A kind of release agent graphic film and its preparation method and application

A release agent and graphics technology, applied in chemical instruments and methods, synthetic resin layered products, coatings, etc., can solve the problems of inability to coat complex curved surface structures, high cost, low precision, etc., to avoid easy damage to the screen , high degree of coating freedom, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

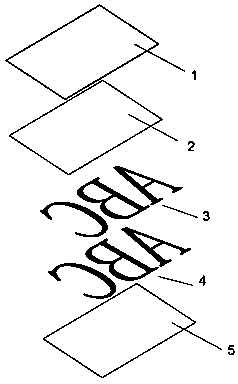

[0048] Use the release agent graphic film to make the release agent graphic on the flat metal plate, the steps are as follows:

[0049] 1. Choose PVC film, the thickness is 0.1mm (good hand feeling, good softness), the length × width is 400 × 400mm;

[0050] 2. Use automatic printing method to print the silicone oil resin on the PVC film to form a layer of release film, and wait for it to dry completely;

[0051] 3. Start the printing machine, print the water-soluble resin on the surface of the release film to form a water-soluble resin carrier, and wait for it to dry completely;

[0052] 4. Print the graphics on the water-soluble resin with a release agent;

[0053] 5. Apply the peeling film (size: 400×400mm) on the water-soluble resin carrier printed with the release agent pattern to obtain the release agent pattern coating;

[0054] 6. Cut out flat substrates by wire cutting or high pressure water cutting;

[0055] 7. Alkaline collapse and pickling on the surface of the ...

Embodiment 2

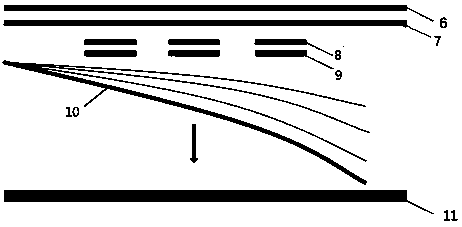

[0059] Use release agent graphics coating to make release agent graphics on curved metal parts, the steps are as follows:

[0060] 1. Choose PVC film, the thickness is 0.1mm (good hand feeling, good softness), the length × width is 400 × 400mm;

[0061] 2. Use digital and analog processing software to expand the curved surface to be printed into a plane size;

[0062] 3. Use automatic printing method to print the silicone oil resin on the PVC film to form a layer of release film, and wait for it to dry completely;

[0063] 4. Input the unfolded plane graphics into the automatic printing equipment, start the printing machine, print the water-soluble resin on the surface of the release film to form a water-soluble resin carrier, and wait for it to dry completely;

[0064] 5. Print the graphics on the water-soluble resin with a release agent and wait for it to dry completely;

[0065] 6. Apply the release film (size: 400×400mm) on the water-soluble resin carrier printed with th...

Embodiment 3

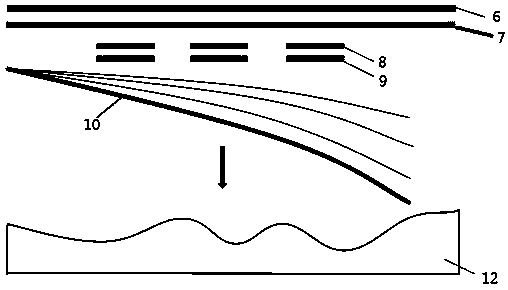

[0072] Use the release agent pattern coating to make the release agent pattern on the inner wall of the cylinder, the steps are as follows:

[0073] 1. Choose PVC film, the thickness is 0.1mm (good hand feeling, good softness), the length × width is 400 × 400mm;

[0074] 2. Use digital and analog processing software to expand the curved surface to be printed into a plane size;

[0075] 3. Use automatic printing method to print the silicone oil resin on the PVC film to form a layer of release film, and wait for it to dry completely;

[0076] 4. Input the unfolded plane graphics into the automatic printing equipment, start the printing machine, print the water-soluble resin on the release film, and wait for it to dry completely;

[0077] 5. Print the graphics on the water-soluble resin with a release agent;

[0078] 6. Apply the release film (size: 400×400mm) on the water-soluble resin carrier printed with the release agent pattern to obtain the release agent pattern coating; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com