Efficient anti-blocking type three-stage septic-tank

A septic tank, a three-stage technology, applied in the direction of chemical instruments and methods, special treatment targets, biological sludge treatment, etc., can solve the problem that microorganisms cannot decompose the solidified matter, affect the quality and efficiency of septic, and the sludge mixture with large viscosity and other problems to achieve the effect of compact structure, simple structure and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

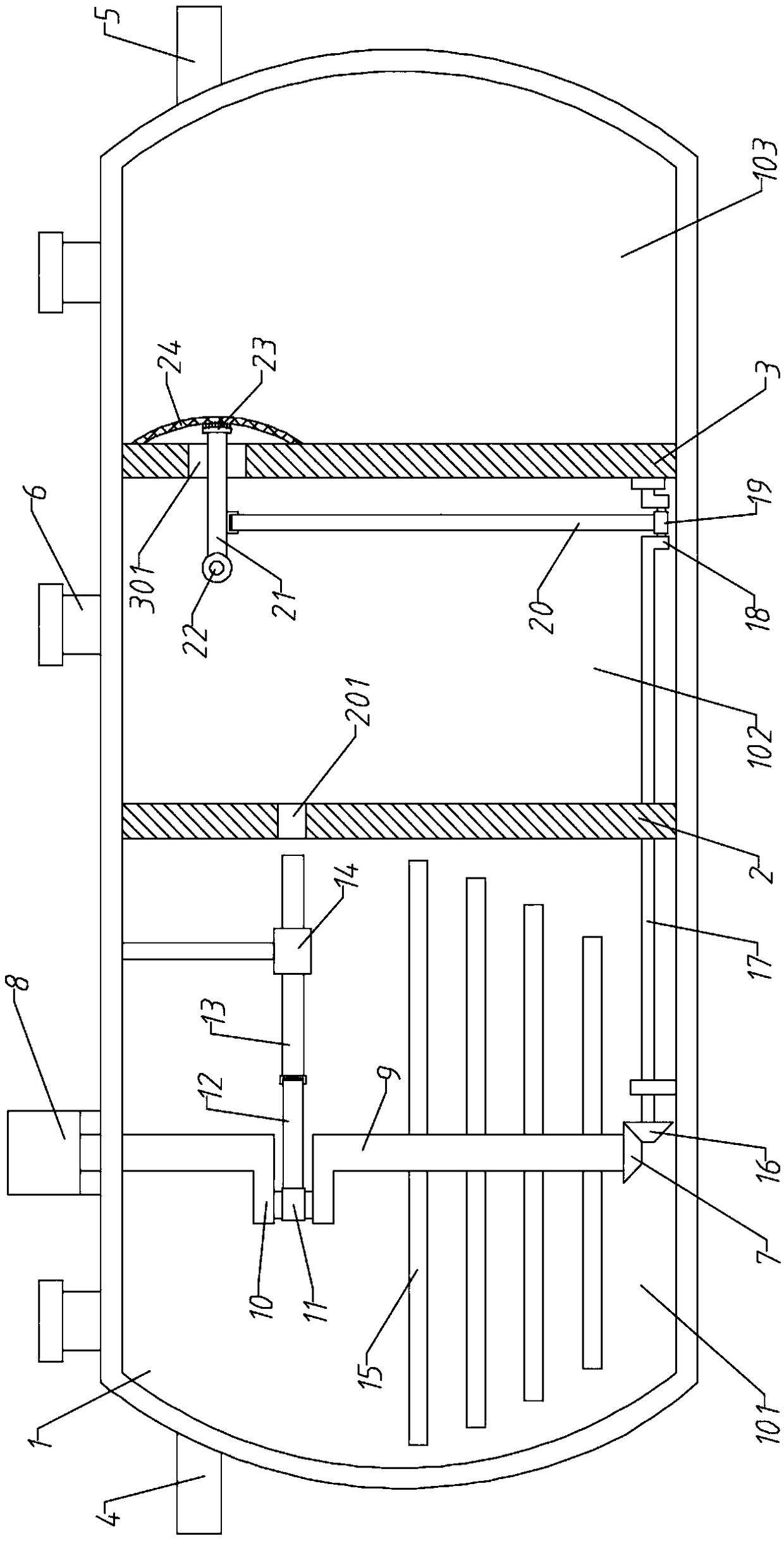

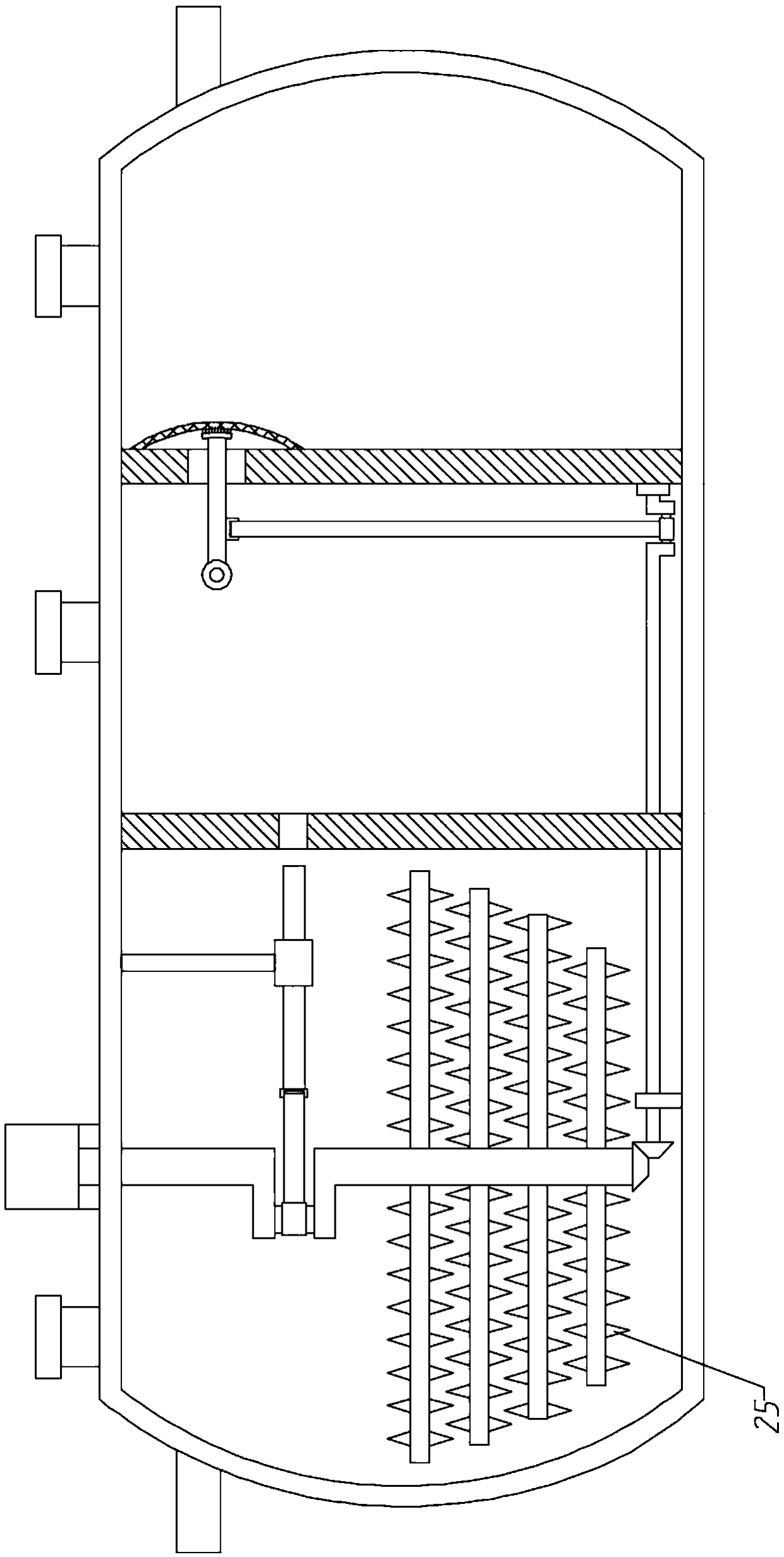

[0037] A high-efficiency anti-blocking three-stage septic tank, including a septic tank body 1, a No. 1 partition 2 and a No. 2 partition 3 are fixedly connected to the interior of the septic tank body 1, and the septic tank body 1 is arranged from left to The right is divided into a primary pool 101, a secondary pool 102 and a tertiary pool 103;

[0038] The upper part of the No. 1 partition 2 is provided with a primary diversion port 201, and the upper part of the No. 2 partition 3 is provided with a secondary diversion port 301, and the level of the secondary diversion port 301 is higher than that of the primary diversion port 201; A screen cover 24 is installed on the right side of the No. 2 partition 3 corresponding to the secondary diversion port 301;

[0039] A driving motor 8 is installed on the top of the first-level pool 101, and the driving motor 8 is connected with a No. 1 shaft 9 downward, and the No. 1 shaft 9 extends into the first-level pool 101; The crutch 10...

Embodiment 2

[0048] A high-efficiency anti-blocking three-stage septic tank, including a septic tank body 1, a No. 1 partition 2 and a No. 2 partition 3 are fixedly connected to the interior of the septic tank body 1, and the septic tank body 1 is arranged from left to The right is divided into a primary pool 101, a secondary pool 102 and a tertiary pool 103;

[0049] The upper part of the No. 1 partition 2 is provided with a primary diversion port 201, and the upper part of the No. 2 partition 3 is provided with a secondary diversion port 301, and the level of the secondary diversion port 301 is higher than that of the primary diversion port 201; A screen cover 24 is installed on the right side of the No. 2 partition 3 corresponding to the secondary diversion port 301;

[0050] A driving motor 8 is installed on the top of the first-level pool 101, and the driving motor 8 is connected with a No. 1 shaft 9 downward, and the No. 1 shaft 9 extends into the first-level pool 101; The crutch 10...

Embodiment 3

[0059] A high-efficiency anti-blocking three-stage septic tank, including a septic tank body 1, a No. 1 partition 2 and a No. 2 partition 3 are fixedly connected to the interior of the septic tank body 1, and the septic tank body 1 is arranged from left to The right is divided into a primary pool 101, a secondary pool 102 and a tertiary pool 103;

[0060] The upper part of the No. 1 partition 2 is provided with a primary diversion port 201, and the upper part of the No. 2 partition 3 is provided with a secondary diversion port 301, and the level of the secondary diversion port 301 is higher than that of the primary diversion port 201; A screen cover 24 is installed on the right side of the No. 2 partition 3 corresponding to the secondary diversion port 301;

[0061] A driving motor 8 is installed on the top of the first-level pool 101, and the driving motor 8 is connected with a No. 1 shaft 9 downward, and the No. 1 shaft 9 extends into the first-level pool 101; The crutch 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com