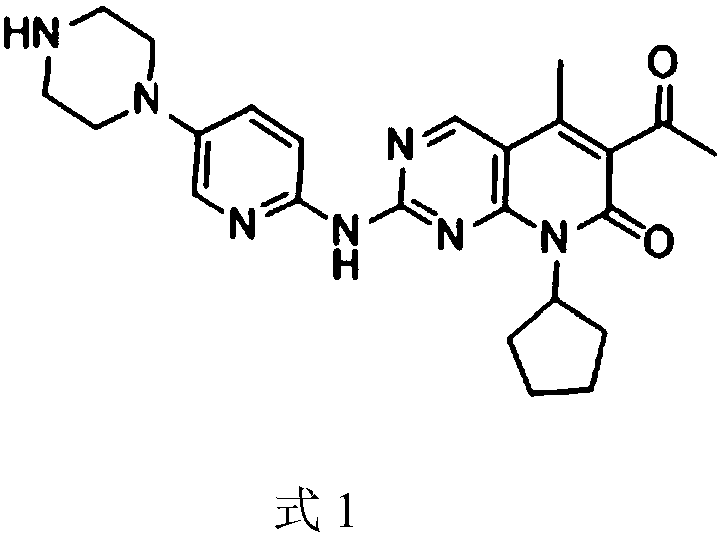

Preparation process of palbociclib intermediate 5-bromo-2-chloro-4-cyclopentyl aminopyrimidine

A cyclopentylaminopyrimidine, a preparation technology, applied in the field of pharmaceuticals, to achieve the effect of improving the production technology, great significance, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

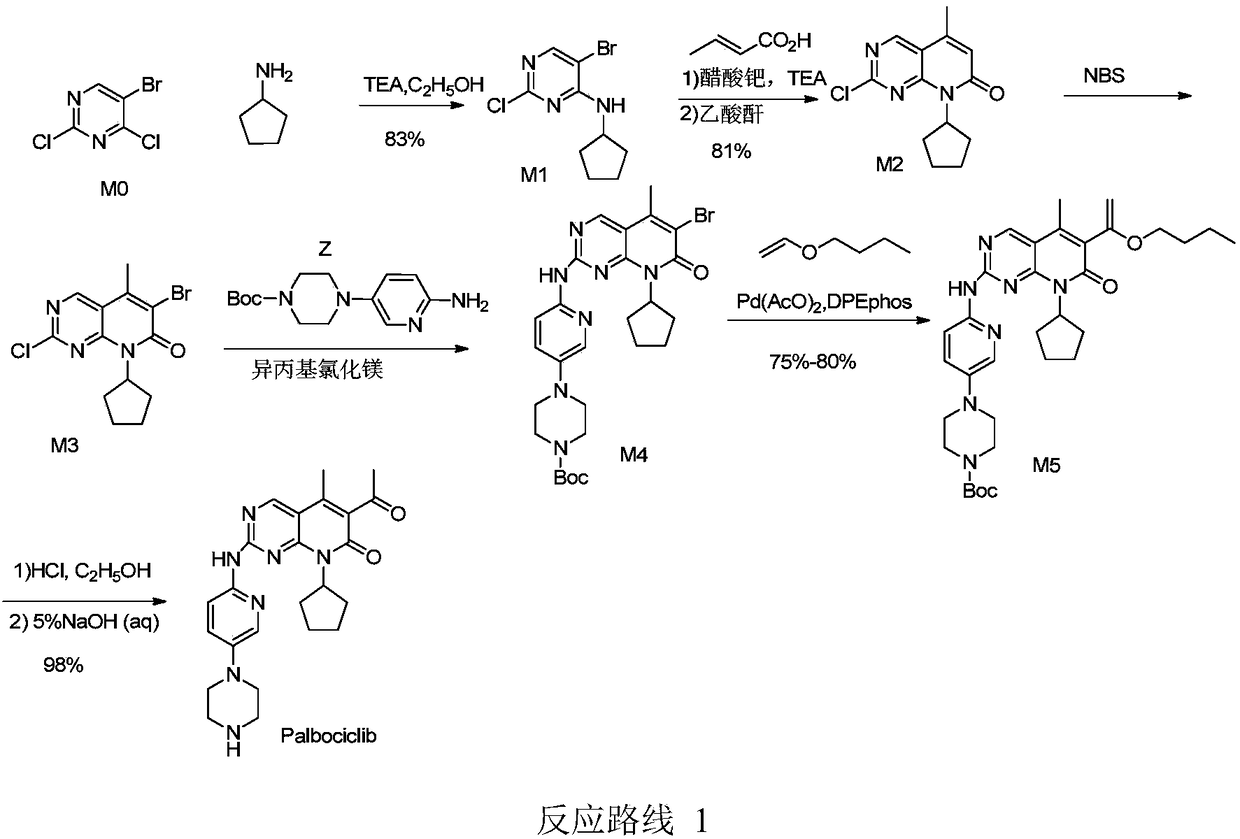

Method used

Image

Examples

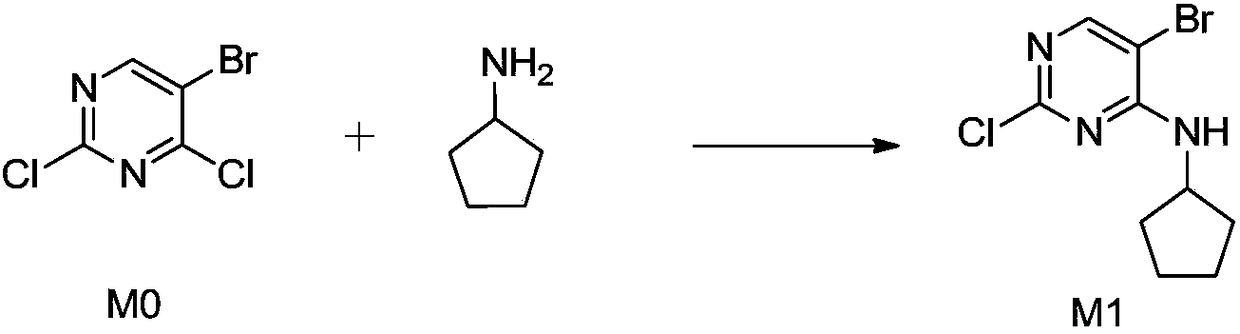

Embodiment 1

[0021] Add 2,4-dichloro-5-bromopyrimidine M0 (200g, 888mmol) and 1.4L dichloromethane into the reaction flask, add sodium bicarbonate (372g, 4440mmol), and slowly dropwise add 0.6L dichloromethane at room temperature Cyclopentylamine (90.7g, 1066mmol) diluted with methyl chloride, reacted at room temperature for 13h, filtered to remove sodium bicarbonate and the generated inorganic salts, rotary evaporated the mother liquor to remove dichloromethane, added 1.0L n-heptane for recrystallization, and obtained a white solid 236.7g, M1 yield 97.5%, purity >99.8%, impurity 5-bromo-4-chloro-2-cyclopentylaminopyrimidine <0.02%. Melting point: 94-96°C.

[0022] 1H NMR(DMSO-d6)δ(ppm):8.23(1H,s),7.35(1H,d),4.40–4.22(1H,m),1.98–1.84(2H,m),1.75–1.66(2H, m), 1.64–1.50 (4H, m).

Embodiment 2

[0024] 2,4-dichloro-5-bromopyrimidine M0 (100g, 444mmol) and 1.0L methyl tert-butyl ether were added to the reaction flask, potassium bicarbonate (444g, 4440mmol) was added, and slowly added dropwise at room temperature Cyclopentylamine (45.4g, 533mmol) diluted with 0.3L methyl tert-butyl ether, reacted at room temperature for 12h, removed potassium bicarbonate and the inorganic salts generated by suction filtration, rotary evaporation of the mother liquor removed methyl tert-butyl ether, added 0.5L Recrystallized from n-heptane to obtain 117.9 g of white solid, the yield of M1 was 97.1%, the purity was >99.8%, and the impurity 5-bromo-4-chloro-2-cyclopentylaminopyrimidine was <0.02%. Melting point: 94-96°C.

[0025] 1H NMR(DMSO)δ(ppm):8.23(1H,s),7.35(1H,d),4.40–4.22(1H,m),1.98–1.84(2H,m),1.75–1.66(2H,m) ,1.64–1.50(4H,m).

Embodiment 3

[0027] 2,4-dichloro-5-bromopyrimidine M0 (100g, 444mmol) and 1.0L dichloromethane were added to the reaction flask, potassium bicarbonate (444g, 4440mmol) was added, and slowly added dropwise with 0.3L dichloromethane at room temperature Cyclopentylamine (45.4g, 533mmol) diluted with methyl chloride, reacted at room temperature for 15h, removed potassium bicarbonate and generated inorganic salts by suction filtration, removed dichloromethane by rotary evaporation of the mother liquor, added 0.5L n-heptane for recrystallization, and obtained a white solid 117.5g, M1 yield 96.8%, purity >99.8%, impurity 5-bromo-4-chloro-2-cyclopentylaminopyrimidine <0.02%. Melting point: 94-96°C.

[0028] 1H NMR(DMSO)δ(ppm):8.23(1H,s),7.35(1H,d),4.40–4.22(1H,m),1.98–1.84(2H,m),1.75–1.66(2H,m) ,1.64–1.50(4H,m).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com