Anti-biological-contamination CrN-Ag composite coating and preparation method thereof

A composite coating, biofouling technology, applied in the direction of coating, metal material coating process, ion implantation plating, etc., can solve the problem of limited life extension effect, achieve high hardness, improve anti-biofouling and antibacterial properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

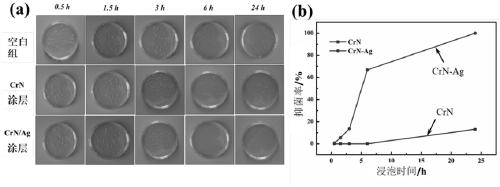

[0025] In this embodiment, the base material is 316 stainless steel. Using magnetron sputtering technology to prepare CrN-Ag composite coating on the surface of the substrate mainly includes the following steps:

[0026] (1) Perform mechanical grinding and polishing on the surface of the substrate, ultrasonically clean it three times with petroleum ether, acetone and alcohol, and then dry it with flowing nitrogen.

[0027] (2) Put the substrate after cleaning into the magnetron sputtering chamber, and evacuate until the vacuum degree is 10 -3 Pa; then, the target was cleaned by sputtering for 2 min, and the substrate sample was ion-etched for 20 min.

[0028] (3) Sputter a Cr target (with a purity of 99.95 at.%) for 10 min, and deposit a Cr transition layer on the surface of the substrate.

[0029] (4) Prepare and deposit CrN-Ag composite coating.

[0030] The cavity is filled with high-purity nitrogen (purity is 99.99at.%), the flow rate is set to 24sccm, using Ag target (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com