Cooling device for hot continuous rolling intermediate billet and using method thereof

A technology of cooling device and hot continuous rolling, which is applied in the direction of workpiece cooling device, metal rolling, metal rolling, etc., can solve the problems such as the reduction of rolling efficiency, achieve the difficulty of transformation, improve the coarseness of austenite grains, and improve the quality of equipment. small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

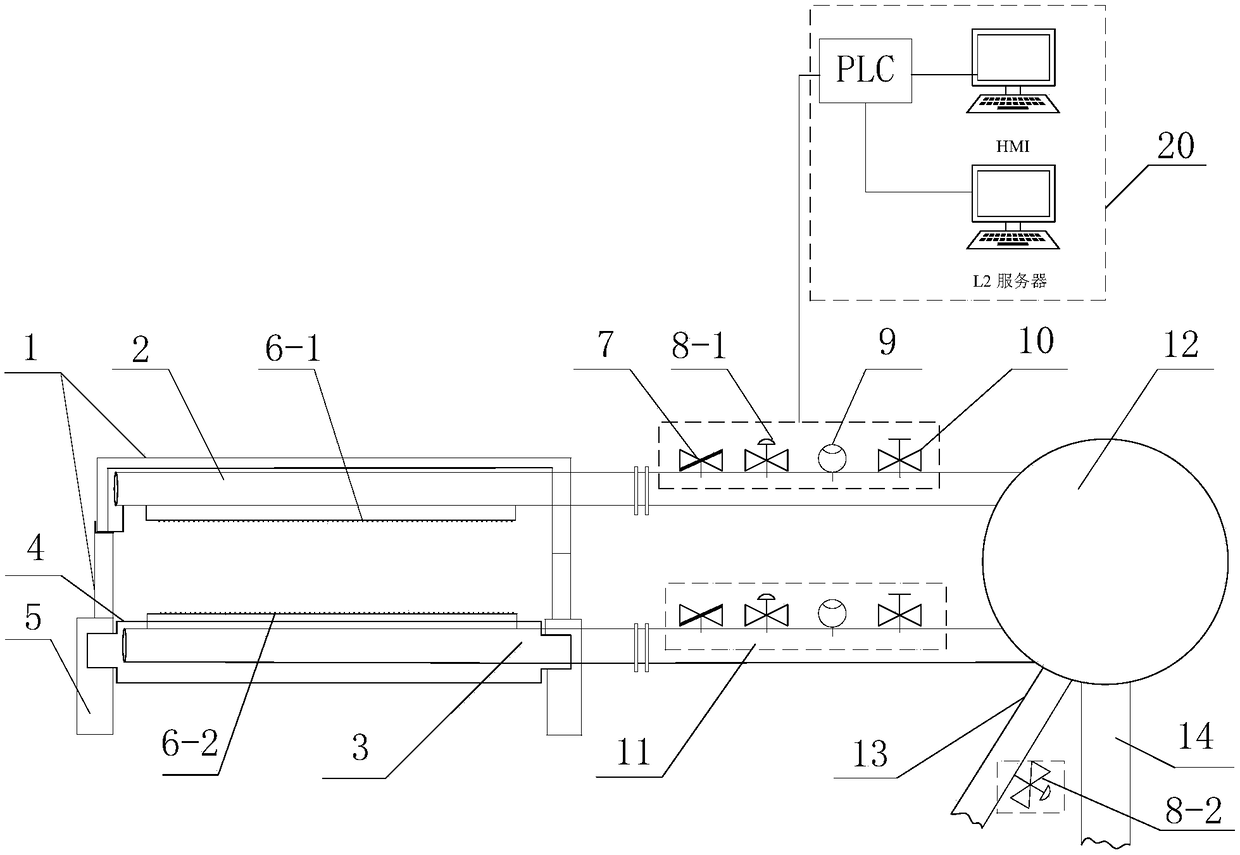

[0046] A hot continuous rolling intermediate billet cooling device, its structure schematic diagram is shown in figure 1 , specifically including the rapid cooling system of the intermediate billet, the water supply system and the automatic control system;

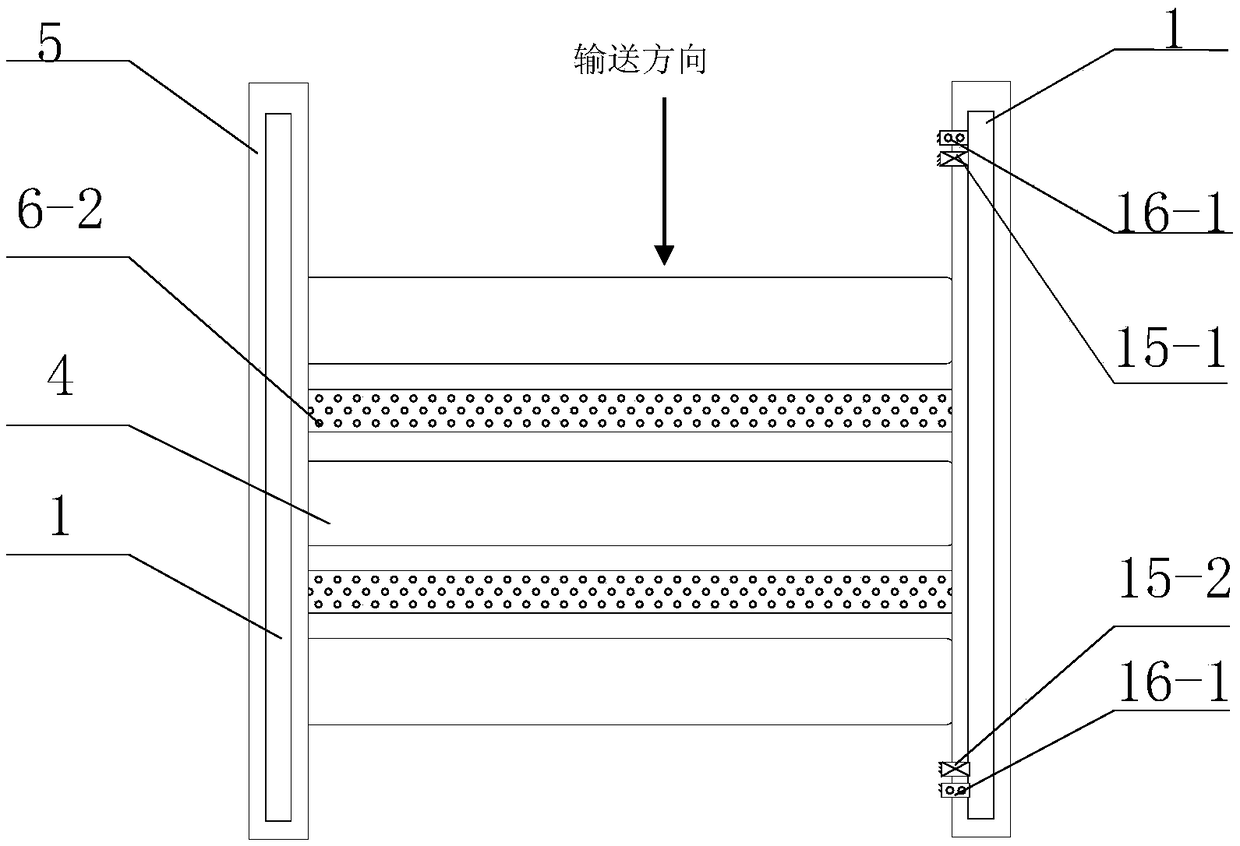

[0047] The intermediate billet rapid cooling system is arranged at the hot continuous rolling conveying roller table, figure 1 The installation direction of the device is perpendicular to the conveying direction of the hot continuous rolling conveying roller table. The rapid cooling system of the intermediate billet includes the equipment main frame 1, the upper header 2, the lower header 3, the air spray device and the high-pressure side spray device, specifically :

[0048] The main body frame 1 of the equipment is arranged at the hot continuous rolling conveying roller table, and is connected with the hot continuous rolling roller table frame 5;

[0049] The upper header 2 is arranged above the hot continuous rolling ...

Embodiment 2

[0064] A hot continuous rolling intermediate slab cooling device, same as embodiment 1.

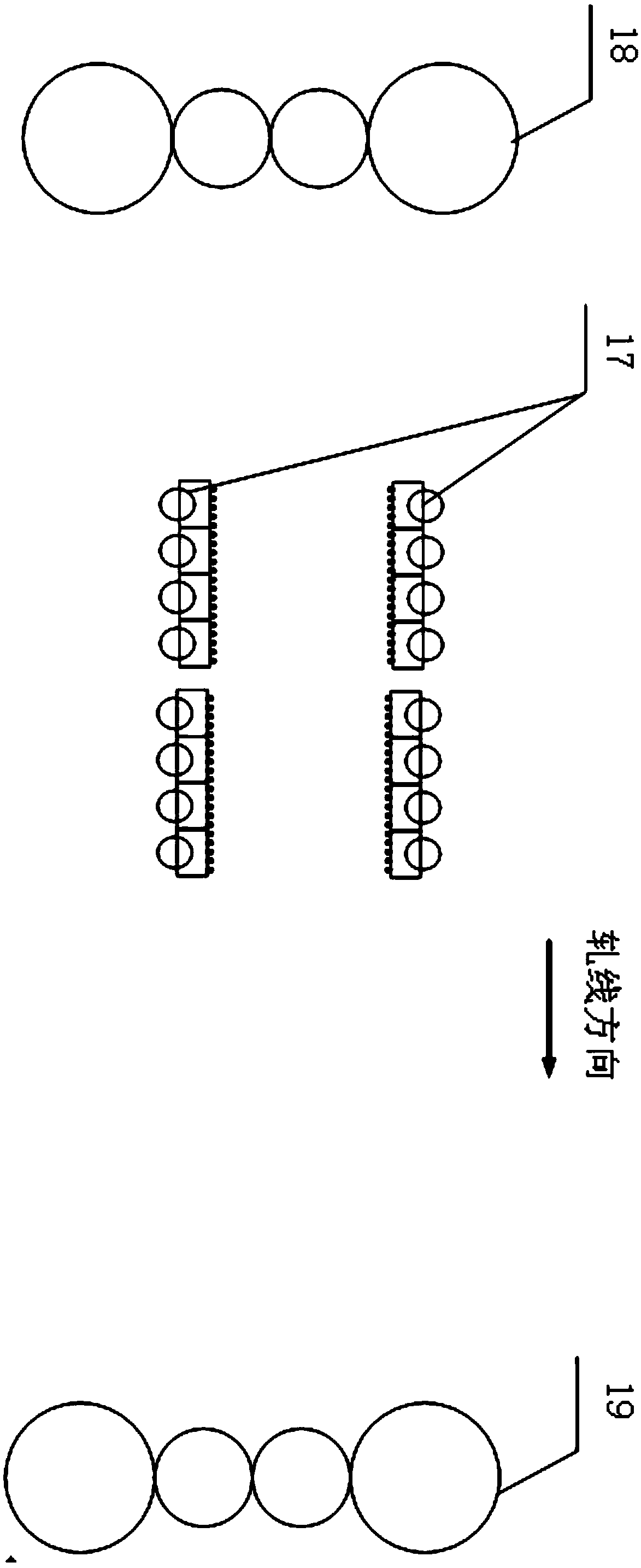

[0065] A method for using a hot continuous rolling intermediate slab cooling device, using such as Figure 4 The arrangement method shown includes the following steps:

[0066] The hot continuous rolling intermediate billet cooling device adopts the second process arrangement method, that is, the hot continuous rolling intermediate billet cooling device 17 is arranged between the rough rolling mill and the finishing mill, close to the finishing mill side, 35m away from the center line of the first finishing stand, and the hot rolling mill Continuous rolling intermediate slab cooling device, including 4 pairs of cooling headers.

[0067] In this embodiment, the cooling water pressure is controlled at 0.8 MPa, and the water volume of a single header is 220-320 m3 / h. Taking the production of X70 pipeline steel with a thickness of 22mm as an example, after rough rolling R2, the thickness of...

Embodiment 3

[0069] A hot continuous rolling intermediate slab cooling device, same as embodiment 1.

[0070] A method for using a hot continuous rolling intermediate slab cooling device, using such as Figure 5 The arrangement method shown includes the following steps:

[0071] The hot continuous rolling intermediate billet cooling device adopts the third process layout method. The hot continuous rolling intermediate billet cooling device 17 is arranged at the entrance and exit of the rough rolling R2 stand 18, and the hot continuous rolling intermediate billet cooling device 17 is 5m away from the center line of the roughing mill. , The hot continuous rolling intermediate billet cooling device 17 arranged at the entrance of the rough rolling mill includes 2 pairs of cooling headers, and the hot continuous rolling intermediate billet cooling device 17 arranged at the exit of the rough rolling mill includes 2 pairs of cooling headers. The cooling water pressure is controlled at 0.8MPa, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com