Tail gas processing system

A technology for exhaust gas treatment and exhaust gas collection, which is applied in the directions of gas treatment, use of liquid separation agent, combined device, etc., can solve the problems of blockage, difficult cleaning of exhaust gas treatment device, and high energy consumption of adhesive film paper.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better understand the present invention, the content of the present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments, but the content of the present invention is not limited to the following embodiments.

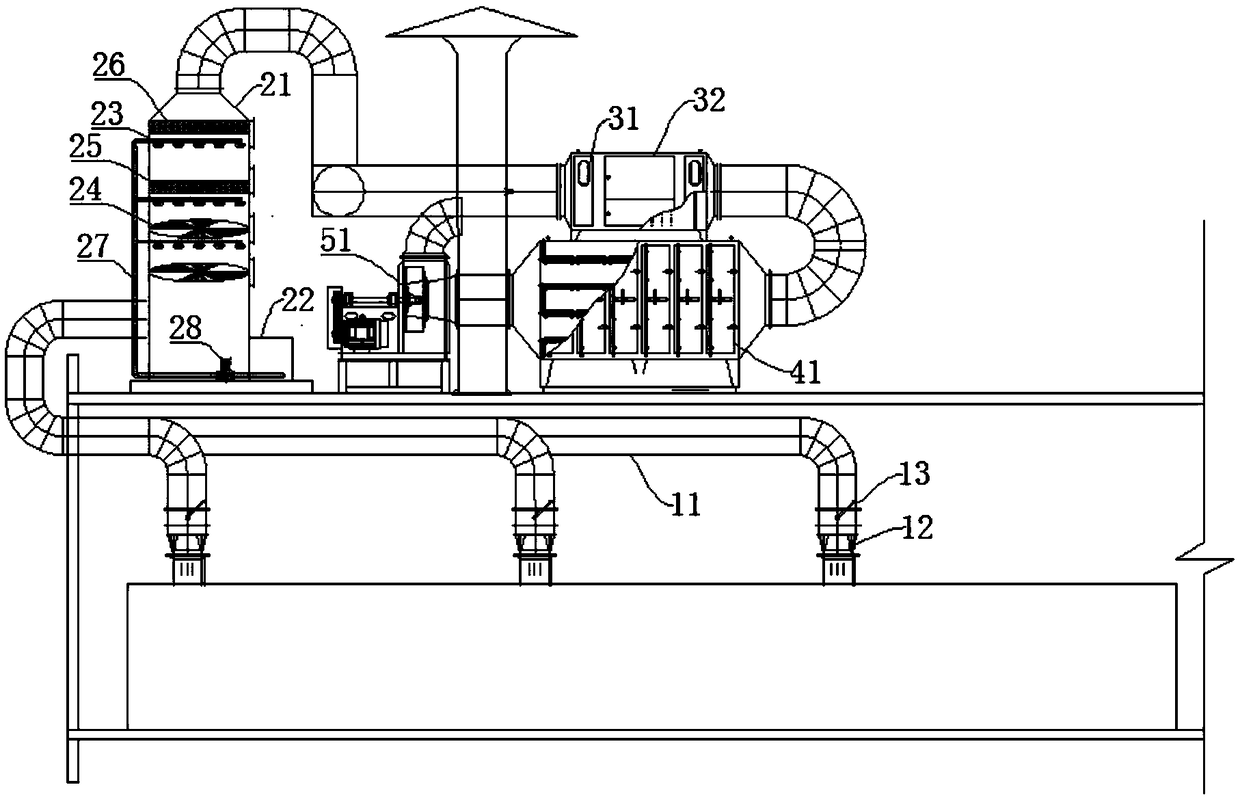

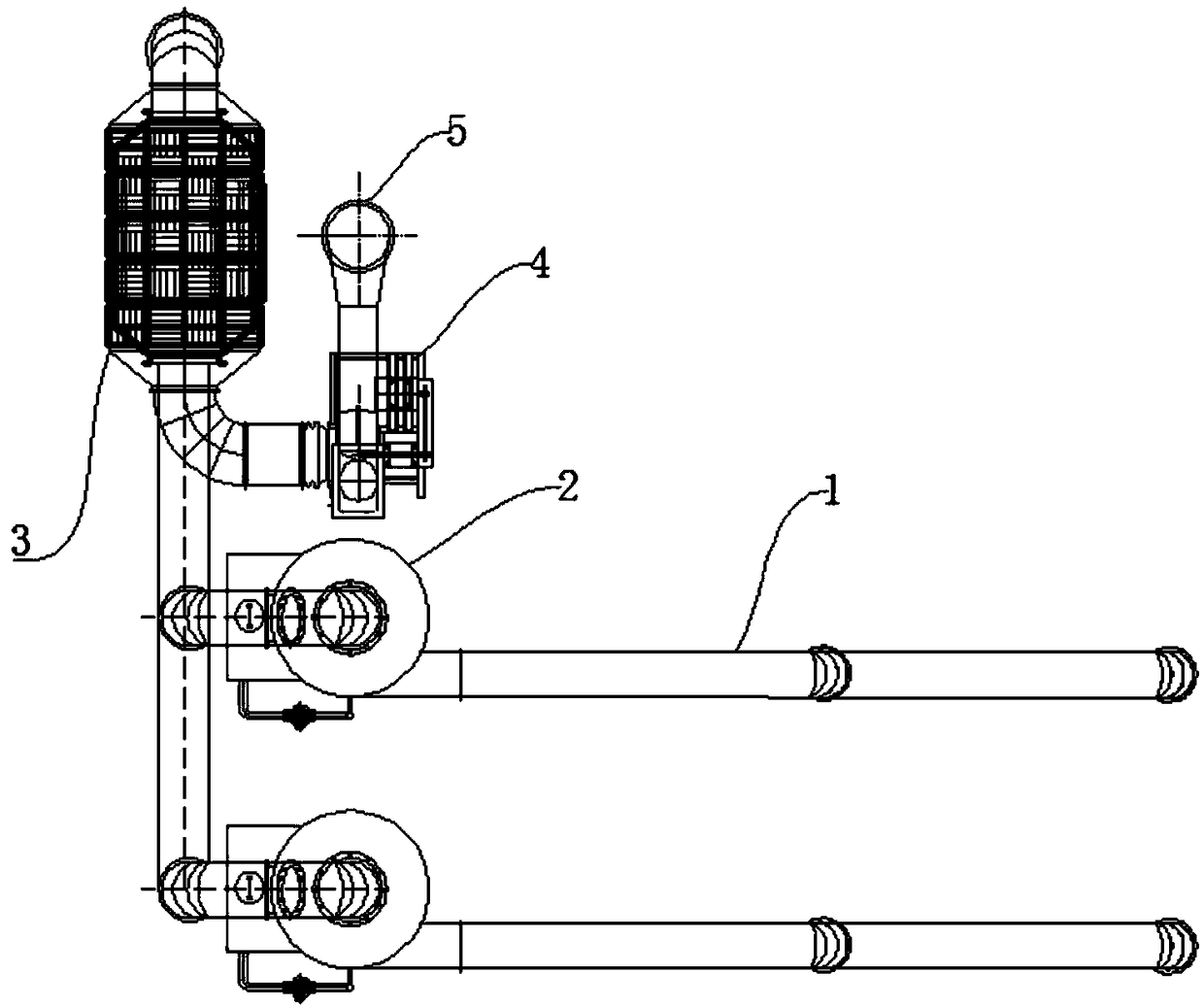

[0019] The present invention provides a tail gas treatment system, comprising a tail gas collection device 1, a spray tower device 2, a photocatalytic device 3, an activated carbon absorption device 4 and a chimney 5 connected in series through pipelines in sequence,

[0020] Wherein, the spray tower device 2 includes a tower body 21, the lower end of the tower body is provided with an air inlet, the upper end of the tower body is provided with an air outlet, and the tower body 21 is sequentially provided with swirl plates from bottom to top. 24. Packing layer 25 and anti-fog packing layer 26;

[0021] Also be provided with water circulation device in described tower body 21, described water c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com