Crosslinkable polyethylene insulation material for high voltage direct current cable and preparation method thereof

A cross-linked polyethylene, high-voltage DC technology, applied in the field of cable materials, can solve the problems of short service life and poor oxidation resistance, and achieve the effects of increasing service life, delaying aging and degradation, and reducing the rate of auto-oxidative reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

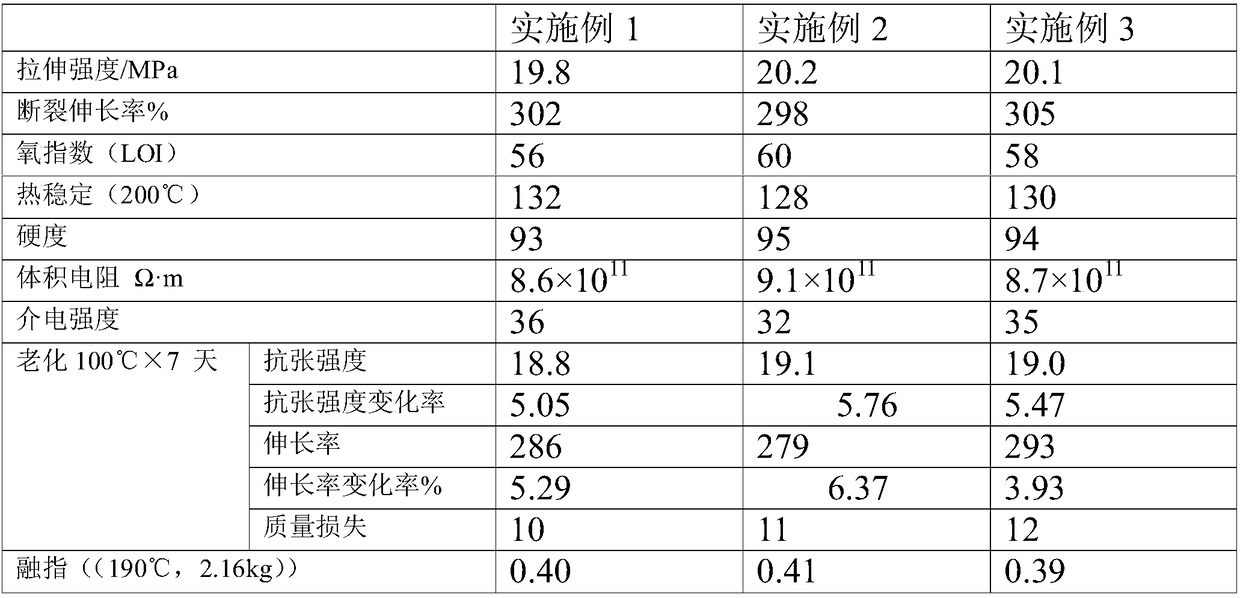

Examples

Embodiment 1

[0016] A cross-linkable polyethylene insulating material for high-voltage DC cables, comprising 80 parts of low-density polyethylene, 20 parts of polyphenylene ether resin, 3 parts of ethyl methacrylate, 3 parts of crosslinking agent, and composite anti- 1 part of oxygen agent, 1 part of nano-carbon material, the composite antioxidant includes 75 parts of antioxidant 300, 15 parts of antioxidant 1010, 3 parts of VE, 2 parts of guaiac resin, 10 parts of white carbon black .

[0017] Low-density polyethylene adopts NA207-66 of Taiwan Polymer Chemicals Co., Ltd.

[0018] The nano carbon material is carbon black.

[0019] The crosslinking agent is dicumyl peroxide.

[0020] Its preparation method comprises the following steps:

[0021] (1) Put low-density polyethylene, polyphenylene ether resin, ethyl methacrylate, cross-linking agent, composite antioxidant and nano-carbon material into the mixer in sequence and knead at a mixing temperature of 50°C and a rotation speed of 300r...

Embodiment 2

[0024] A cross-linkable polyethylene insulating material for high-voltage DC cables, comprising 90 parts of low-density polyethylene, 15 parts of polyphenylene ether resin, 4 parts of ethyl methacrylate, 3 parts of crosslinking agent, and composite anti- 2 parts of oxygen agent, 2 parts of nano-carbon material, the composite antioxidant includes 75 parts of antioxidant 300, 15 parts of antioxidant 1010, 3 parts of VE, 2 parts of guaiac resin, 10 parts of white carbon black .

[0025] Low-density polyethylene adopts NA207-66 of Taiwan Polymer Chemicals Co., Ltd.

[0026] Nano carbon material is graphene.

[0027] The crosslinking agent is dicumyl peroxide.

[0028] Its preparation method comprises the following steps:

[0029] (1) Put low-density polyethylene, polyphenylene ether resin, ethyl methacrylate, cross-linking agent, composite antioxidant and nano-carbon material into the mixer in sequence and knead at 40°C and at a speed of 400r / min, mixing time 18min;

[0030]...

Embodiment 3

[0032] A cross-linkable polyethylene insulating material for high-voltage DC cables, comprising 100 parts of low-density polyethylene, 10 parts of polyphenylene ether resin, 5 parts of ethyl methacrylate, 2 parts of crosslinking agent, and composite anti- 2 parts of oxygen agent, 3 parts of nano-carbon material, the composite antioxidant includes 75 parts of antioxidant 300, 15 parts of antioxidant 1010, 3 parts of VE, 2 parts of guaiac resin, 10 parts of white carbon black in parts by weight .

[0033] Low-density polyethylene adopts NA207-66 of Taiwan Polymer Chemicals Co., Ltd.

[0034] The nano carbon material is nano graphite.

[0035] The crosslinking agent is dicumyl peroxide.

[0036] Its preparation method comprises the following steps:

[0037] (1) Put low-density polyethylene, polyphenylene ether resin, ethyl methacrylate, cross-linking agent, composite antioxidant and nano-carbon material into the mixer in sequence and knead them. The mixing temperature is 30°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com