Method for synthesizing cyclohexanone by accelerating hydrogenation of aromatic compounds with carbon dioxide

A technology of aromatic compounds and carbon dioxide, which is applied in the synthesis field of aromatic compounds to synthesize cyclohexanone, can solve the problems of low conversion rate, complex products, harsh reaction conditions, etc., and achieve the effect of alleviating environmental problems, simple process operation, green and safe cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The catalyst used in this example is commercial 10% Pd / C.

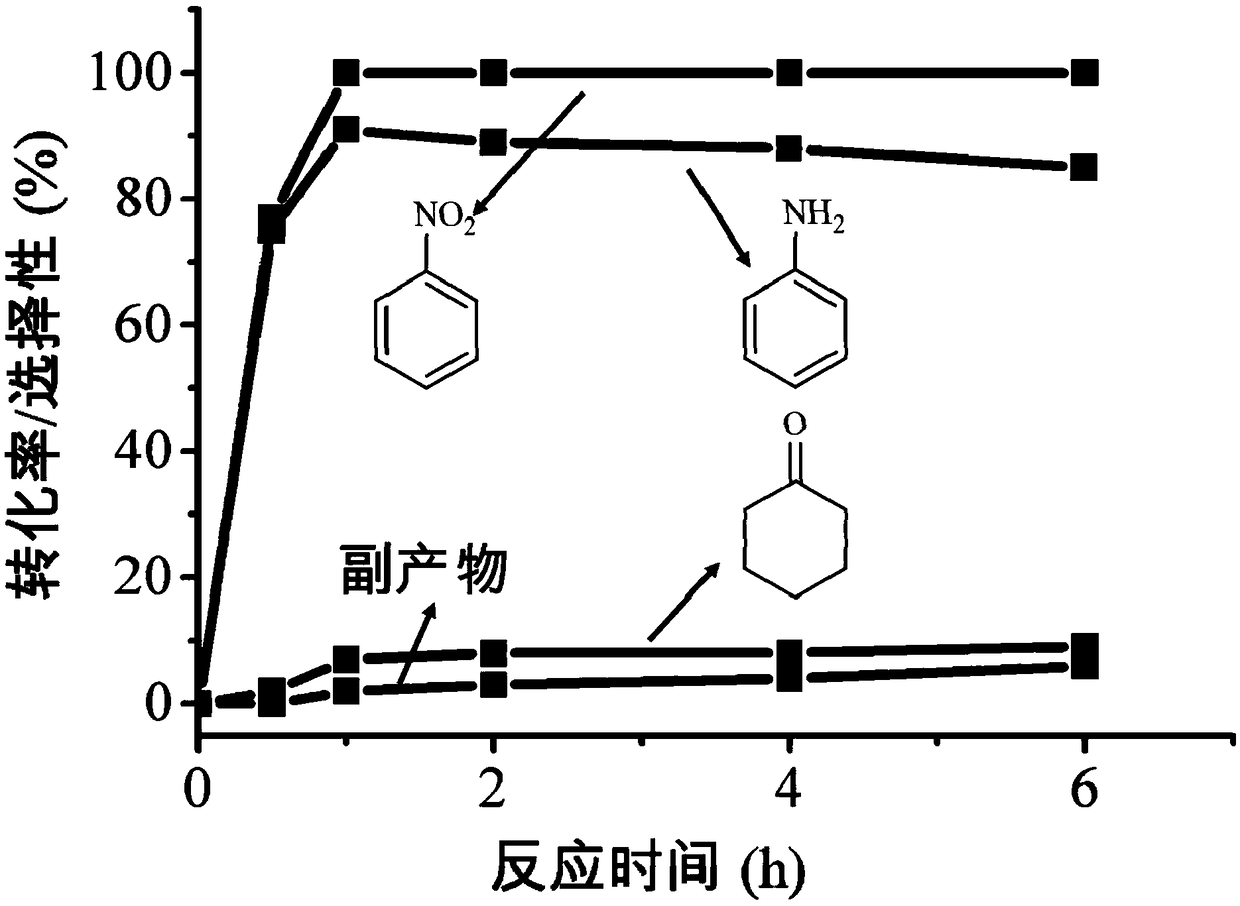

[0041] Reaction steps: Accurately weigh 10 mg of 10% Pd / C catalyst and 0.25 mmol of nitrobenzene into a reaction flask, and then add 5 mL of water as a solvent. and filled with CO through the air bag 2 and H 2(molar ratio is 1:3), add CO 2 and H 2 The post-reaction pressure is 0.1 MPa, the reaction temperature is 35°C, and after 6 hours of reaction, the yield of the final product cyclohexanone can reach 90%.

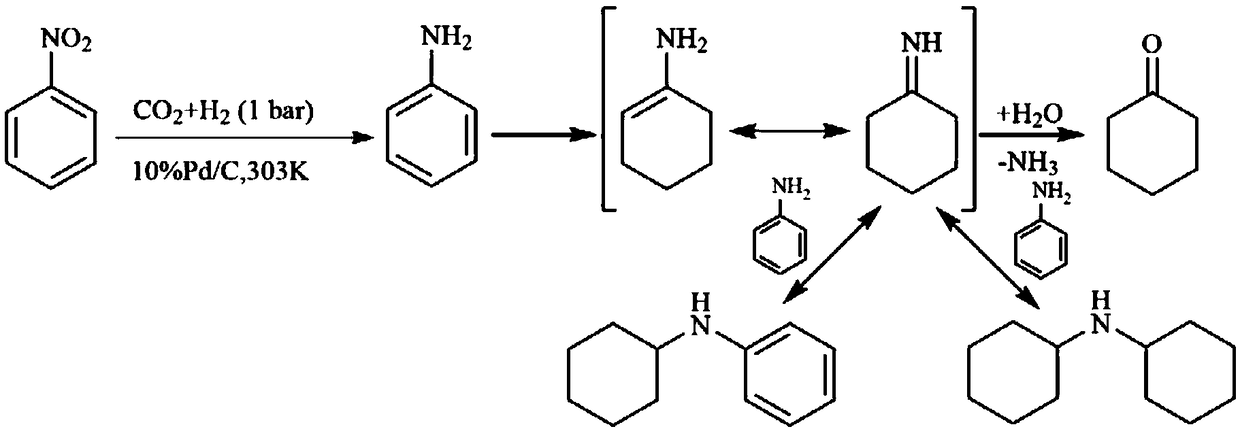

[0042] figure 1 for the ligand CO in the gas phase 2 With the help of palladium nanoparticles catalyzed hydrogenation of nitrobenzene to produce cyclohexanone, the gas phase ligand CO 2 With the help of nitrobenzene and under the action of Pd / C catalyst, the nitro group in nitrobenzene is reduced to amine group to generate aniline, and then the benzene ring in aniline undergoes hydrogenation reaction and hydrolyzes to remove ammonia with the help of water , which is further reduced to cyclohexanone...

Embodiment 2

[0047] The catalyst used in this example is commercial 10% Pd / C.

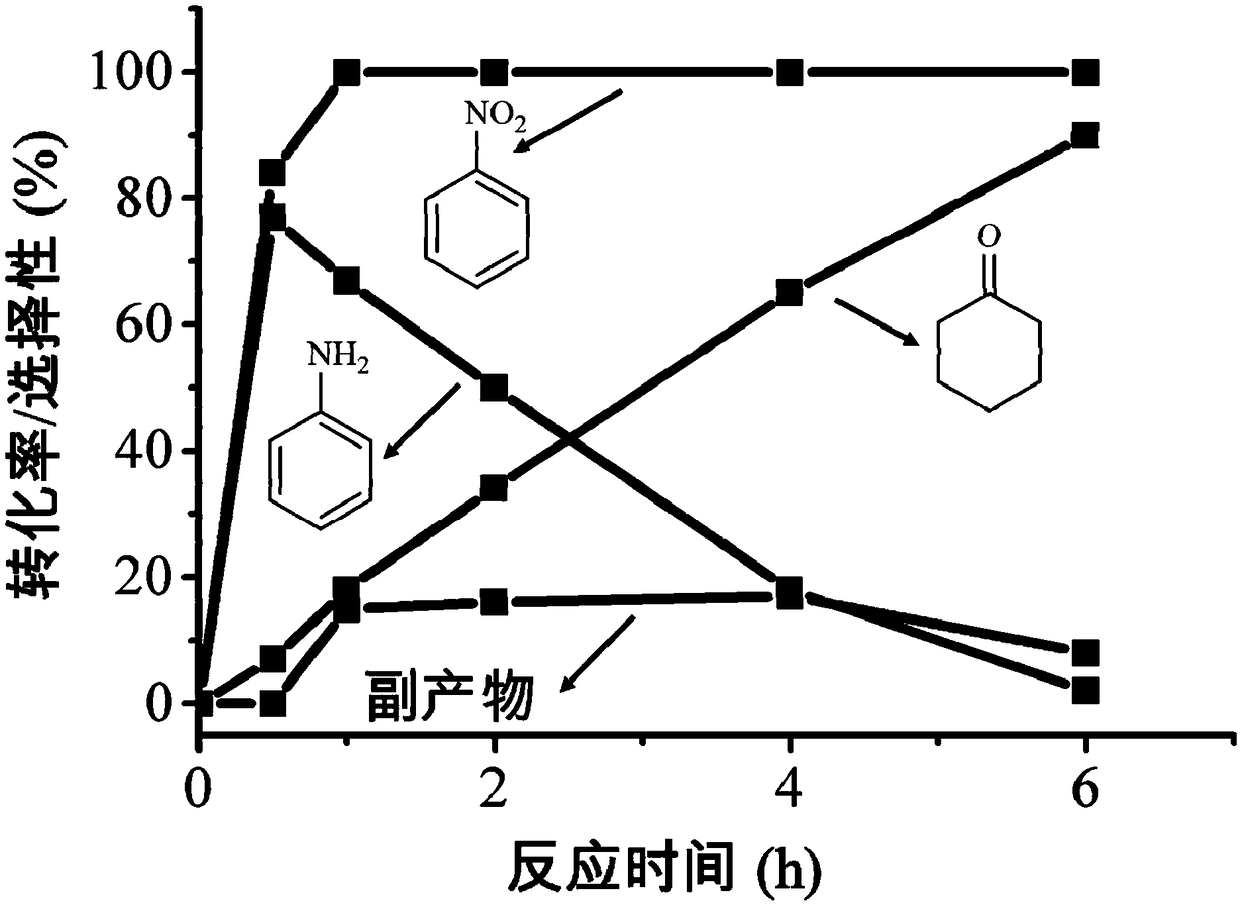

[0048] Accurately weigh 10 mg of 10% Pd / C catalyst and 0.25 mmol of aniline into the reaction flask, and then add 5 mL of water as a solvent. and filled with CO through the air bag 2 and H 2 (molar ratio is 1:3), add CO 2 and H 2 The post-reaction pressure is 0.1 MPa, the reaction temperature is 35° C., and after 6 hours of reaction, the yield of the final product cyclohexanone can reach 28%.

Embodiment 3

[0050] The catalyst used in this example is commercial 10% Pd / C.

[0051] Accurately weigh 10 mg of 10% Pd / C catalyst and 0.25 mmol of N-methylaniline into the reaction flask, and then add 5 mL of water as a solvent. and filled with CO through the air bag 2 and H 2 (molar ratio is 1:3), add CO 2 and H 2 The final reaction pressure is 0.1 MPa, the reaction temperature is 35°C, and the yield of the final product can reach 99% after 6 hours of reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com