Cholesterol extraction process

A cholesterol and process technology, applied in the field of cholesterol extraction process, can solve the problems of high cost and low extraction efficiency, and achieve the effects of low cost, thorough extraction and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

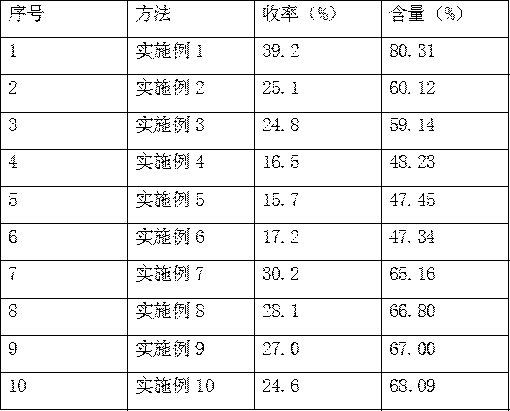

Examples

Embodiment 1

[0044] ① pulverize pig brain to obtain pig brain homogenate;

[0045] ②Add extraction solvent to pig brain homogenate: methanol:chloroform=2.3:1v / v, pig brain homogenate: extraction solvent=1:10.6 w / v, stir and extract at 0~30°C for 6 hours to obtain extract;

[0046] ③ filtering the extract, concentrating the filtered liquid to obtain a concentrated solution, and recovering the solvent at the same time;

[0047] ④ Add methanol solution containing 10v / v% concentrated sulfuric acid containing 10 times the mass of the concentrated solution to the concentrated solution, reflux and hydrolyze at 70°C for 24 hours, filter the refluxed liquid, and crystallize the filtered liquid at 0°C for 12~72h to obtain Crystals;

[0048] ⑤Filtrate the crystals in step ④, add methanol according to 4.2 times the mass of the crystals, raise the temperature to 70°C until the crystals dissolve, reflux at 70°C for 1 hour, place the refluxed liquid at 0°C, and crystallize for 12~72h;

[0049] ⑥Filtrate ...

Embodiment 2

[0053] ① pulverize pig brain to obtain pig brain homogenate;

[0054] ②Add extraction solvent to pig brain homogenate: methanol:ethanol=1~5:1v / v, pig brain homogenate:extraction solvent=1:10w / v, stir and extract at 0~30°C for 6 hours to obtain extract;

[0055] ③ filtering the extract, concentrating the filtered liquid to obtain a concentrated solution, and recovering the solvent at the same time;

[0056] ④ Add methanol solution containing 10v / v% concentrated sulfuric acid containing 10 times the mass of the concentrated solution to the concentrated solution, reflux and hydrolyze at 70°C for 24 hours, filter the refluxed liquid, and crystallize the filtered liquid at 0°C for 12~72h to obtain Crystals;

[0057] ⑤Filtrate the crystals in step ④, add methanol according to 4.2 times the mass of the crystals, raise the temperature to 70°C until the crystals dissolve, reflux at 70°C for 1 hour, place the refluxed liquid at 0°C, and crystallize for 12~72h;

[0058] ⑥Filtrate the c...

Embodiment 3

[0062] ① pulverize pig brain to obtain pig brain homogenate;

[0063] ②Add extraction solvent to pig brain homogenate, ethanol:chloroform=1~5:1v / v, pig brain homogenate:extraction solvent=1:10w / v, stir and extract at 0~30°C for 6 hours to obtain extract;

[0064] ③ filtering the extract, concentrating the filtered liquid to obtain a concentrated solution, and recovering the solvent at the same time;

[0065] ④ Add methanol solution containing 10v / v% concentrated sulfuric acid containing 10 times the mass of the concentrated solution to the concentrated solution, reflux and hydrolyze at 70°C for 24 hours, filter the refluxed liquid, and crystallize the filtered liquid at 0°C for 12~72h to obtain Crystals;

[0066] ⑤Filtrate the crystals in step ④, add methanol according to 4.2 times the mass of the crystals, raise the temperature to 70°C until the crystals dissolve, reflux at 70°C for 1 hour, place the refluxed liquid at 0°C, and crystallize for 12~72h;

[0067] ⑥Filtrate the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com