Repairing device for PVC/PVG whole-core flame-retardant conveyer belt

A technology of conveyor belt and flat vulcanizer, which is applied in the field of repairing devices for whole-core flame-retardant conveyor belts, can solve the problems of failure rate, high maintenance rate, long production cycle, uneconomical, etc., so as to solve the problem of repairing process and improve the surface quality. , the effect of no pollutant emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

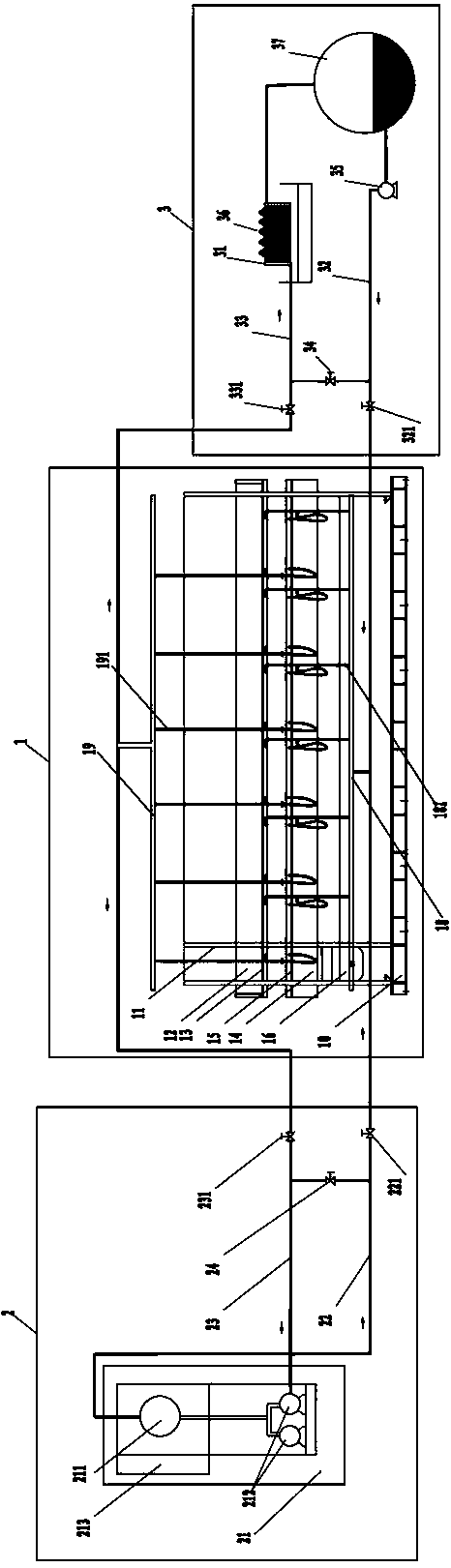

[0014] The present invention includes a flat vulcanizing machine 1, a heating circulation system 2, a cooling circulation system 3 and related pipelines and valves.

[0015] The flat vulcanizer 1 is a conventional flat vulcanizer, comprising a frame plate 11, an upper joist 12, an upper hot plate 13, a lower joist 14, a lower hot plate 15, a hydraulic cylinder 16, a hydraulic station 17 and related connection and fixing devices . The upper hot plate 13 and the lower hot plate 15 adopt the low-in and high-out mode of oil inlet, that is, the oil inlet main pipe 18 is arranged at the bottom of the flat vulcanizing machine 1, and the oil outlet main pipe 19 is arranged at the top. Described oil inlet main pipe 18 is connected with oil inlet branch pipe 181, and described oil outlet main pipe 19 is connected with oil outlet branch pipe 191.

[0016] The heating cycle system 2 includes a heat transfer oil furnace 21, an oil outlet pipe I22, an oil return pipe I23, a circulation con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com