Combined pile for foundation engineering

A technology for foundation engineering and combined piles, applied in the field of construction foundation engineering, can solve the problems of eliminating bored piles and difficult to popularize, and achieve the effects of fast construction speed, high bearing capacity, and strong bending and shearing resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

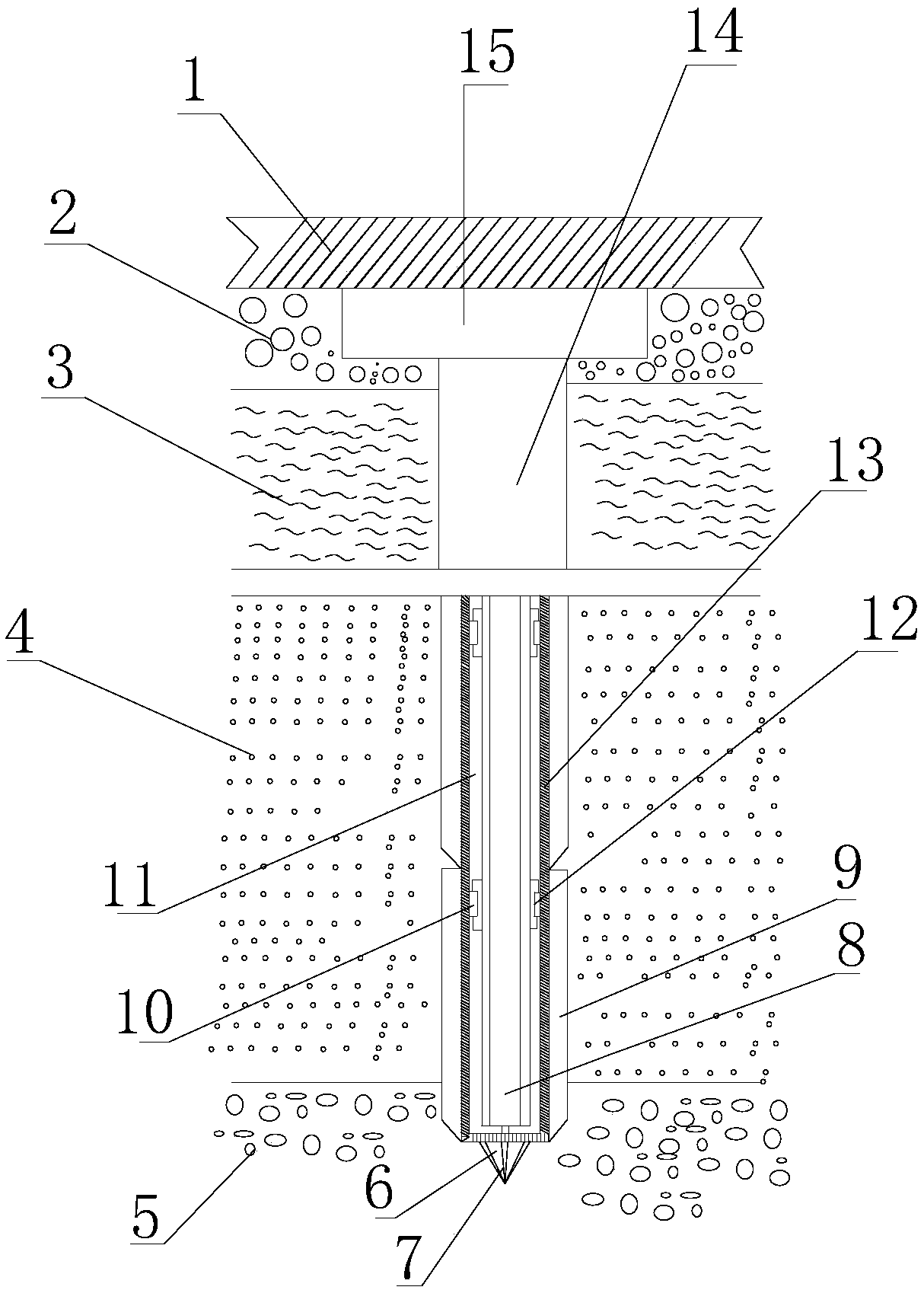

[0015] Such as figure 1 Shown, a kind of composite pile that foundation engineering is used, comprises the first sleeve pipe 8 that is vertically arranged; The periphery of described first sleeve pipe 8 surrounds one deck second sleeve pipe 11, and the A layer of I-shaped steel 13 surrounds the periphery, and the outer layer of the I-shaped steel 13 is poured with cement-soil outer piles 9. A pile tip 6 is arranged at the bottom of the first casing 8, and the top diameter of the pile tip 6 is Smaller than the bottom diameter of the first casing 1, the pile tip 6 is inserted into the gravel layer 5, the cement-soil outer pile 9 is buried in the clay layer 4, and a steel bar is arranged on the mud layer 3 above the first casing 8 Concrete piles 14 are placed, and caps 15 are arranged horizontally on the sand layer 2 above the reinforce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com