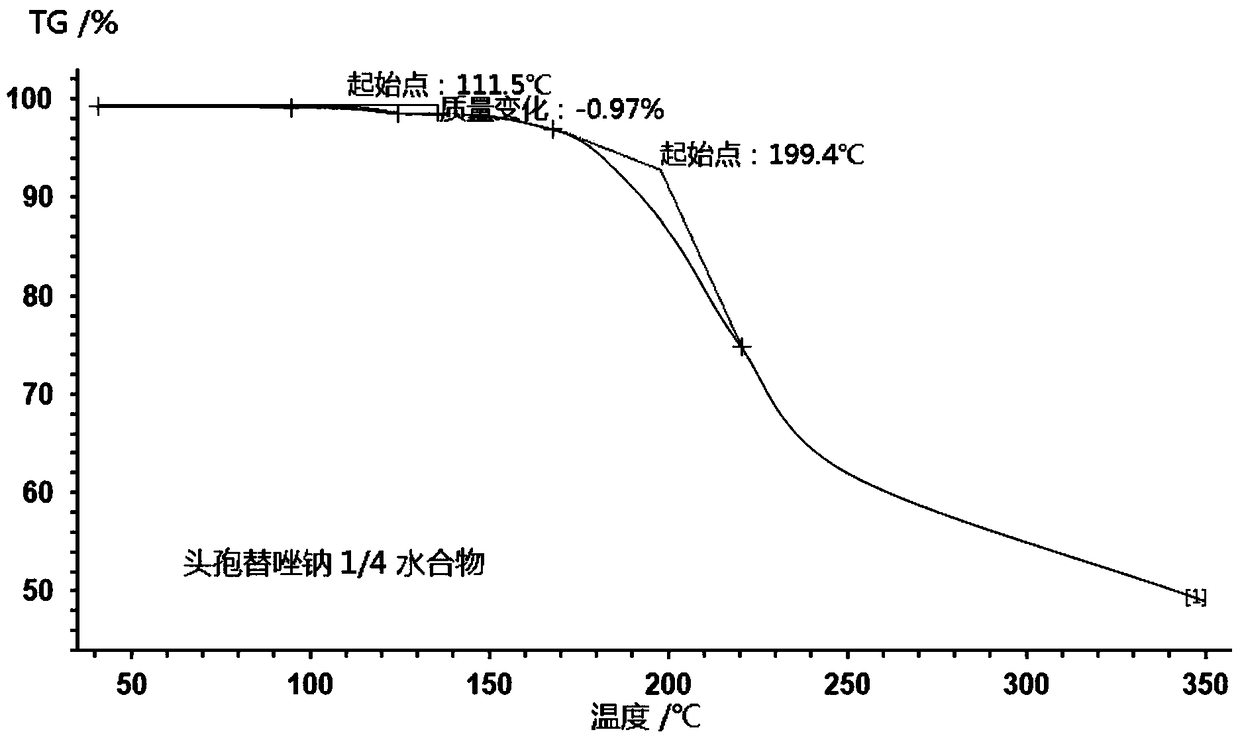

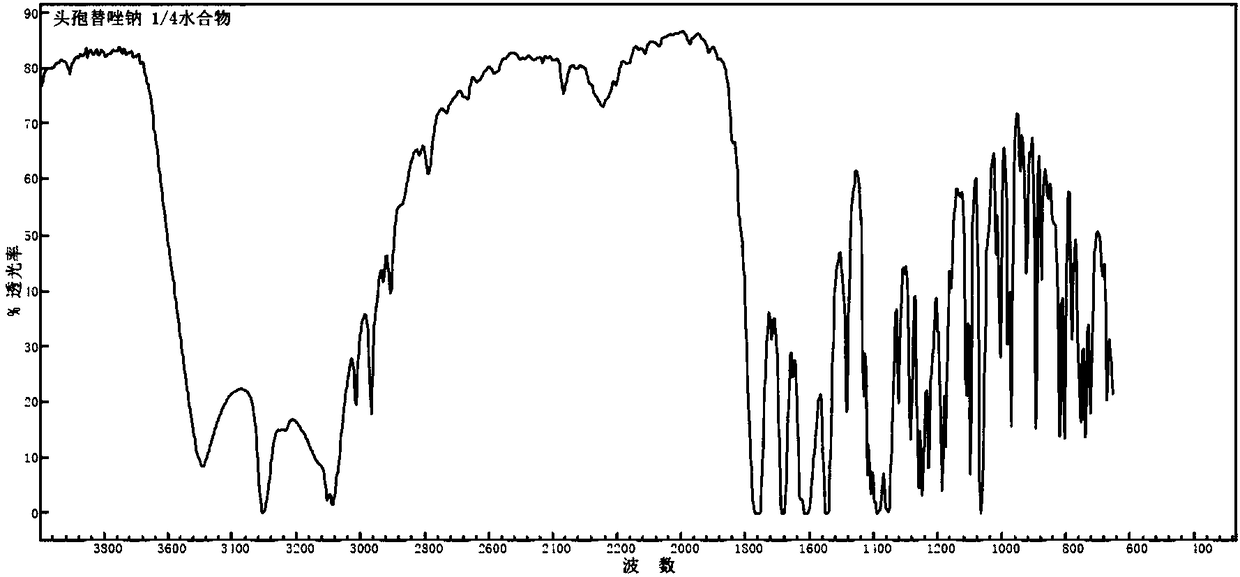

1/4 water ceftezole sodium compound

A technology of ceftezole sodium and its compound, which is applied in the field of 1/4 water ceftezole sodium compound and its preparation method, and can solve the problems of unsuitable storage, high environmental humidity requirements, poor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: Preparation of 1 / 4 water ceftezole sodium compound

[0025] At room temperature, dissolve 75.02g of sodium citrate in a mixture of 400ml of acetonitrile and 200ml of water, then add 100.05g of ceftezole and stir to dissolve, adjust the pH value to 4.0 with citric acid, add 6.12g of activated carbon, stir and adsorb for 30 minutes , decarbonized by suction filtration; washed the filter cake with 50ml of acetonitrile; lowered the temperature of the filtrate to 10°C, slowly added dichloromethane dropwise for 2h under stirring, filtered under reduced pressure, washed the filter cake with 50ml of dichloromethane, and dried under reduced pressure at 45°C After 4 hours, 83.26 g of ceftezole sodium compound in 1 / 4 water was obtained.

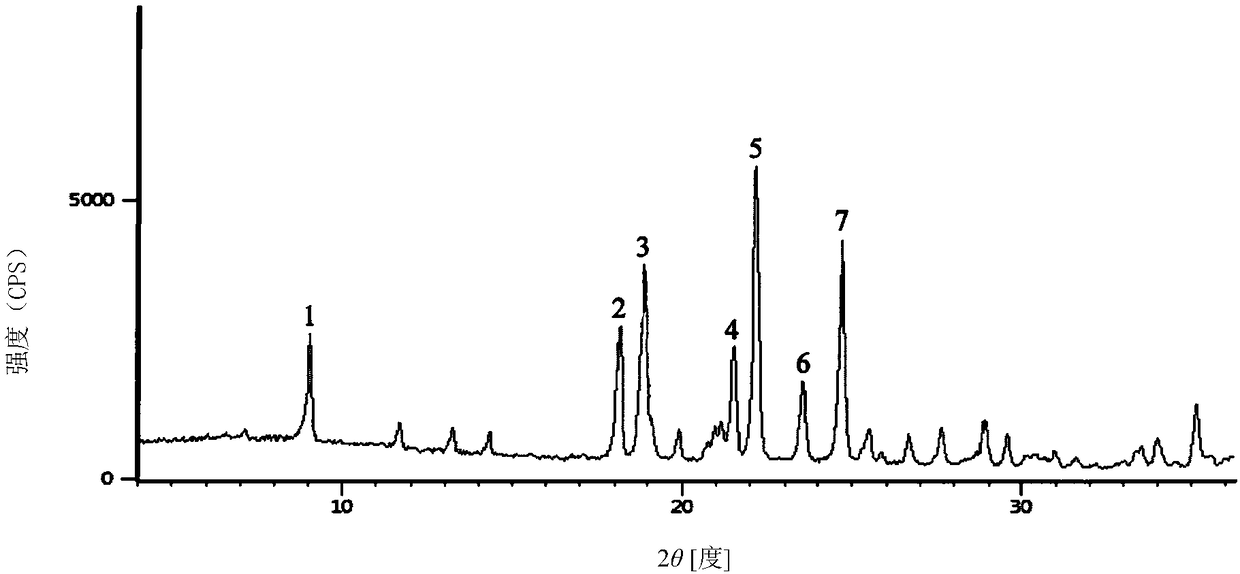

[0026] The powder X-ray diffraction pattern has characteristic diffraction peaks at the diffraction angles 2θ of 9.05°, 18.18°, 18.92°, 21.53°, 22.17°, 23.55°, and 24.71°, and the relative diffraction intensities of the diffraction ...

Embodiment 2

[0029] Embodiment 2: Preparation of 1 / 4 water ceftezole sodium compound

[0030] At room temperature, dissolve 75.05g of sodium citrate in 400ml of acetonitrile and 100ml of water mixture, then add 100.02g of ceftezole and stir to dissolve, adjust the pH value to 5.0 with citric acid, add 5.03g of activated carbon and stir for 30 minutes to adsorb , decarbonized by suction filtration; washed the filter cake with 50ml of acetonitrile; lowered the temperature of the filtrate to 0°C, slowly added dichloromethane dropwise under stirring for 2h, filtered under reduced pressure, washed the filter cake with 50ml of dichloromethane, and dried under reduced pressure at 40°C After 3.5 hours, 81.55 g of ceftezole sodium compound in 1 / 4 water was obtained.

[0031]The powder X-ray diffraction pattern has characteristic diffraction peaks at the diffraction angles 2θ of 9.08°, 18.16°, 18.93°, 21.57°, 22.20°, 23.57°, and 24.75°, and the relative diffraction intensities of the diffraction ang...

Embodiment 3

[0034] Embodiment 3: Preparation of 1 / 4 water ceftezole sodium compound

[0035] At room temperature, dissolve 75.01g of sodium citrate in 450ml of acetonitrile and 150ml of water mixture, then add 100.06g of ceftezole and stir to dissolve, adjust the pH value to 4.5 with citric acid, add 6.07g of activated carbon and stir for 30 minutes to adsorb , decarbonized by suction filtration; washed the filter cake with 50ml of acetonitrile; lowered the temperature of the filtrate to 5°C, slowly added dichloromethane dropwise with stirring for 2h, filtered under reduced pressure, washed the filter cake with 50ml of dichloromethane, and dried under reduced pressure at 50°C After 3 hours, 85.06 g of ceftezole sodium compound in 1 / 4 water was obtained.

[0036] The powder X-ray diffraction pattern has characteristic diffraction peaks at the diffraction angles 2θ of 9.03°, 18.19°, 18.90°, 21.50°, 22.15°, 23.52°, and 24.70°, and the relative diffraction intensities of the diffraction angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com