Eight-head circular mould numerical control gun drill machine tool

A technology of gun drilling and machine tools, which is applied in the field of eight-head ring mold CNC gun drilling machine tools, can solve the problems of complex processing and low efficiency of four-head gun drilling, and achieve the effects of improved efficiency, simple operation, and high adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

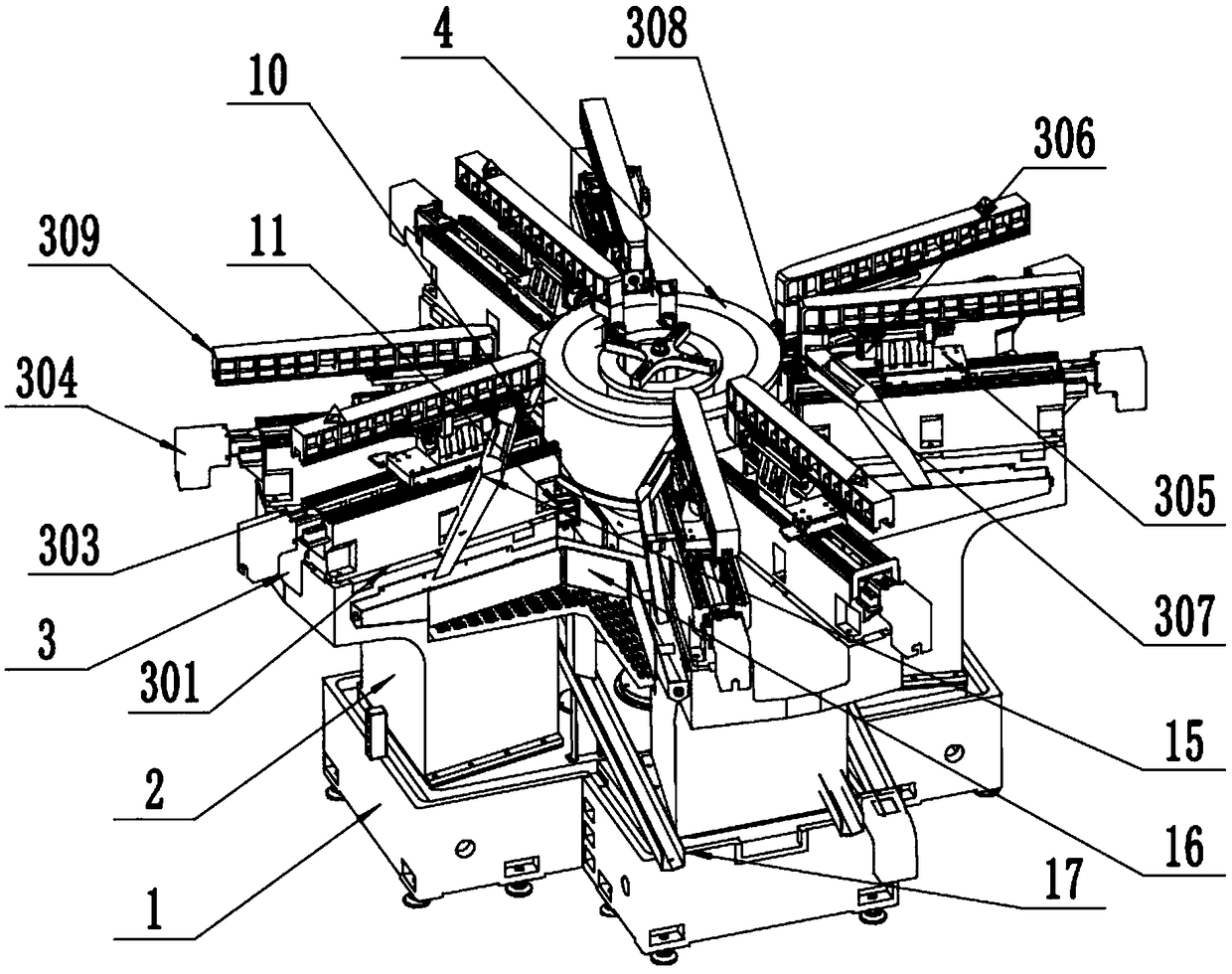

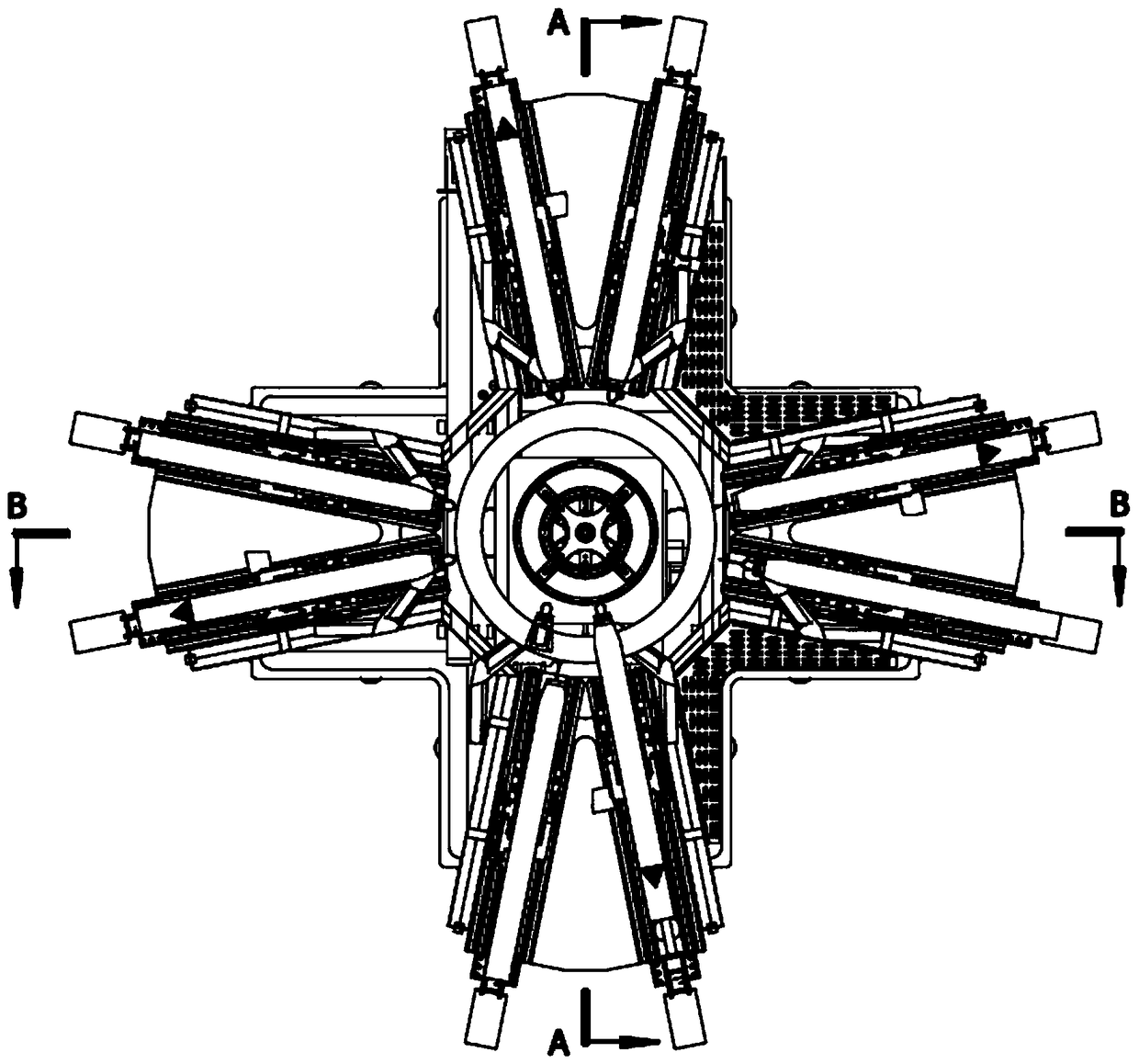

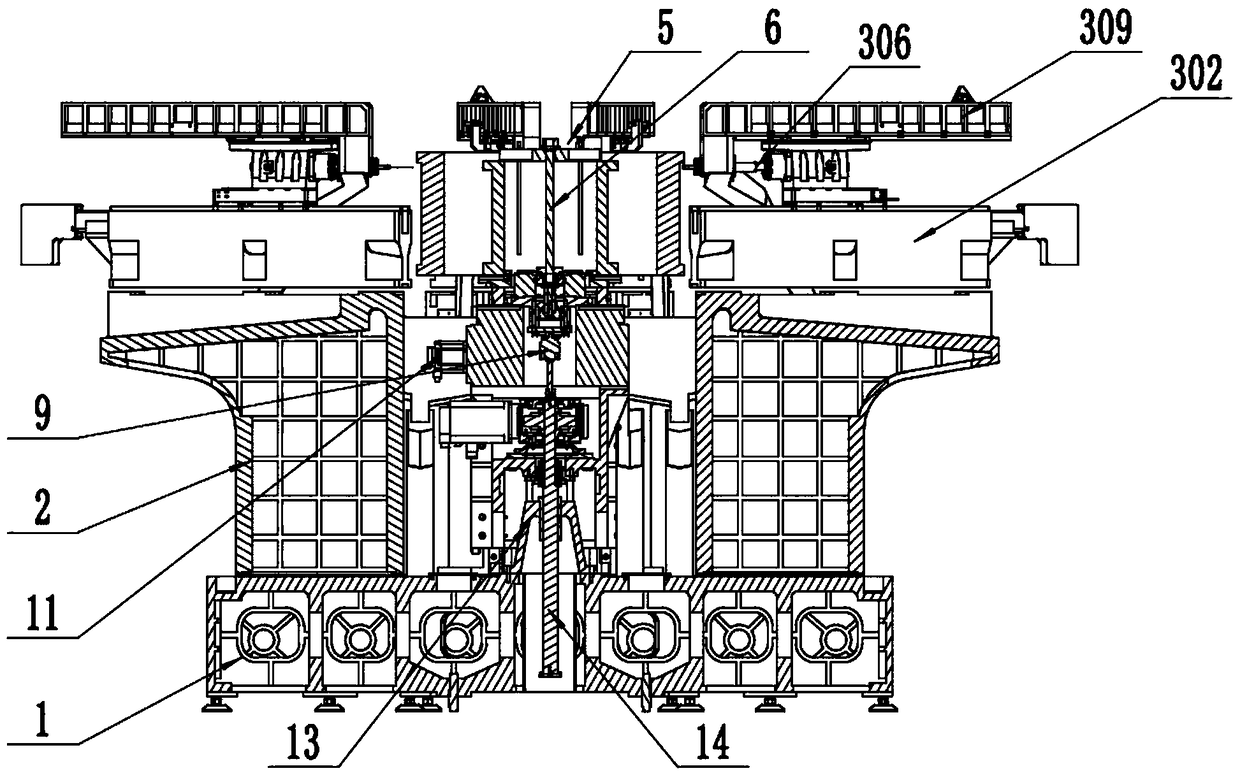

[0030] Such as Figure 1-4 As shown, this embodiment provides an eight-head ring mold CNC gun drilling machine tool, which mainly includes a base 1, a column 2, a gun drill 3 and a clamping device. The bottom of the machine tool is the base 1, and the clamping device is vertically arranged on the base 1 In the middle of the base 1, a cube column 2 is vertically installed in four directions of the base 1, and the shape of the base 1 is a "ten" shape, and the four columns 2 in the four directions are arranged symmetrically along the center of the center, such as figure 2 As shown, two gun drills 3 are installed above the column 2, and the two gun drills 3 are distributed radially along the clamping device horizontally, and two adjacent gun drills 3 on the same column 2 are arranged radially and The included angle is 22.5 degrees, and the drill bits of eight gun drills 3 on the four columns 2 all point to the center of circle of the central ring die 4 workpieces.

[0031] Such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com