Device and method for recycling sludge after sewage treatment

A sludge circulation and sewage treatment technology, applied in biological sludge treatment, fertilization equipment, invertebrate treatment, etc., can solve the problems of secondary pollution of the atmosphere, high operating costs, large floor space, etc., and achieve the elimination of germs , increase the heating area, accelerate the effect of falling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

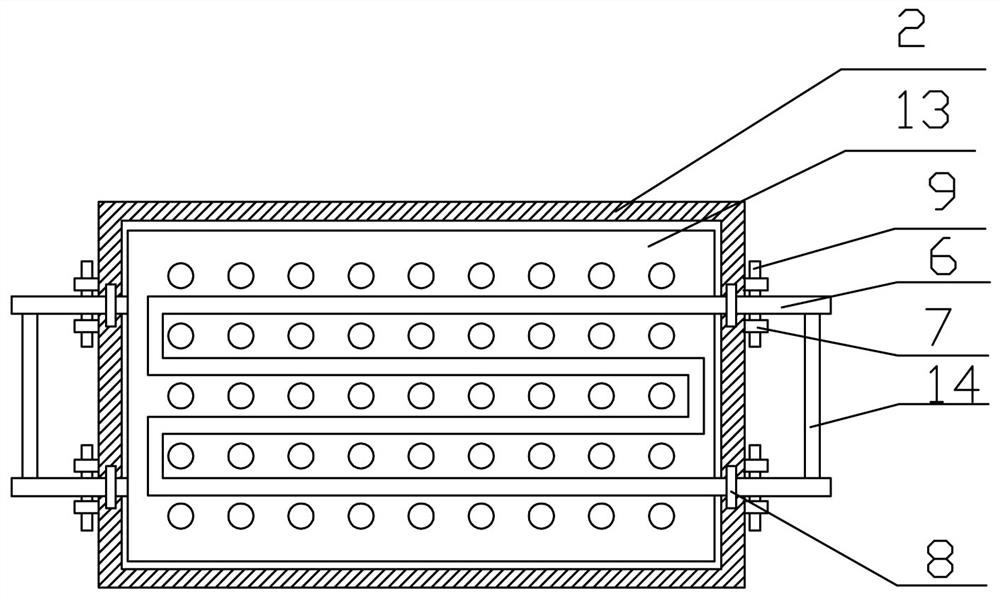

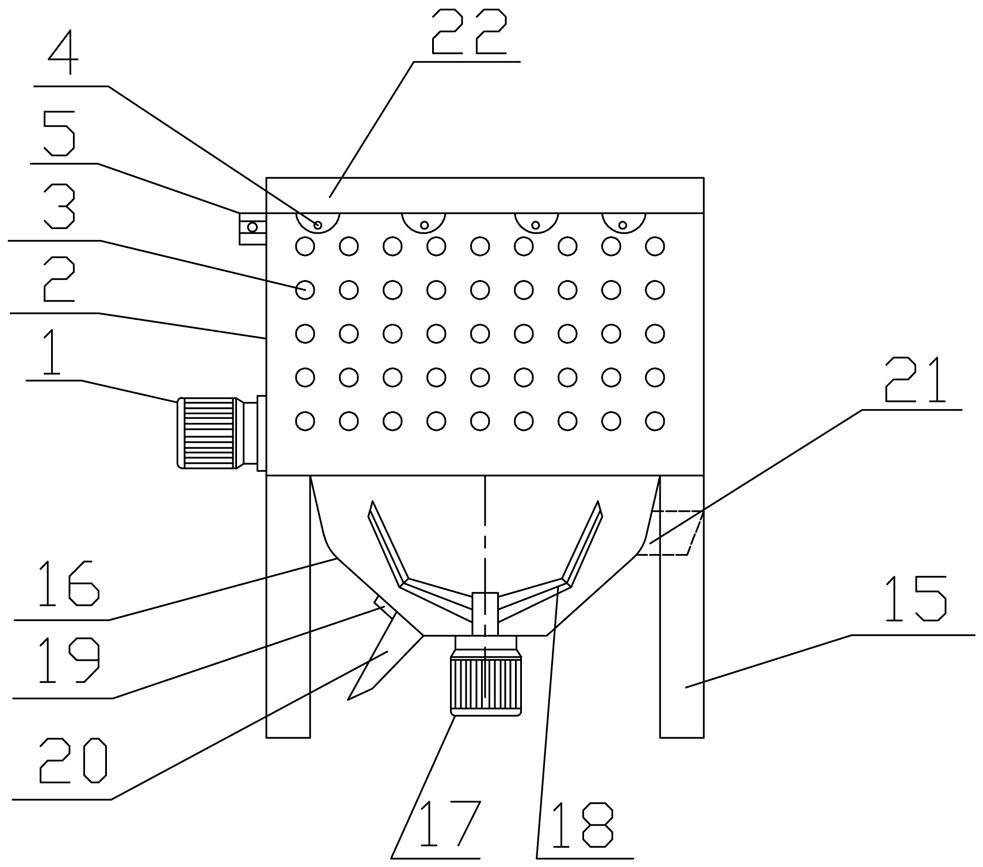

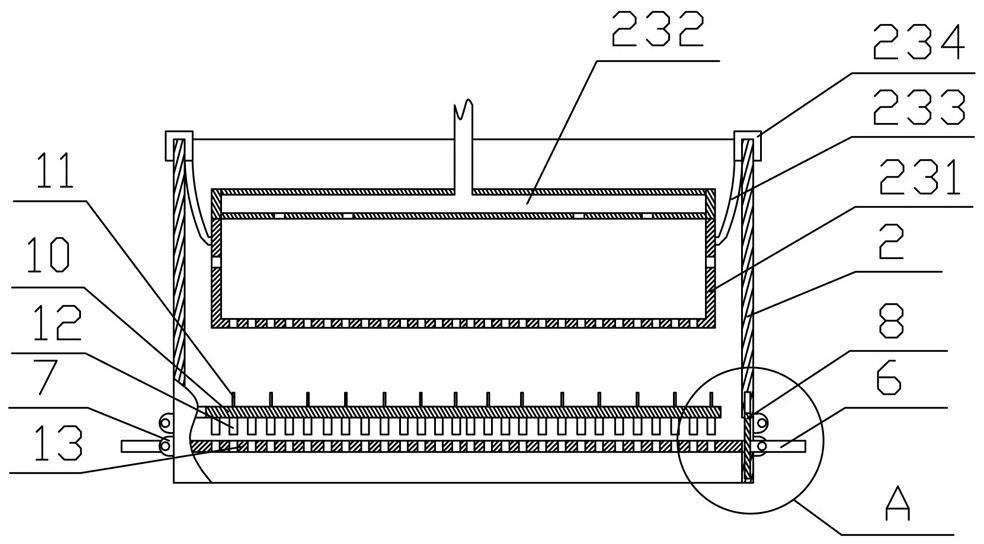

[0037] Such as Figure 1 to Figure 7 As shown, a device for recycling sludge after sewage treatment includes a support frame 15 and an earthworm breeding bin fixed above the support frame 15. The earthworm breeding bin includes a bin body 2, a bin cover 22, a lighting assembly and a discharge Assemblies, ventilation holes 3 are evenly arranged on the sides of the warehouse body 2, and the warehouse cover 22 is covered to the top of the warehouse body 2 to provide a cool environment, which is suitable for the growth of earthworms; the lighting assembly includes a light source 4 and a light source for powering the light source 4 A controller 5, the light source 4 is fixed to the upper side of the side wall of the bin body 2;

[0038]The discharge assembly includes a metal screen 10, a vibrating motor 1 for driving the metal screen 10 to swing (the vibrating motor 1 drives the metal screen 10 to swing using the existing technology) and a discharge bottom plate 13. A gap of 10 cm...

Embodiment 2

[0041] It is basically the same as Embodiment 1, except that the two moving rods 6 on one side of the discharge bottom plate 13 are connected by a connecting rod 14 . The light source 4 is a cold light source without temperature, and the intensity of the light source 4 is adjusted by the light source controller 5 . The bin body 2 is made of light-shielding material. Described stirring paddle 18 comprises four uniformly arranged blades, and described blade comprises first segment blade 181 and second segment blade 182, and one end of described first segment blade 181 is connected to the shaft of stirring paddle 18, and the other end is connected to The second section of blade 182, the first section of blade 181 is 25 degrees to the horizontal plane, the distance between the second section of blade 182 and the first section of blade 181 is 130 degrees, and the cross sections of the first section of blade 181 and the second section of blade 182 are diamond-shaped . The height o...

Embodiment 3

[0043] According to implementation 1, a method for treating sludge with a device for recycling sludge after sewage treatment includes the following steps: placing the device in a dark environment when in use;

[0044] Step 1: Preparatory work: Position the moving rod 6 to the upper end of the waist-shaped hole on the side wall of the bin body 2, insert the cylinder 12 into the round hole of the discharge bottom plate 13, and at this time, the bottom of the bin body 2 is sealed;

[0045] Step 2: Add sludge after sewage treatment into the bin body 2, and then add earthworms, the amount of earthworms added is 10g of earthworms per kilogram of sludge, cover the bin cover 22, turn on the light source 4, and use the light source controller 5 Adjust the intensity of the light source 4, and the earthworms enter the sludge to process the sludge, and the treatment time is 15 days;

[0046] Step 3: Turn off the light source 4, pass steam into the discharge bottom plate 13 to heat the dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com