On-line ultrasonic nondestructive testing method based on 3D printing

A 3D printing, non-destructive testing technology, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, and measuring devices, etc. Low damage and low price effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

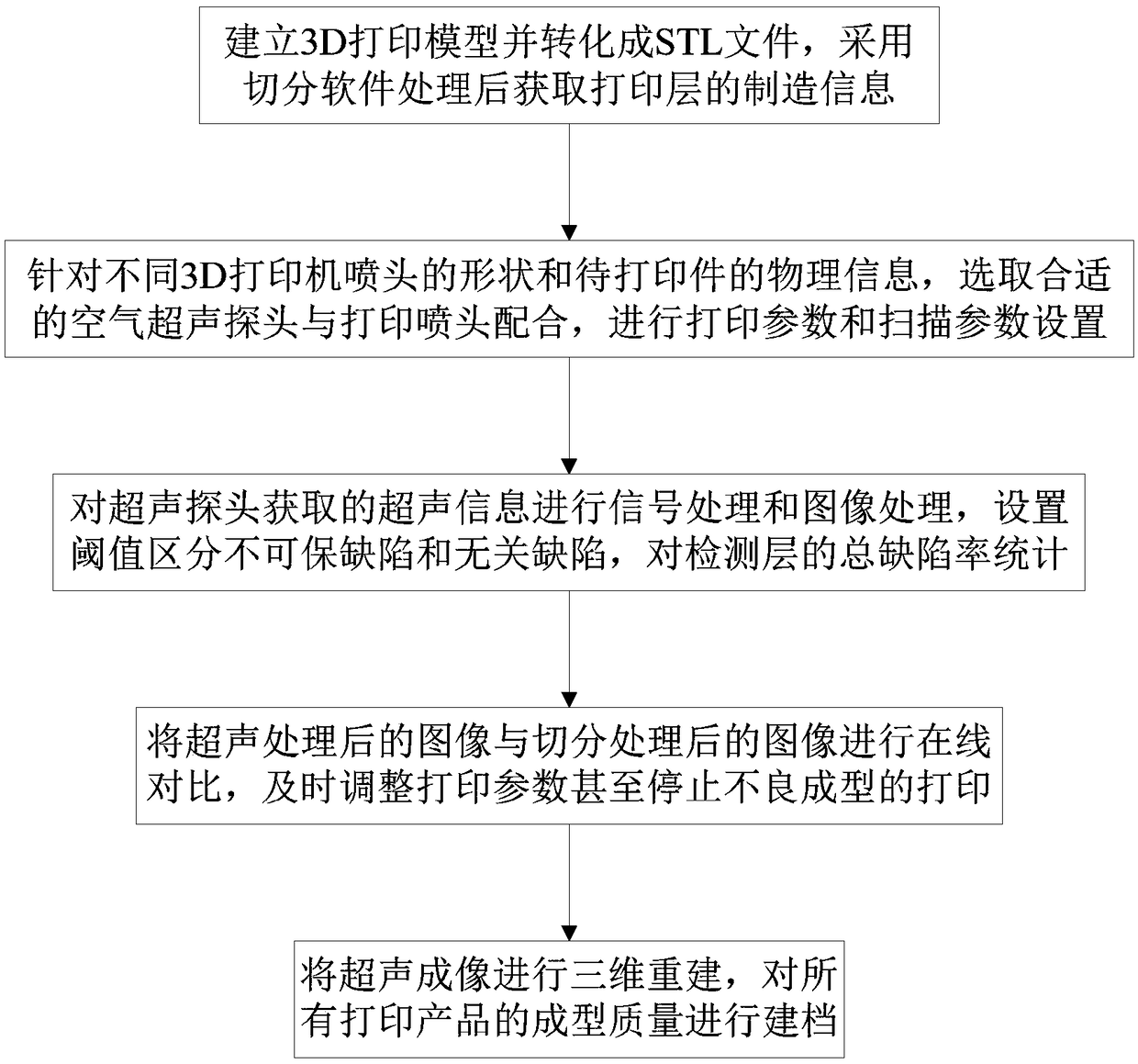

[0028] Such as figure 1 As shown, a kind of online ultrasonic nondestructive testing method based on 3D printing provided by the present invention comprises the following steps:

[0029] 1) Establish a 3D printing model and convert it into an STL file, and obtain the manufacturing information of the printing layer after processing with the cutting software; specifically include:

[0030] Obtain the image to be printed and the printing path of the printing layer after processing by the segmentation software.

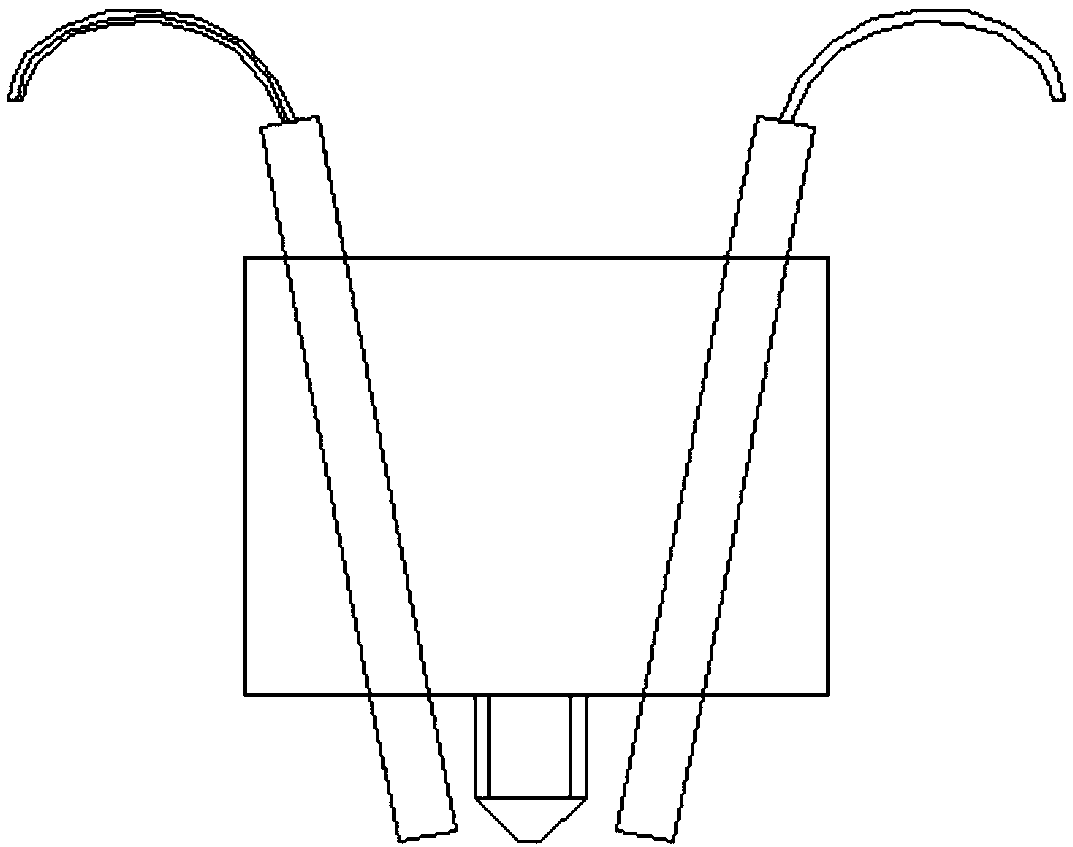

[0031] 2) According to the shape of nozzles of different 3D printers and the physical information (material properties, thickness, etc.) The probe adopts an air-coupled ultrasonic detection probe, and the type of the air-coupled probe is determined according to the nature of the material (such as metal, composite material, plastic, etc.) and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com