Ability to reduce co and no x Emitted composition, method for its preparation and use, and fluid catalytic cracking method

A fluidized catalytic cracking, catalytic cracking technology, applied in catalytic cracking, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problem of low catalytic conversion activity, and achieve catalytic conversion activity. High, lower CO and NOx emissions, lower usage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

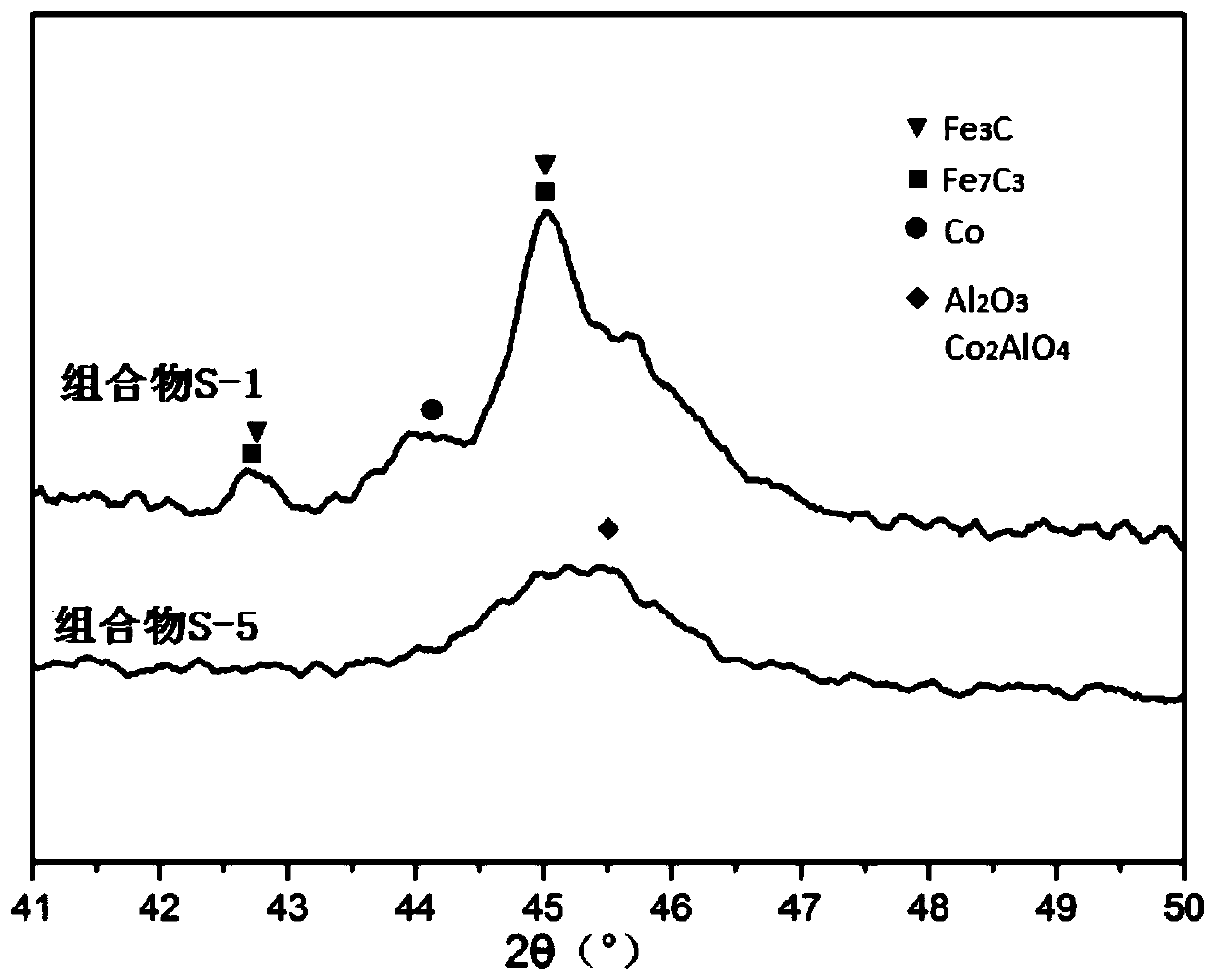

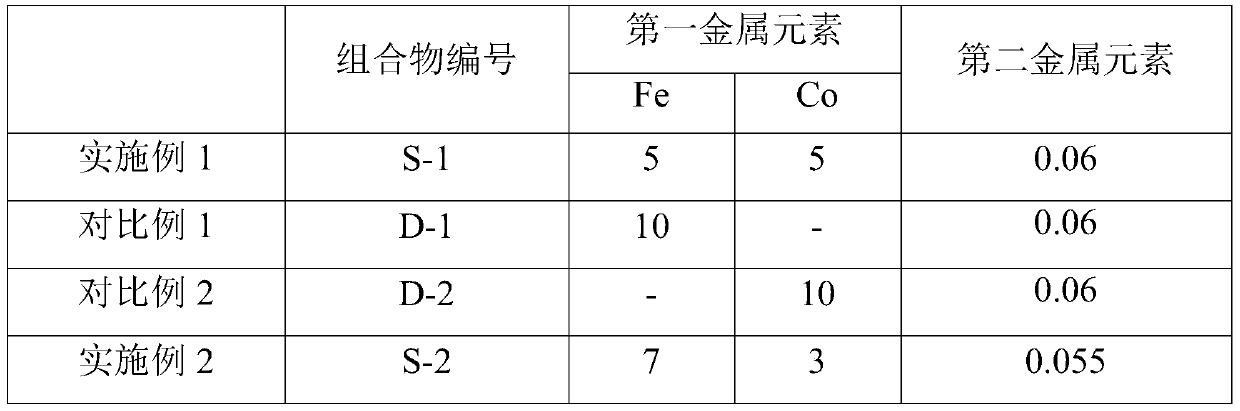

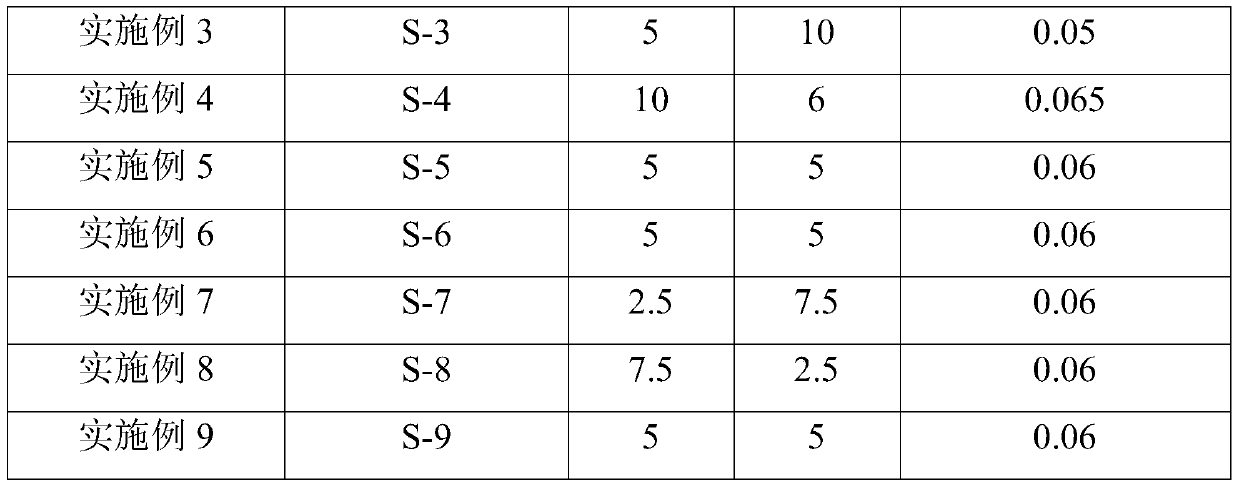

[0035] According to a most preferred embodiment of the present invention, the composition is composed of an inorganic oxide carrier and a first metal element and a second metal element supported on the inorganic oxide carrier, and the first metal element is only Fe and Co.

[0036] In the present invention, as long as Fe and Co are contained in the first metal element, the composition to NH 3 The catalytic conversion activity of reduction state nitrides, etc., in order to further bring into play the synergistic effect of Fe and Co, preferably, in terms of oxides, the weight ratio of Fe and Co is 1:(0.1-10), more preferably 1:( 0.3-3), more preferably 1: (0.4-2). The inventors of the present invention found that a specific ratio of Fe and Co can produce a better synergistic effect, which is more conducive to improving the performance of the composition.

[0037] In the present invention, unless otherwise specified, Fe in terms of oxides refers to Fe in terms of Fe 2 o 3 In ...

specific Embodiment approach

[0053] According to a specific embodiment of the present invention, the composition includes: alumina and Fe, Co and Ru supported on alumina, in terms of oxides, the weight ratio of Fe to Co is 1: (0.4-2), Based on the total amount of the composition, the content of aluminum oxide is 83.93-89.95% by weight, the total content of Fe and Co is 10-16% by weight, and the content of Ru is 0.05-0.07% by weight.

[0054] Among the present invention, each component content in the composition that can reduce CO and NOx discharge all adopts X-ray fluorescence spectroscopic analysis method (petrochemical analysis method (RIPP experimental method), edited by Yang Cuiding, etc., published by Science Press in 1990) .

[0055] The present invention also provides a method for preparing a composition capable of reducing CO and NOx emissions, the method comprising:

[0056](1) mixing and beating the precursor of the inorganic oxide carrier, the precursor of the first metal element and water to ...

Embodiment 1

[0108] (1) 2.62kg of pseudo-boehmite is added to 14.2kg of deionized water for beating and dispersion, then 238mL of hydrochloric acid is added for acidification for 15min to obtain the bauxite colloid, and ferric nitrate (calculated as Fe) 2 o 3 meter, the same below) 100g, cobalt nitrate (in Co 2 o 3 Add 100g of bauxite colloid, the same below) into 3500mL of water and stir until it is fully dissolved, then add bauxite colloid and stir for 20min to obtain a slurry, spray dry the slurry, and take 150g of spray-dried particles (average particle diameter is 65μm, particle particles with a diameter of 40-80 μm accounted for 60%, the same below) were transferred to the tube furnace, and CO / N with a CO concentration of 10% by volume was fed at a flow rate of 100mL / min. 2 Mixed gas, treated at 600°C for 1.5h to obtain a semi-finished composition;

[0109] (2) Weigh 100g of the above semi-finished composition and add it to 700mL of water, then add RuCl with a mass content of 12.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com