Laser processing method for air film holes of high-pressure turbine guiding blade

A laser processing method and turbine guide vane technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of damage to the inner cavity and poor consistency of parts, so as to improve the surface integrity and ensure the position The effect of reducing the error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

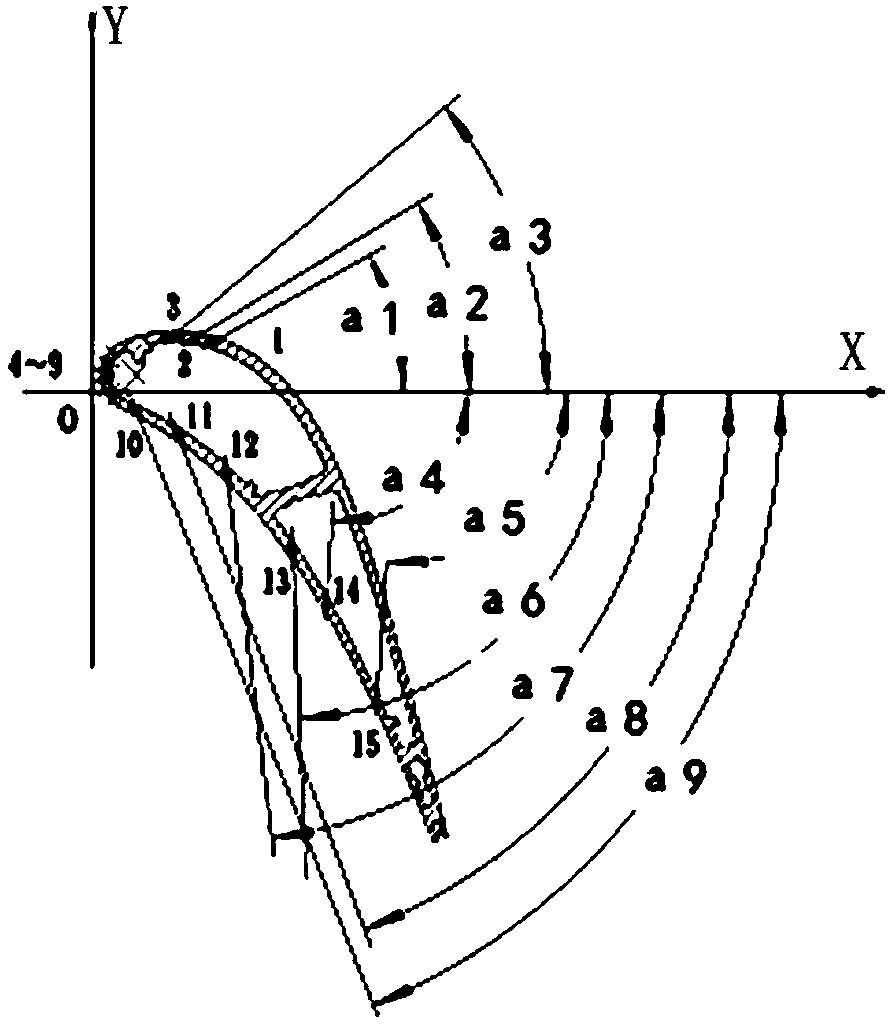

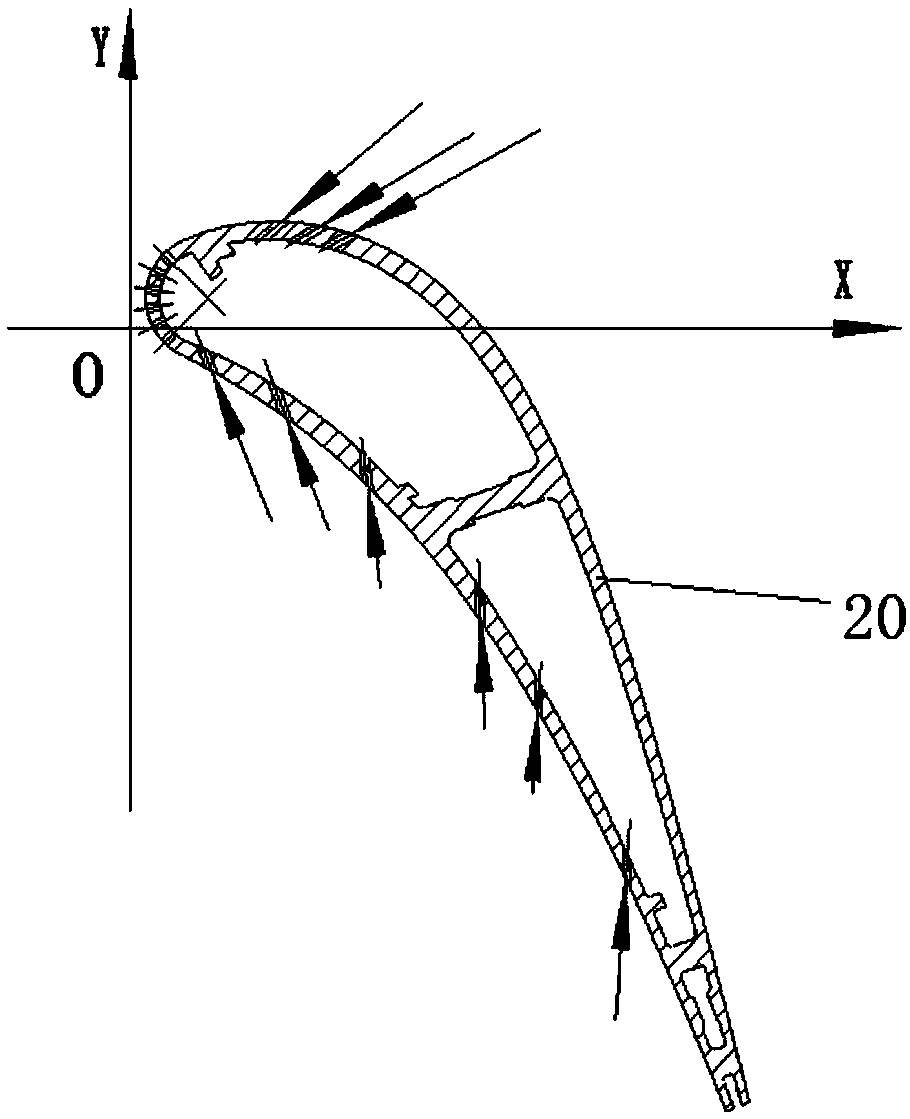

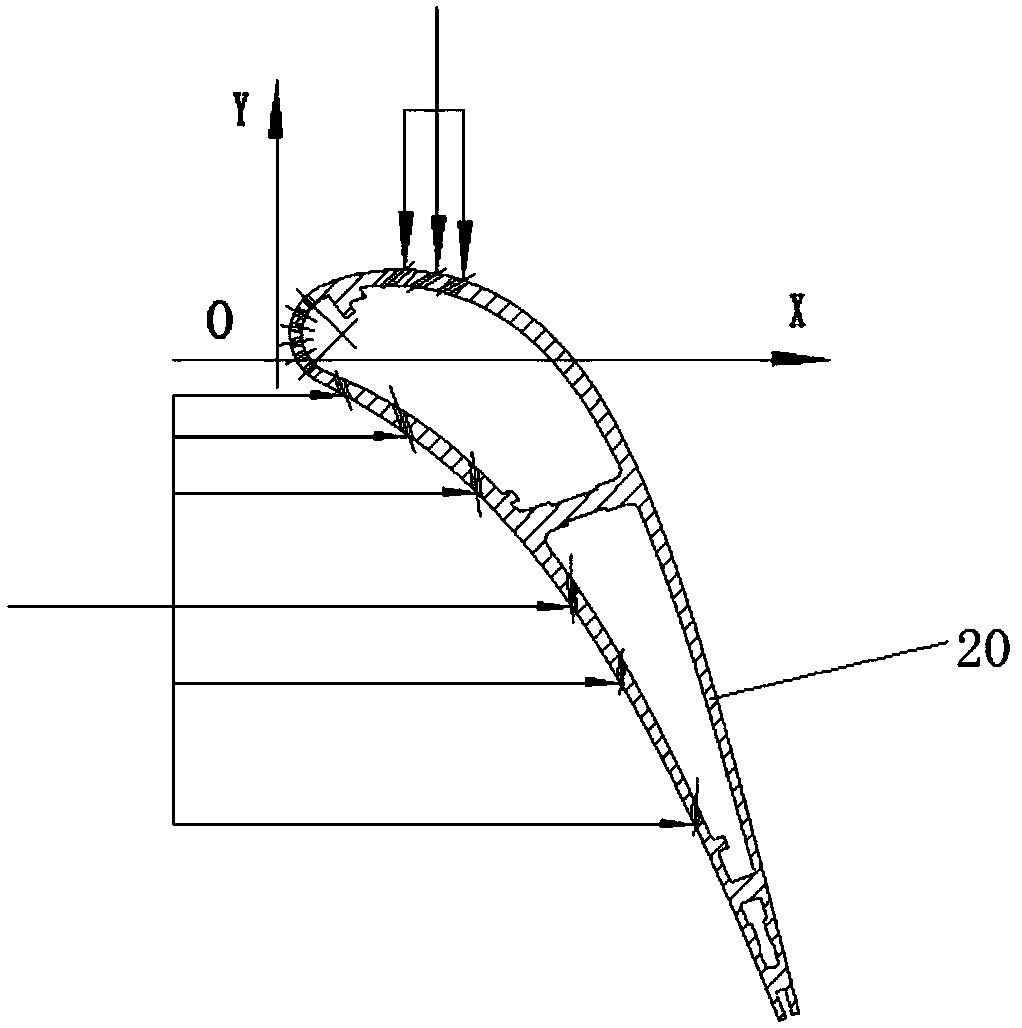

[0031] Analysis of the influence of the leaf profile on the air film hole position: as Figure 4 As shown, Ⅰ-Ⅰ, Ⅱ-Ⅱ, Ⅲ-Ⅲ represent the theoretical profile position, profile thickening position and profile thinning position of the turbine blade respectively. The laser beams J, K, L are parallel light. When the laser beam J irradiates the turbine blade profiles Ⅰ-Ⅰ, Ⅱ-Ⅱ, Ⅲ-Ⅲ, they will intersect at points O, O 3 , O 4 . Relative to the theoretical intersection point O, the intersection point O 3 and O 4 The position tolerance between the theoretical intersection point O is the radius R of the circle. It is manifested on the part, that is, when the profile of the turbine blade is thickened to the profile II-II, the intersection point of the air film hole and the profile surface of the part moves from the theoretical point O to the intersec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com