Polyester resin adhesive for ultrathin stretch-proof polyester belt

A polyester resin and stretch-resistant technology, which is applied in the field of polyester resin adhesives for ultra-thin stretch-resistant polyester tapes. To achieve the effect of facilitating use, improving antioxidant capacity, and reducing the speed of autoxidation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

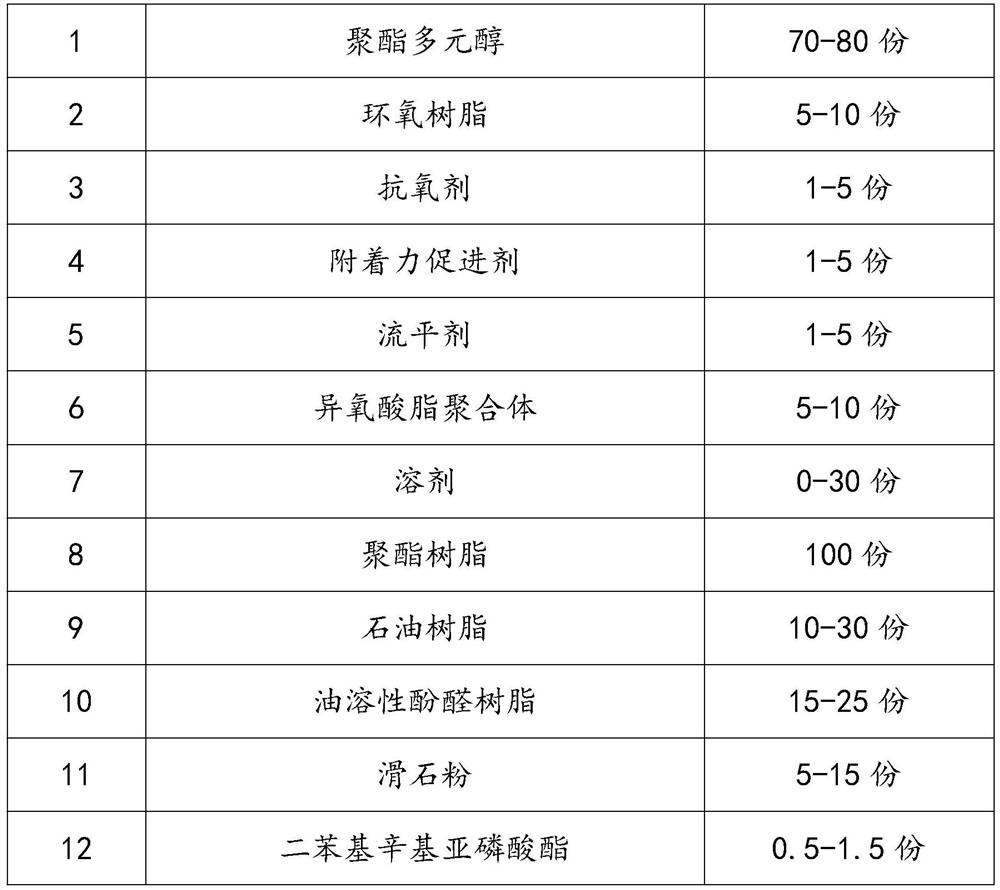

[0022] A polyester resin adhesive for ultra-thin stretch-resistant polyester tape, consisting of the following raw materials: 70-80 parts of polyester polyol, 5-10 parts of epoxy resin, 1-5 parts of antioxidant, adhesion promoter 1-5 parts, 1-5 parts of leveling agent, 5-10 parts of isooxyester polymer, 0-30 parts of solvent, 100 parts of polyester resin, 10-30 parts of petroleum resin, 15-25 parts of oil-soluble phenolic resin parts, 5-15 parts of talcum powder, and 0.5-1.5 parts of diphenyloctyl phosphite, and the parts are parts by mass.

[0023]

[0024]

[0025] According to the above examples, it can be seen that polyester polyol is the main resin, which is used to bond the ribbon substrate, epoxy resin can improve the heat resistance of the whole system, antioxidant can improve the oxidation resistance of the adhesive, adhesion promoter It can improve the bonding strength between the adhesive and the substrate, thus, the improved polyester resin adhesive greatly i...

Embodiment 2

[0027] Stir the polyester polyol and solvent at no higher than 80°C until the polyester polyol is completely dissolved, then cool down to below 40°C, add epoxy resin, antioxidant, adhesion promoter, leveling agent, Isooxyester polymer, polyester resin, petroleum resin, oil-soluble phenolic resin, talcum powder and diphenyloctyl phosphite, stir evenly, 77 parts of polyester polyol, 7 parts of epoxy resin, antioxidant 4 parts, 100 parts of polyester resin, 20 parts of petroleum resin, 20 parts of oil-soluble phenolic resin, 10 parts of talcum powder, 1 part of diphenyloctyl phosphite, and the parts are parts by mass.

[0028] serial number Element quantity 1 Polyester polyol 77 copies 2 epoxy resin 7 copies 3 antioxidant 4 parts 4 polyester resin 100 copies 5 petroleum resin 20 copies 6 Oil-soluble phenolic resin 20 copies 7 talcum powder 10 copies 8 diphenyloctyl phosphite 1 copy

[0029] According...

Embodiment 3

[0031] 3 parts of adhesion promoter, 2 parts of leveling agent, 8 parts of isooxyester polymer, 24 parts of solvent, 100 parts of polyester resin, 20 parts of petroleum resin, 15 parts of oil-soluble phenolic resin, 10 parts of talcum powder, two 1 part of phenyl octyl phosphite, the parts are parts by mass, the leveling agent can help the wettability of the adhesive on the substrate, and the isocyanate polymer is used to crosslink the polyester polyol resin to improve the viscosity of the adhesive Excellent heat resistance, the solvent is used to dissolve the resin and additives, reduce the viscosity, and facilitate the use.

[0032] serial number Element quantity 1 adhesion promoter 3 copies 2 leveling agent 2 copies 3 Isooxylate polymer 8 servings 4 solvent 24 copies 5 polyester resin 100 copies 6 petroleum resin 20 copies 7 Oil-soluble phenolic resin 15 copies 8 talcum powder 10 copies 9 diph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com