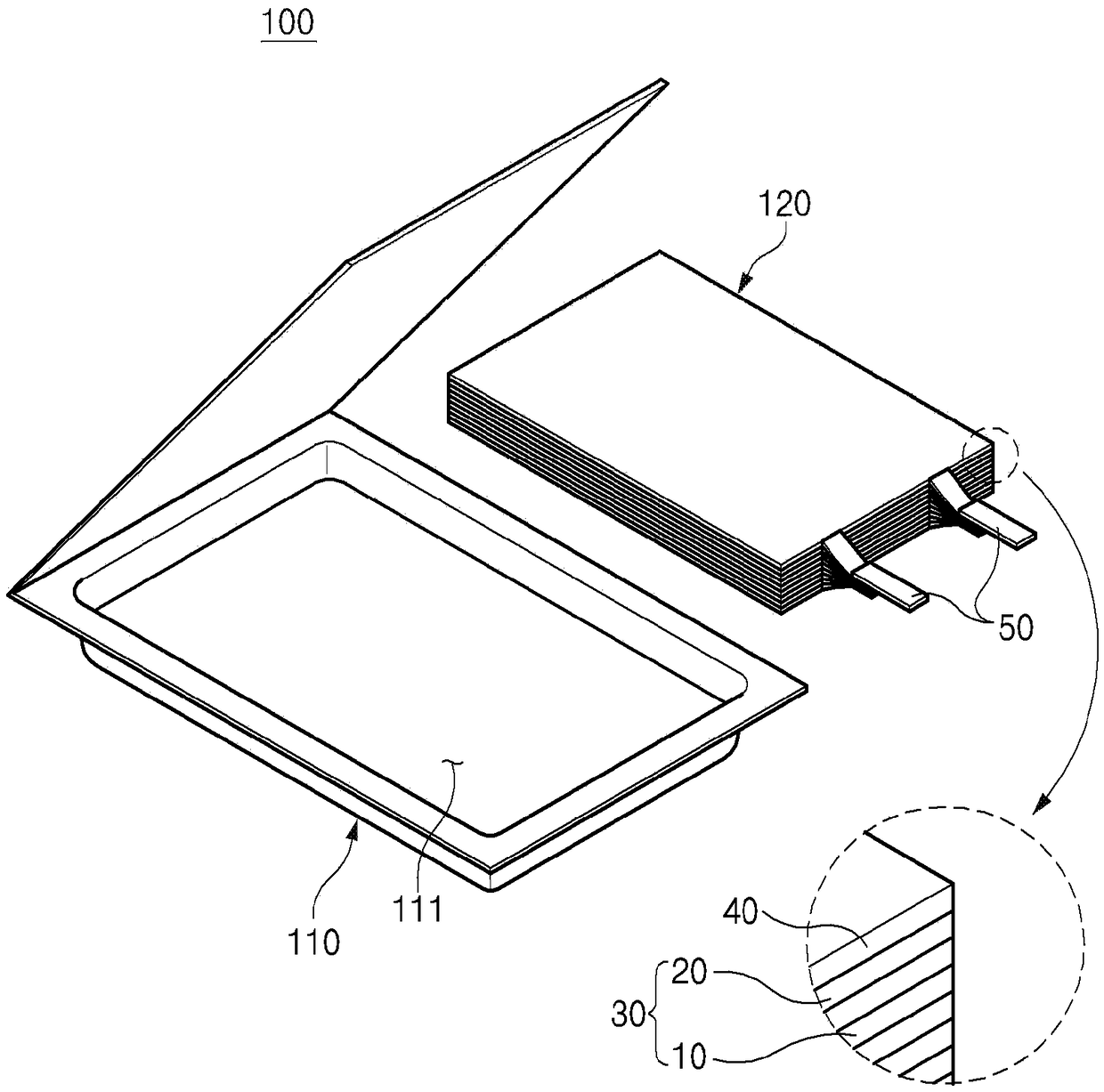

Negative electrode for secondary battery

A secondary battery and negative electrode technology, applied in battery electrodes, negative electrodes, lithium batteries, etc., can solve the problems of deterioration of battery life characteristics, difference in current density, uneven current distribution, etc., and achieve the effect of preventing life shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 10

[0056]

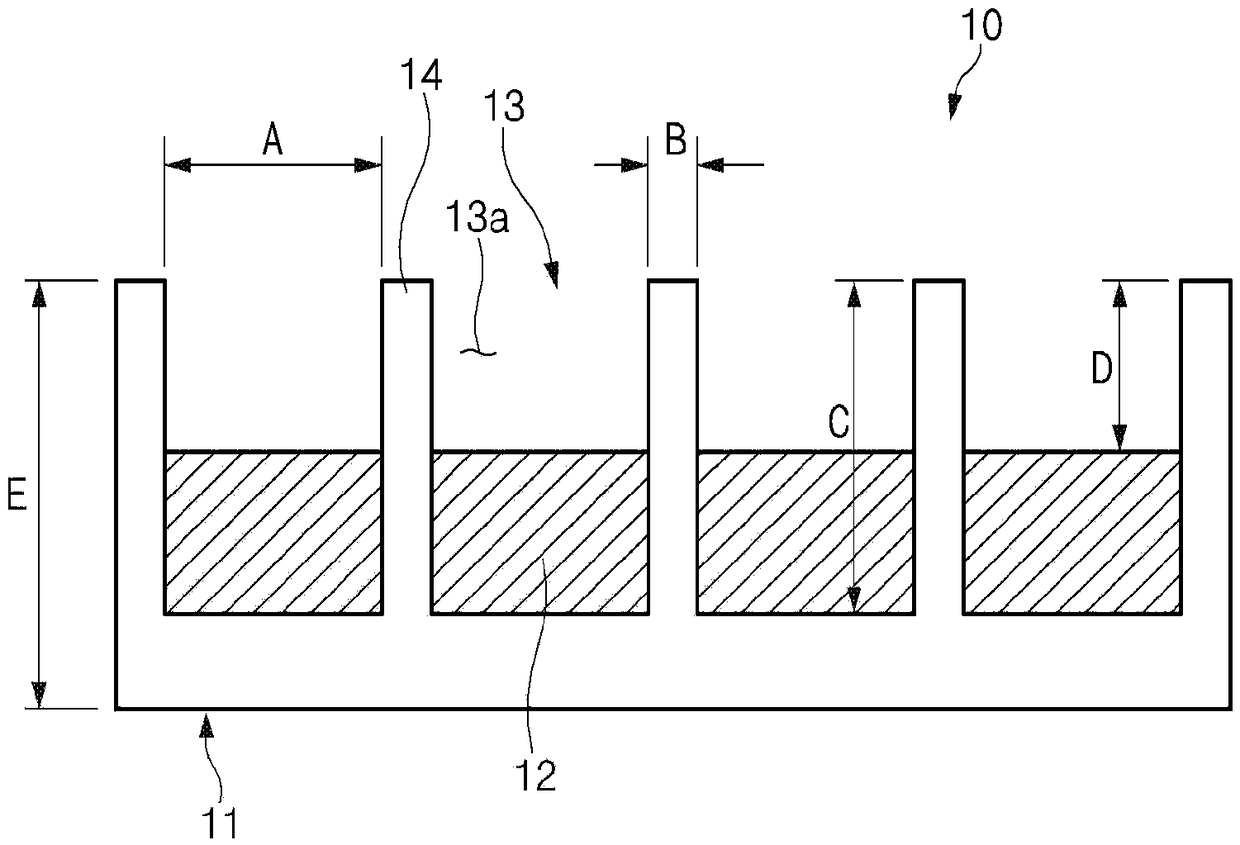

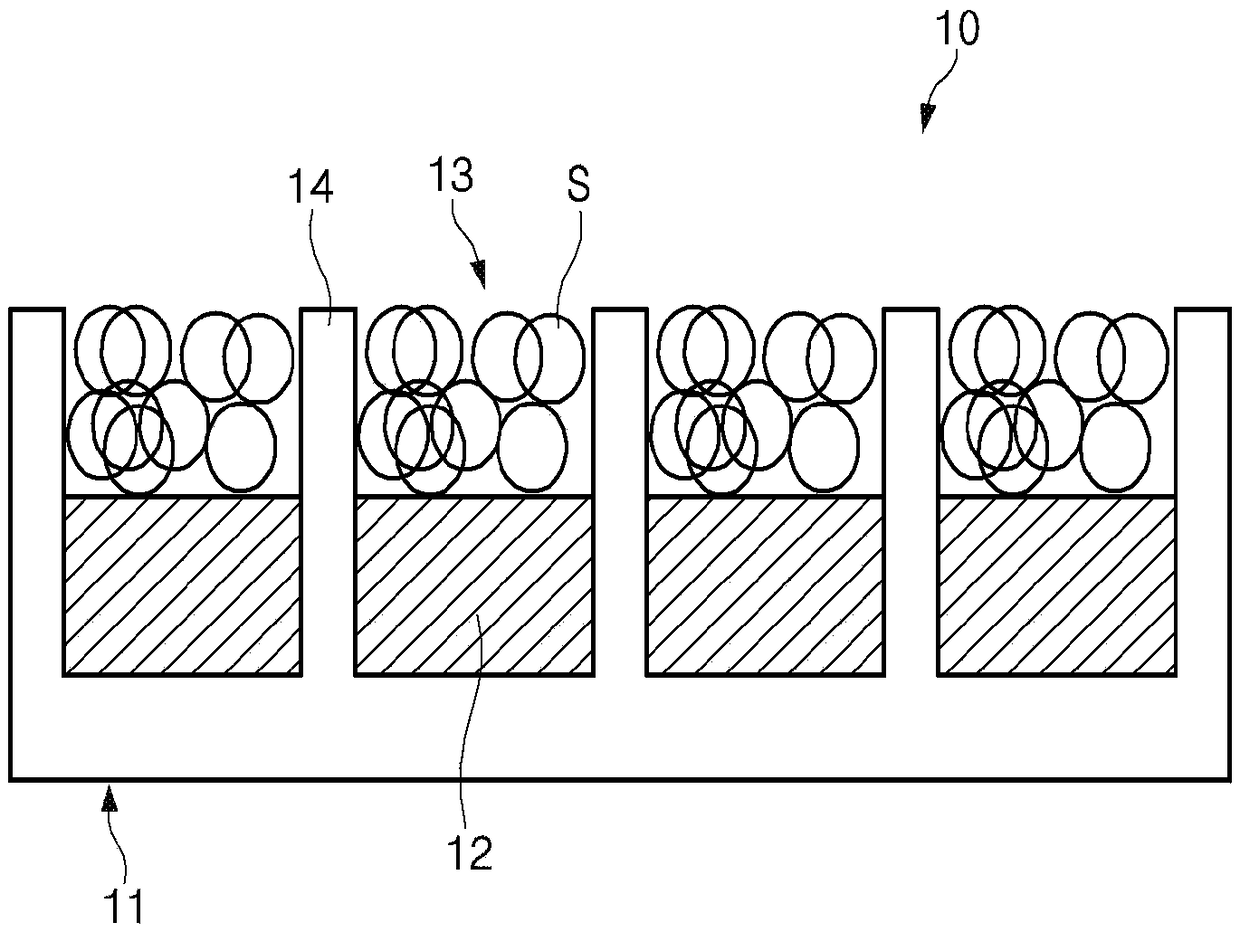

[0057] When the width of the anti-stratification headers 13 is A, the distance between the anti-stratification headers 13 is B, and the depth of the anti-stratification headers 13 is C, it can be constructed under the conditions shown in the table below Lithium secondary battery.

[0058] [Table 1]

[0059]

experiment example

[0061] The apparent capacity and capacity retention rate when the patterns in Table 1 were applied are shown in Table 2 below. In addition, manufactured in which nickel cobalt manganese (NCM) was used as the positive electrode active material, lithium metal was used as the negative electrode active material, PE separator was set as the separator and ethylene carbonate / ethyl methyl carbonate / dimethyl carbonate (EC / EMC / DMC) 1M LiPF6 VC 0.5% by weight as electrolyte cells for evaluation.

[0062] [Table 2]

[0063]

Apparent capacity (mAh)

Capacity retention rate (%), the 200th cycle

Example 1

5.25

88.57

Example 2

5.24

86.65

Example 3

5.26

84.15

Example 4

5.28

86.57

Example 5

5.28

70.57

Example 6

5.28

76.57

Example 7

5.28

56.57

Example 8

5.28

46.57

Example 9

5.29

35.78

Example 10

5.21

25.23

Comparative example 1

5.24

20.4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com