Infrared-radiation-preventing heat-insulating device and solar water heater with same

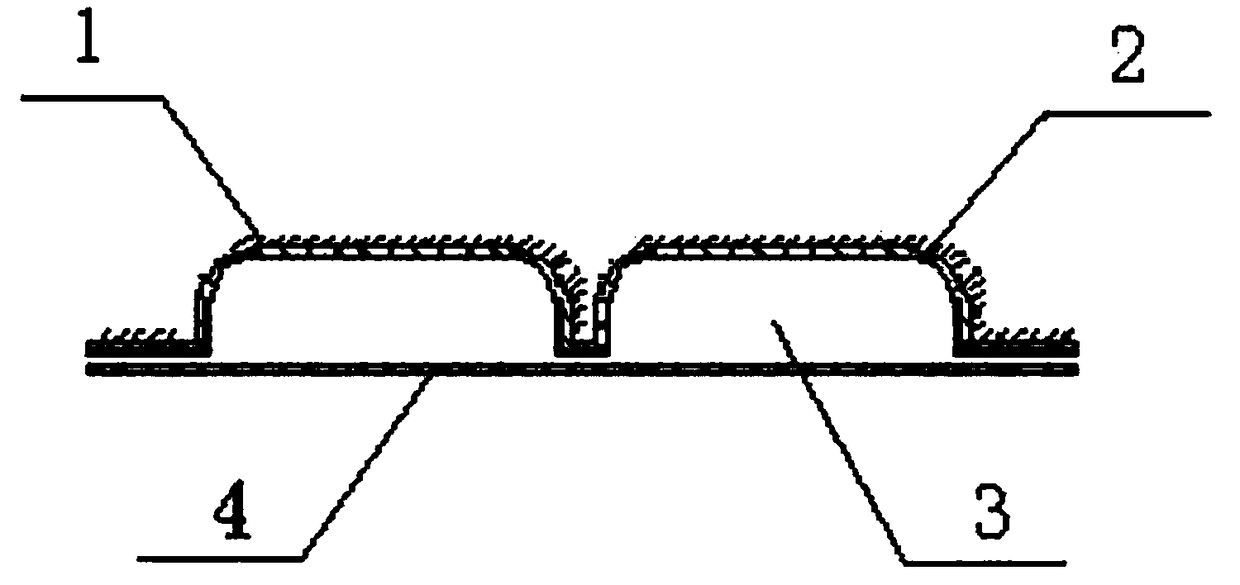

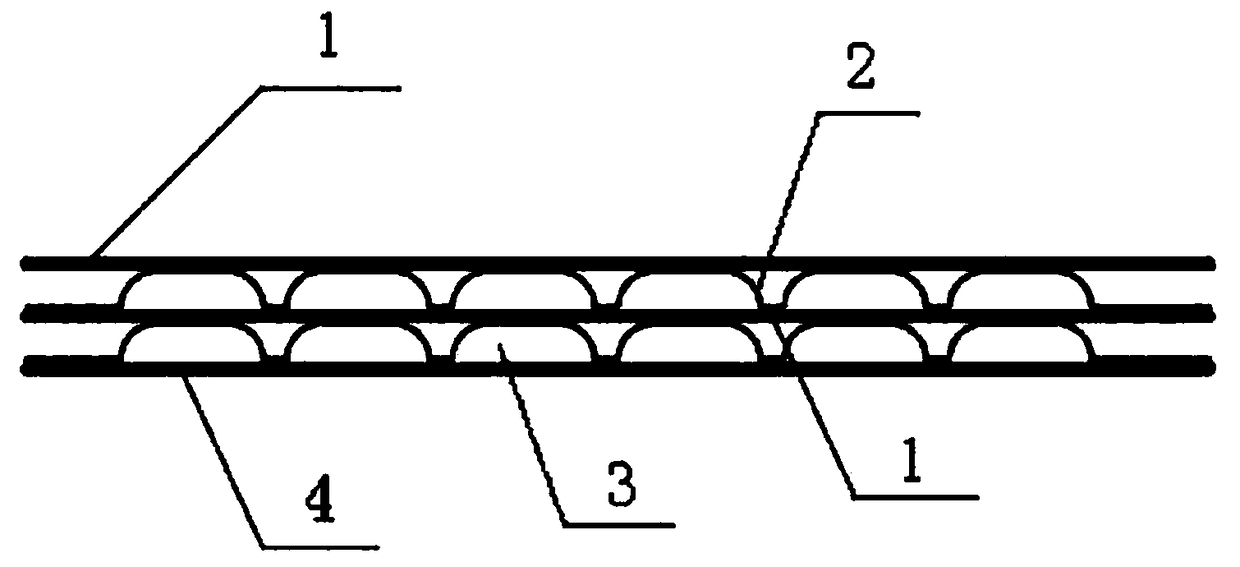

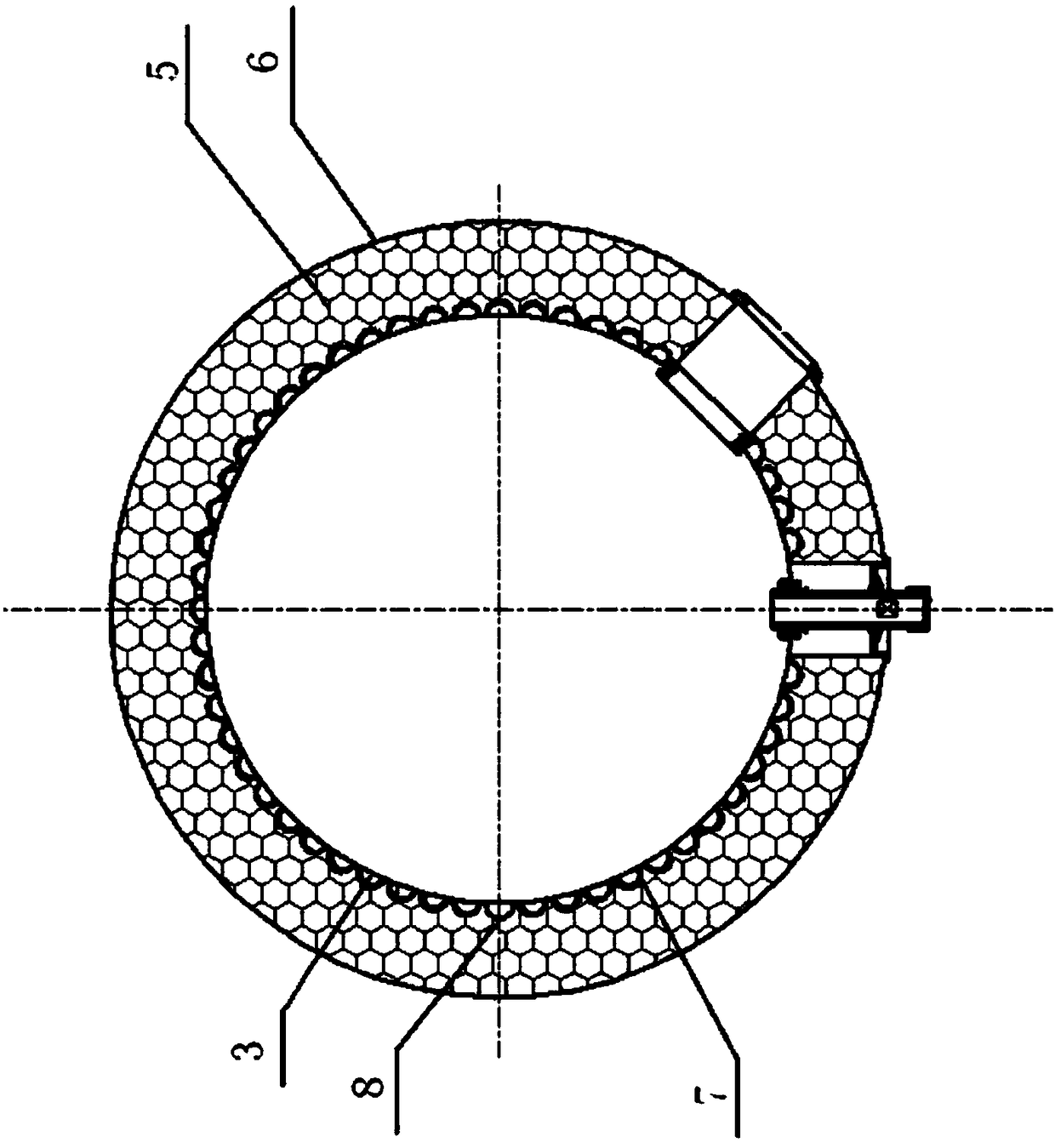

A heat preservation device and anti-infrared technology, which is applied to solar collectors, components of solar collectors, solar thermal energy, etc., can solve the problems of inability to reduce infrared radiation heat dissipation, reduce conduction and heat convection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The following is the preparation process of the anti-infrared polyester fiber of the present invention:

[0040] (1) Disperse the anatase titanium dioxide powder containing 2.5wt.% CuO in absolute ethanol to form a suspension; continuously stir the suspension at 90°C until the ethanol is completely evaporated; then sequentially heat it at 450°C Calcined for 2h and 750℃ for 1h, the doped TiO is obtained after grinding 2 Powder; according to the mass ratio, will be doped with TiO 2 Powder, SnO 2 Powder, WO 3 The powder and NiO powder are ground and mixed by a ball mill, and then the mixed powder, corundum balls, and water are made into a 1:1:6 slurry, and 0.5% sodium lauryl sulfate is added, and grind in a rolling ball mill for 20 hours. Then it is calcined at 310℃~350℃ for 3h. The calcined powder is dispersed, crushed and ground to obtain metal oxide powder; the metal oxide powder is mixed with polyester powder, and the second polyester is obtained by screw granulation Mast...

Embodiment 2

[0045] The following is the preparation process of the polyester fiber of the present invention:

[0046] (1) Disperse the anatase titanium dioxide powder containing 2.5wt.% CuO in absolute ethanol to form a suspension; continuously stir the suspension at 90°C until the ethanol is completely evaporated; then sequentially heat it at 450°C Calcined for 2h and 750℃ for 1h, the doped TiO is obtained after grinding 2 Powder; according to the mass ratio, will be doped with TiO 2 Powder, SnO 2 Powder, WO 3 The powder and NiO powder are ground and mixed by a ball mill, and then the mixed powder, corundum balls, and water are made into a 1:1:6 slurry, and 0.5% sodium lauryl sulfate is added, and grind in a rolling ball mill for 20 hours. Then it is calcined at 310℃~350℃ for 3h. The calcined powder is dispersed, crushed and ground to obtain metal oxide powder; the metal oxide powder is mixed with polyester powder, and the second polyester is obtained by screw granulation Masterbatch

[0047...

Embodiment 3

[0051] The following is the preparation process of the polyester fiber of the present invention:

[0052] (1) Disperse the anatase titanium dioxide powder containing 2.5wt.% CuO in absolute ethanol to form a suspension; continuously stir the suspension at 90°C until the ethanol is completely evaporated; then sequentially heat it at 450°C Calcined for 2h and 750℃ for 1h, the doped TiO is obtained after grinding 2 Powder; according to the mass ratio, will be doped with TiO 2 Powder, SnO 2 Powder, WO 3 The powder and NiO powder are ground and mixed by a ball mill, and then the mixed powder, corundum balls, and water are made into a 1:1:6 slurry, and 0.5% sodium lauryl sulfate is added, and grind in a rolling ball mill for 20 hours. Then it is calcined at 310℃~350℃ for 3h. The calcined powder is dispersed, crushed and ground to obtain metal oxide powder; the metal oxide powder is mixed with polyester powder, and the second polyester is obtained by screw granulation Masterbatch

[0053...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com