Nanometer molybdenum disulfide grinding aid and preparation method thereof

A technology of molybdenum disulfide and grinding aid, which is applied in the field of concrete production and processing, can solve the problems that are not very suitable for industrial production process, can not improve the characteristics of grinding aid, and the price of graphene is high, so as to protect human health and excellent tribological performance , the effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

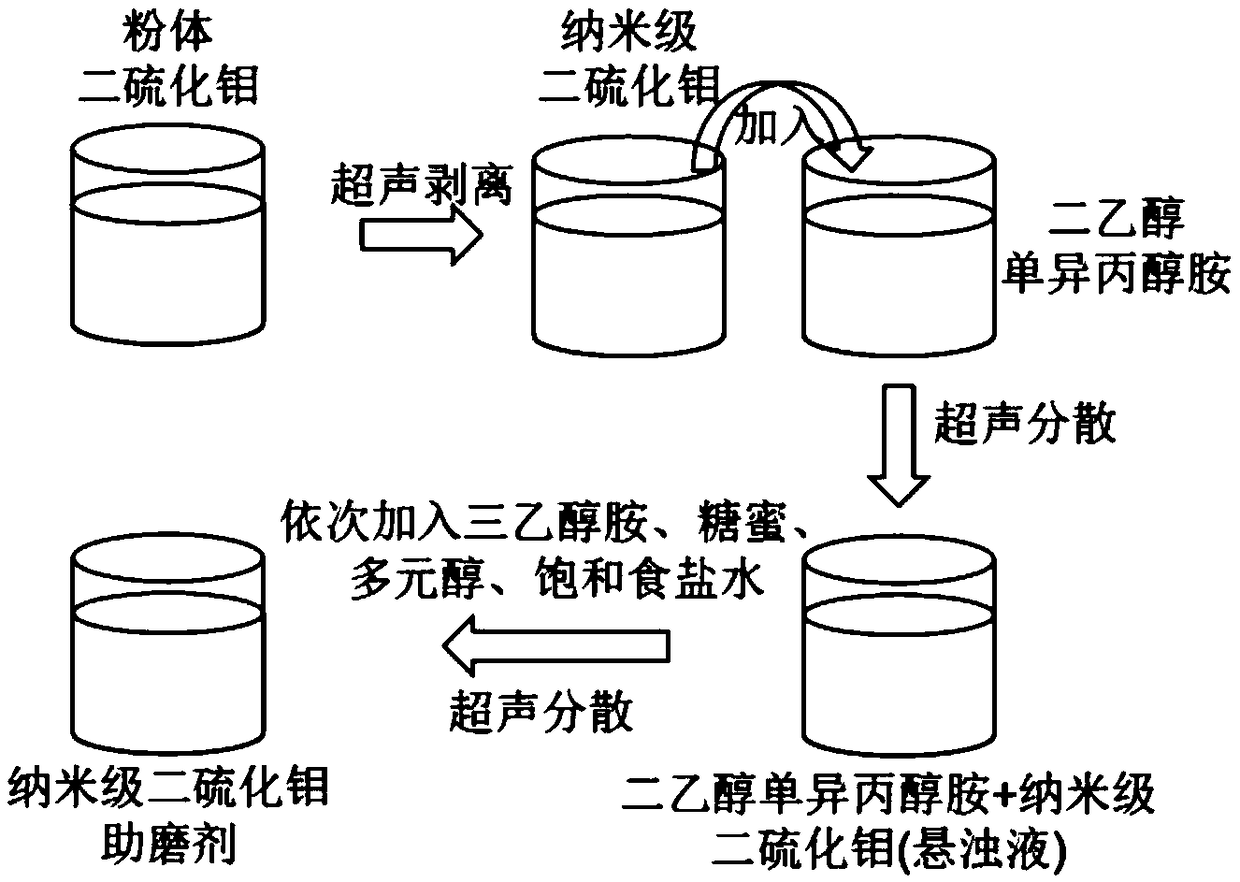

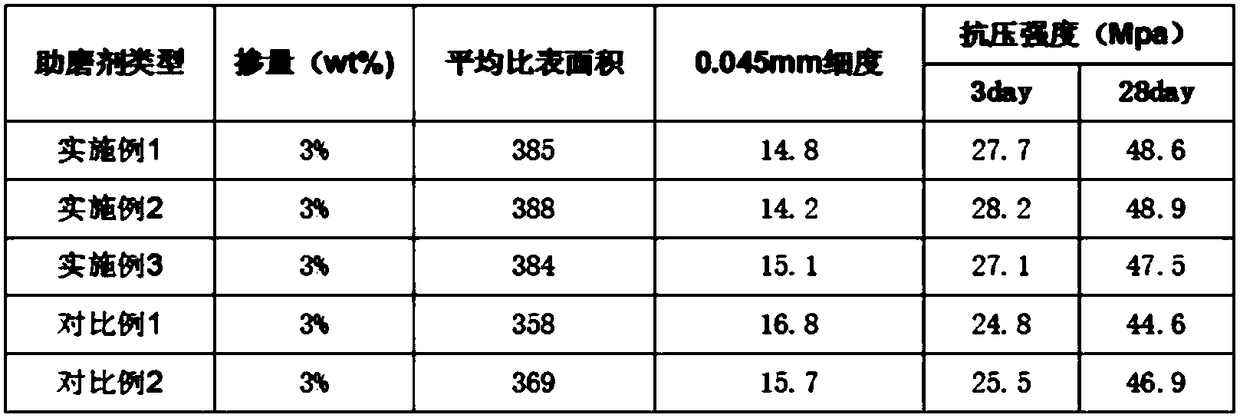

[0027] A nano-scale molybdenum disulfide grinding aid, which is composed of the following raw materials in mass percentage: 32% diethanol monoisopropanolamine, 7% triethanolamine, 8% molybdenum disulfide dispersion, molasses 11%, polyether polyol 11% %, 28% saturated salt water, and 3% remaining water; the specific preparation process includes the following steps:

[0028] Add the weighed molybdenum disulfide dispersion (20mg / ml) into diethanol monoisopropanolamine and ultrasonically disperse for 20min; then add the weighed triethanolamine, molasses, polyol, saturated saline and water in sequence and ultrasonically 10min; Finally, after stirring for 20 minutes, stand still for 12 hours to obtain nano-scale molybdenum disulfide grinding aid.

[0029] Wherein the molybdenum disulfide dispersion liquid preparation step comprises: adding 16g molybdenum disulfide block into 1000ml water, ultrasonic dispersion 30min; Adding 100ml concentration is the hydrochloric acid of 1mol / L in t...

Embodiment 2

[0031] A nano-scale molybdenum disulfide grinding aid, which is composed of the following raw materials in mass percentage: 30% diethanol monoisopropanolamine, 8% triethanolamine, 8% molybdenum disulfide dispersion, 12% molasses, and 12% polyether polyol %, 25% saturated saline, and 5% remaining water; the specific preparation process includes the following steps:

[0032] Add the weighed molybdenum disulfide dispersion (20mg / ml) into diethanol monoisopropanolamine and ultrasonically disperse for 20min; then add the weighed triethanolamine, molasses, polyol, saturated saline and water in sequence and ultrasonically 10min; Finally, after stirring for 20 minutes, stand still for 12 hours to obtain nano-scale molybdenum disulfide grinding aid.

[0033] Wherein the molybdenum disulfide dispersion preparation step comprises: adding 16g of molybdenum disulfide blocks into 1000ml of water, ultrasonically dispersing for 30 minutes; adding 100ml of hydrochloric acid with a concentratio...

Embodiment 3

[0035] A nano-scale molybdenum disulfide grinding aid, which is composed of the following raw materials in mass percentage: 33% of diethanol monoisopropanolamine, 7% of triethanolamine, 7% of molybdenum disulfide dispersion, 11% of molasses, and 11% of polyether polyol %, 30% of saturated saline, and 1% of remaining water; the specific preparation process includes the following steps:

[0036] Add the weighed molybdenum disulfide dispersion (20mg / ml) into diethanol monoisopropanolamine and ultrasonically disperse for 20min; then add the weighed triethanolamine, molasses, polyol, saturated saline and water in sequence and ultrasonically 10min; Finally, after stirring for 20 minutes, stand still for 12 hours to obtain nano-scale molybdenum disulfide grinding aid.

[0037] Wherein the molybdenum disulfide dispersion preparation step comprises: adding 16g of molybdenum disulfide blocks into 1000ml of water, ultrasonically dispersing for 30 minutes; adding 100ml of hydrochloric aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com