A kind of preparation method of I-type ceftezole sodium crystal

A technology of ceftezole sodium and ceftezole acid, which is applied in the field of medicine, can solve problems such as inability to obtain ceftezole sodium crystals, difficulty in ensuring a product with uniform properties, and poor repeatability of the preparation process, so as to improve stability and safety, Low cost, good effect of crystal morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

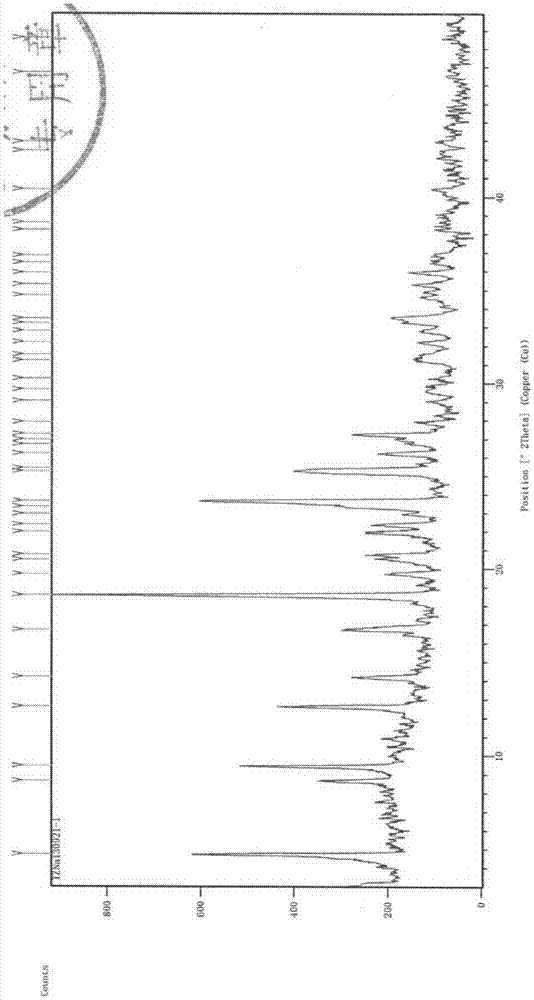

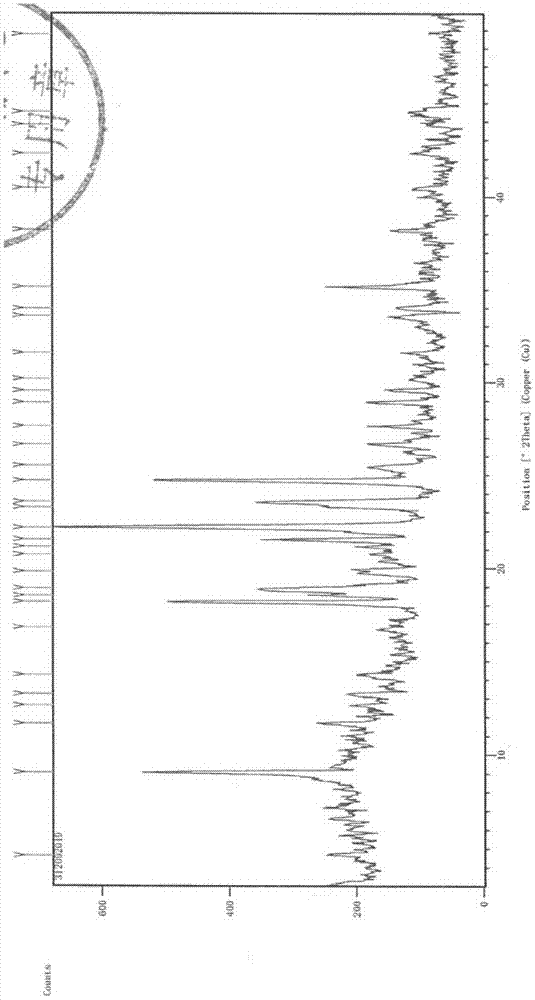

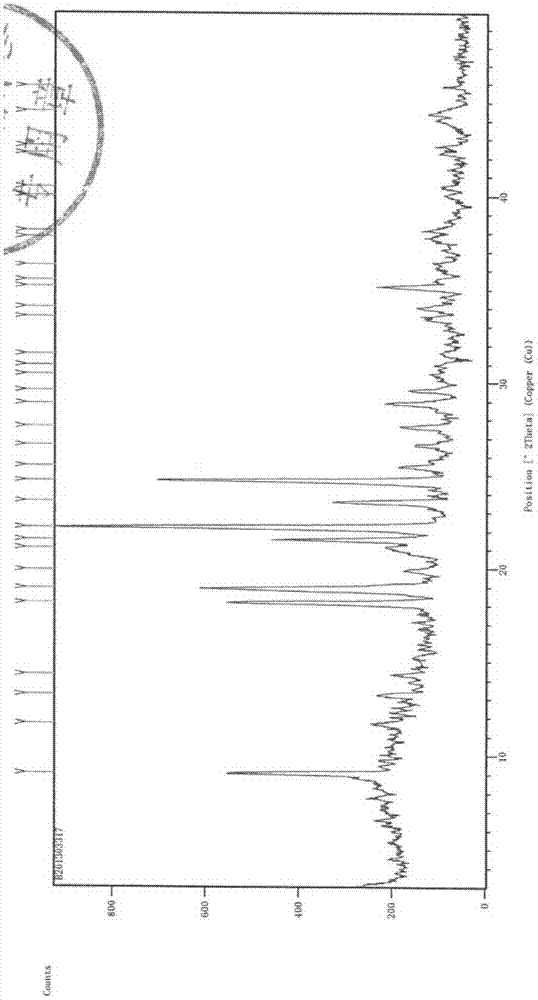

[0060] Experimental example 1 X-ray diffraction (XRD) experiment

[0061] Testing instrument: Empyrean X-ray diffractometer;

[0062] Detection condition: Cu target Kα 1 Ray, voltage 40kV, current 40mA, divergence slit 1 / 32°, anti-scatter slit 1 / 16°, anti-scatter slit 7.5mm, 2θ range: 3°~50°, step size 0.02°, dwell time at each step 40s;

[0063] Detection basis: Pharmacopoeia of the People's Republic of China (2010 Edition Part Two) Appendix IXFX-Ray Powder Diffraction Method.

experiment example 2

[0064] Experimental example 2 Thermogravimetric analysis experiment

[0065] Testing instrument: Germany NETZSCH company TG209 thermogravimetric analyzer;

[0066] Detection conditions: atmosphere: air, 20Ml / min; scanning program: room temperature ~ 350°C, heating rate: 10°C / min;

[0067] Testing basis: General Rules for Thermal Analysis Methods JY / T 014-1996.

experiment example 3

[0068] Experimental Example 3 Polarizing microscope test

[0069] Testing instrument: SMART-POL polarizing microscope of Chongqing Auto Optical Instrument Co., Ltd.;

[0070] Detection conditions: eyepiece 10 times, objective lens 10 / 0.25 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com