A heat dissipation device for a temperature control system of a PCR detector

A technology of temperature control system and heat dissipation device, which is applied in biochemical cleaning devices, enzymology/microbiology devices, bioreactors/fermenters for specific purposes, etc., can solve the problems of occupying instrument space and disadvantageous instrument miniaturization. , to achieve the effect of high heat dissipation efficiency, rapid and effective heat dissipation, and reduced space occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

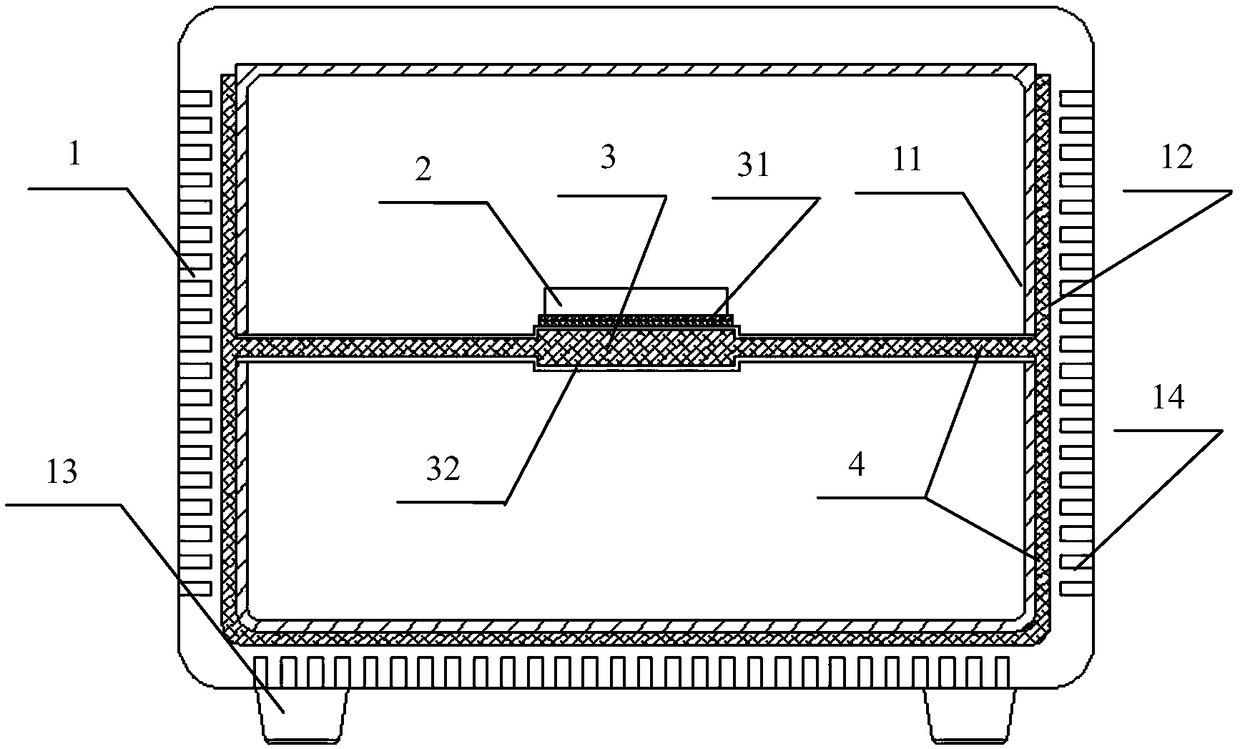

[0022] Implementation Case 1: If figure 1 As shown, a heat dissipation device for a temperature control system of a PCR detector includes a temperature control system 2 , a heat conduction mechanism 3 and a heat dissipation chassis 1 .

[0023] The temperature control system 2 is the temperature control system and structure required for the operation of the PCR detector, and mainly includes heating and cooling devices (such as semiconductor cooling chips) and fixed structures.

[0024] The heat conduction mechanism 3 includes a heat conduction metal layer 32 , a heat conduction pipe 33 , a heat conduction liquid 4 , etc., and the heat conduction mechanism 3 transfers and dissipates heat to ensure the normal operation of the temperature control system 2 . The heat-conducting metal layer 32 is closely attached to the heat-generating and cooling device of the temperature control system 2 that needs to be dissipated through a heat-conducting medium 31 such as graphite sheet or hea...

Embodiment example 2

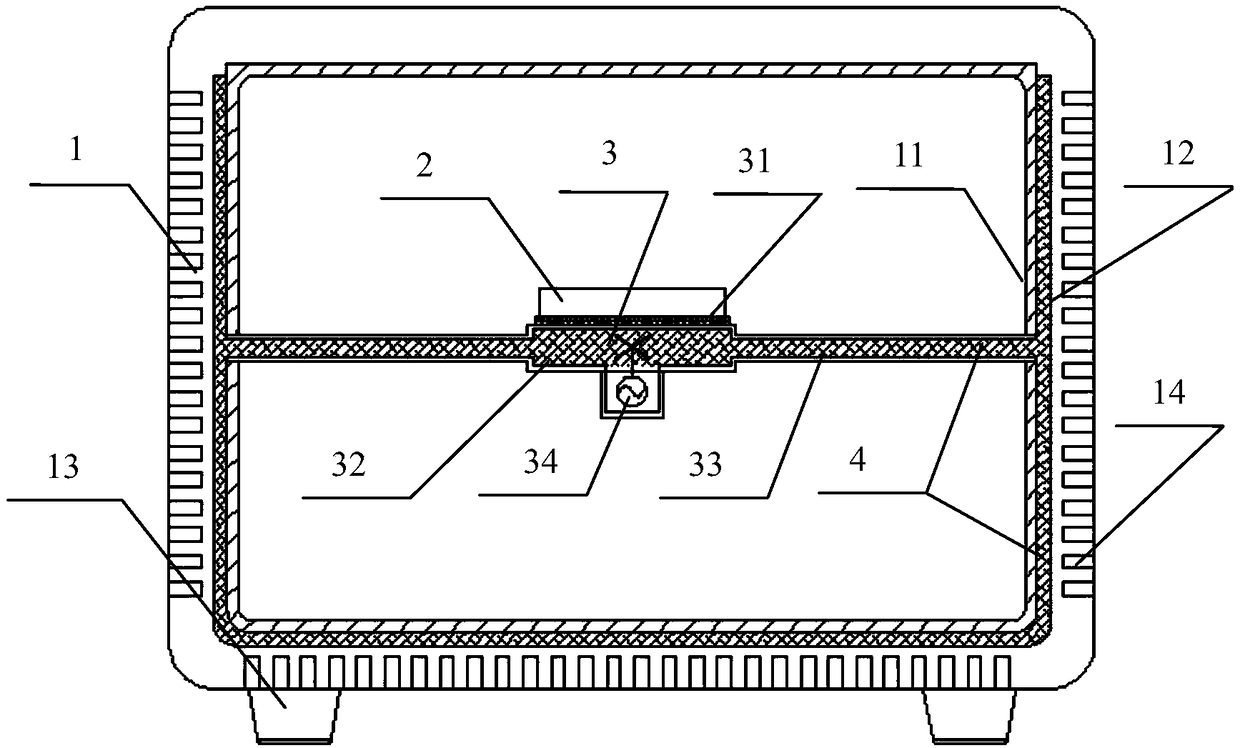

[0028] Implementation Case 2: If figure 2 As shown, adding a micropump 34 on the basis of the implementation case 1 according to actual needs can speed up the circulation speed of the heat transfer liquid, thereby accelerating heat dissipation and improving heat dissipation efficiency. Specifically, a device for cooling the temperature control system of a PCR detector includes a temperature control system 2 , a heat conduction mechanism 3 and a cooling case 1 . A PCR detector that meets higher requirements for temperature control and cooling systems.

[0029] The temperature control system 2 is the temperature control system and structure required for the operation of the PCR detector, and mainly includes heating and cooling devices (such as semiconductor cooling chips) and fixed structures.

[0030] The heat conduction mechanism 3 includes a heat conduction metal layer 32 , a heat conduction pipe 33 , a micropump 34 and a heat conduction liquid 4 , etc. The heat conduction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com