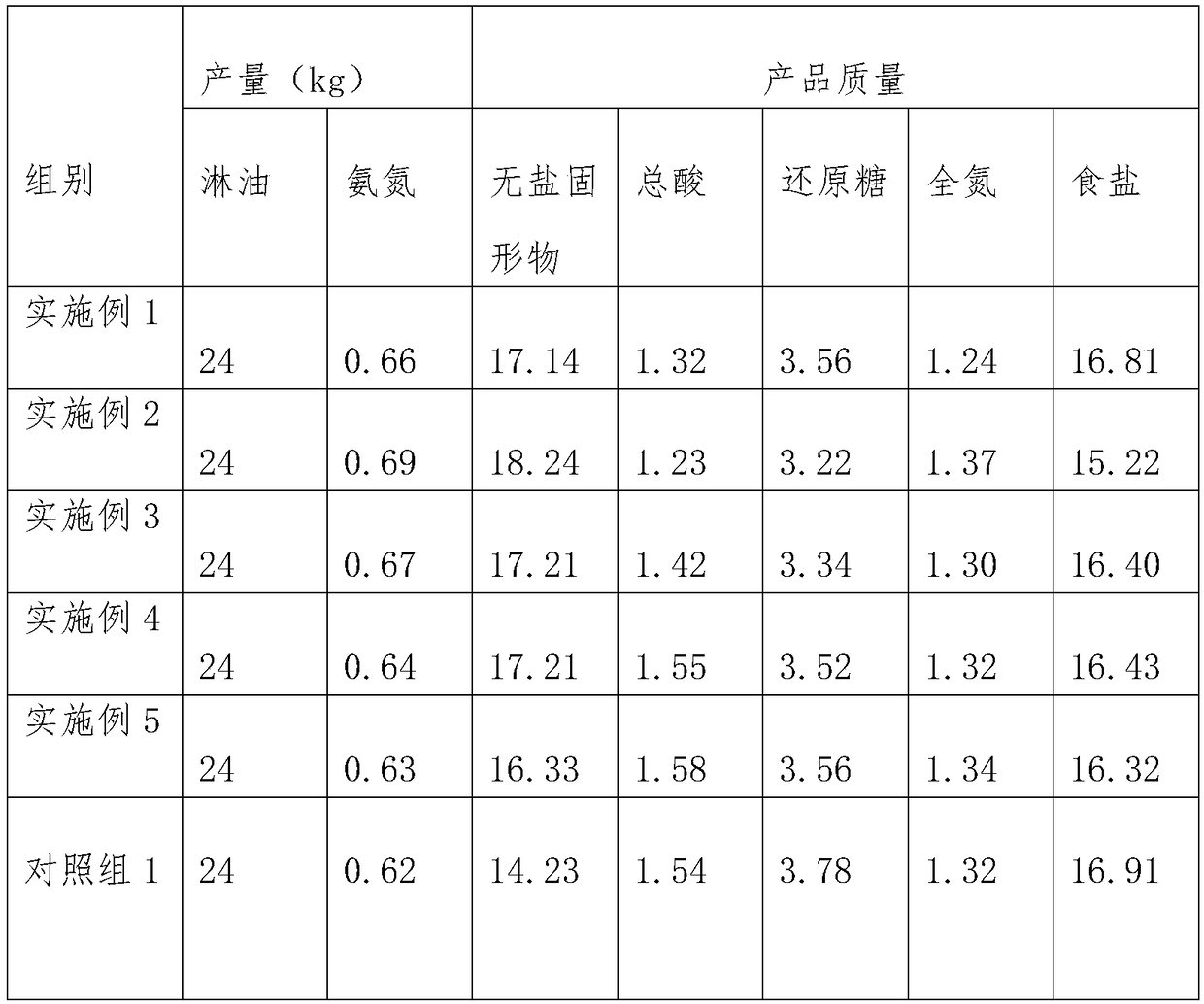

Examples

Embodiment 1

[0016] Raw materials: the soy sauce is composed according to the following parts by weight: 50 kg of defatted soybeans, 0.4 kg of edible salt, 4 kg of wheat, 5 kg of sodium glutamate, 6 kg of rose residue, 6 kg of alcohol, and 33 kg of water;

[0017] Processing method: (1), raw material pretreatment and mixing: firstly cook the soaked defatted soybeans, rose pomace, and wheat, then pass through a 10-20 mesh sieve, and mix evenly to obtain the mixed material; (2), moisturizer: Add edible salt to the material, and spray the alcohol solution with a concentration of 1.7%, moisten the material for 25-30min, and obtain the mixture; (3), inoculation: when the mixture is cooled to 25-33°C, inoculate the mixture with 0.3-0.5% rice koji enzyme, culture mixture, koji is formed after 1-2d, and the koji is turned once in half a day to obtain moromi; (4), early stage of fermentation: 60-80d before fermentation, add flour koji and salt to the moromi, and ferment After 160 days, which is the...

Embodiment 2

[0019] Raw materials: the soy sauce is composed according to the following parts by weight: 70 kg of defatted soybeans, 4 kg of edible salt, 12 kg of wheat, 12 kg of sodium glutamate, 15 kg of rose residue, 13 kg of alcohol, and 67 kg of water;

[0020] Processing method: (1), raw material pretreatment and mixing: firstly cook the soaked defatted soybeans, rose pomace, and wheat, then pass through a 10-20 mesh sieve, and mix evenly to obtain the mixed material; (2), moisturizer: Add edible salt to the material, and spray the concentration of 2.1% alcohol solution, moisten the material for 25-30min, and obtain the mixture; (3), inoculation: when the mixture is cooled to 25-33°C, inoculate 0.3-0.5% of the mixture Rice koji enzyme, culture mixture, koji is formed after 1-2 days, and the koji is turned once in half a day to obtain moromi; (4), early stage of fermentation: 60-80 days before fermentation, add flour koji and salt to the moromi, and ferment for 160 days Afterwards, th...

Embodiment 3

[0022] Raw materials: 130kg defatted soybeans, 6kg edible salt, 27kg wheat, 16kg sodium glutamate, 25kg rose residue, 16kg alcohol, 120kg water;

[0023] Processing method: (1), raw material pretreatment and mixing: firstly cook the soaked defatted soybeans, rose pomace, and wheat, then pass through a 10-20 mesh sieve, and mix evenly to obtain the mixed material; (2), moisturizer: Add edible salt water to the material, and spray the concentration of 2.4% alcohol solution, moisten the material for 25-30min, and obtain the mixture; (3), inoculation: when the mixture is cooled to 25-33°C, inoculate 0.3-0.5% of the mixture Rice koji enzyme, culture mixture, koji is formed after 1-2 days, and the koji is turned once in half a day to obtain moromi; (4), early stage of fermentation: 60-80 days before fermentation, add flour koji and salt to the moromi, and ferment for 160 days Afterwards, that is, the late stage of fermentation, spray the alcohol solution with a concentration of 3.5%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com