Aerobic composting method

An aerobic composting and composting technology, which is applied in the field of solid waste recycling, can solve the problems of long composting cycle, low efficiency, and slow community succession, so as to increase nitrogen content and fertilizer efficiency, improve the sanitary environment, and prevent nitrogen loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

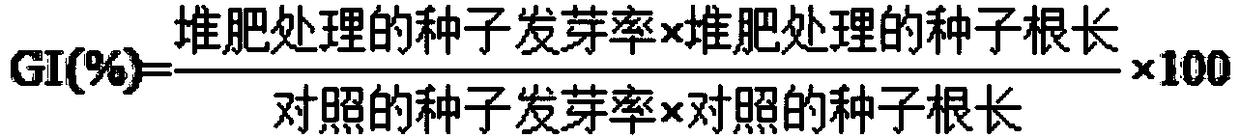

Method used

Image

Examples

Embodiment 1

[0032] In this example, the specific steps for rapid aerobic composting of excess sludge and corn stalks by using sewage from a food factory are as follows:

[0033] (1) Mixing: Mix the excess sludge and corn stalks from food factory sewage treatment in a ratio of 6:4. The moisture content of the excess sludge and stalks are 85% and 9% respectively, and then add the mixture of excess sludge and corn stalks The buffer substance composed of dipotassium hydrogen phosphate and potassium dihydrogen phosphate with a mass of 1%, the molar ratio of dipotassium hydrogen phosphate and potassium dihydrogen phosphate is 2.5:1, after mixing, put it into a composting reactor and keep stirring.

[0034] (2) Staged rapid aerobic composting: control the composting temperature at 35°C, compost for 24 hours, and the ventilation volume is 7.5m 3 / h, during the composting process, the pH dropped from 7.10 to 6.67; then the composting temperature was controlled at about 55°C, composting for 46 hour...

Embodiment 2

[0037] In this example, the specific steps for rapid aerobic composting of excess sludge and corn stalks by using sewage from a food factory are as follows:

[0038] (1) Mixing: Mix the excess sludge and corn stalks from food factory sewage treatment in a ratio of 6:4. The moisture content of the excess sludge and stalks are 85% and 9% respectively, and then add the mixture of excess sludge and corn stalks The buffer substance composed of dipotassium hydrogen phosphate and potassium dihydrogen phosphate with a mass of 0.5%, the molar ratio of dipotassium hydrogen phosphate and potassium dihydrogen phosphate is 3:1, after mixing, put it into a composting reactor and keep stirring.

[0039] (2) Staged rapid aerobic composting: control the composting temperature at 35°C, compost for 24 hours, and the ventilation volume is 7.5m 3 / h, the pH dropped from 7.06 to 6.54 during the composting process; then the composting temperature was controlled at about 55°C, composting for 46 hours...

Embodiment 3

[0042] In this example, the specific steps for rapid aerobic composting of excess sludge and corn stalks by using sewage from a food factory are as follows:

[0043] (1) Mixing: Mix the remaining sludge and corn stalks from the food factory sewage treatment in a ratio of 6:4. The moisture content of the remaining sludge and straw is 85% and 9% respectively, and then add the remaining sludge and corn stalks The straw mixture is composed of 3% potassium hydrogen phosphate and potassium dihydrogen phosphate as a buffer substance, and the molar ratio of dipotassium hydrogen phosphate and potassium dihydrogen phosphate is 0.2:1. After mixing, put it into a compost reactor and keep stirring.

[0044] (2) Staged rapid aerobic composting: control the composting temperature at 35°C, compost for 24 hours, and the ventilation volume is 7.5m 3 / h, the pH drops from 6.96 to 6.5 during the composting process; then the composting temperature is controlled at about 55°C, composting for 46 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com