Thermoplastic elastomer used in automobile engine, having temperature resistance grade of 150 DEG C and having oxygen resistance and oil resistance and preparation method thereof

A thermoplastic elastomer, automotive engine technology, applied in the field of thermoplastic elastomer and its preparation, can solve the problems of intolerance to 150 ° C, poor ACM processing performance, poor storage stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

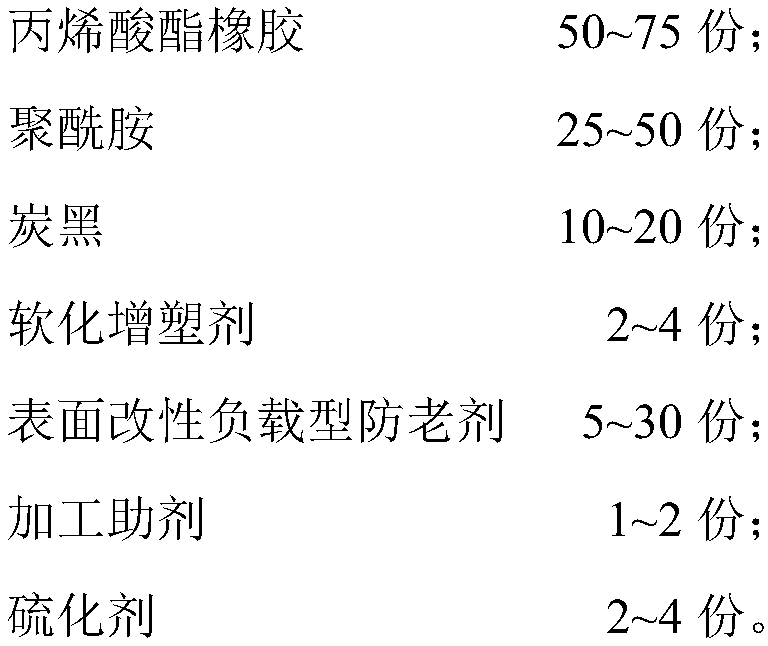

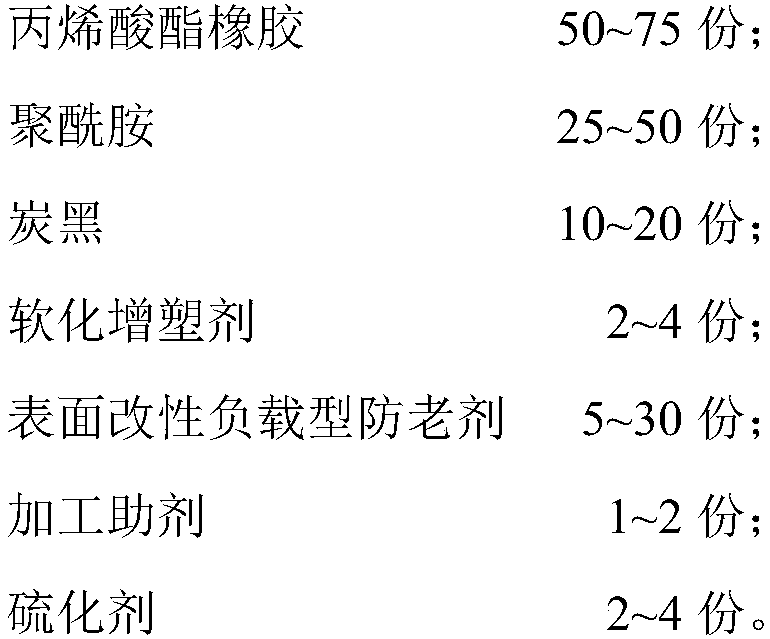

[0034] The preparation method of the temperature-resistant 150°C grade oxygen-resistant and oil-resistant thermoplastic elastomer used in automobile engines is characterized in that it includes the following steps:

[0035] 1) Preparation of surface-modified loaded anti-aging agent: first dissolve the anti-aging agent in an organic solvent to obtain an anti-aging agent solution, then add halloysite nanotubes into the anti-aging agent solution, stir evenly, then vacuumize and vent into the atmosphere Circulating treatment, washing, and then dispersing the halloysite nanotubes loaded with anti-aging agent into water, adding a silane coupling agent and stirring evenly, separating the solid product, and drying to obtain a surface-modified loaded anti-aging agent;

[0036] 2) Mixing: Weigh the raw materials according to the above composition, first put the acrylate rubber, surface-modified loaded anti-aging agent, and processing aid into the internal mixer for mixing, then add carbo...

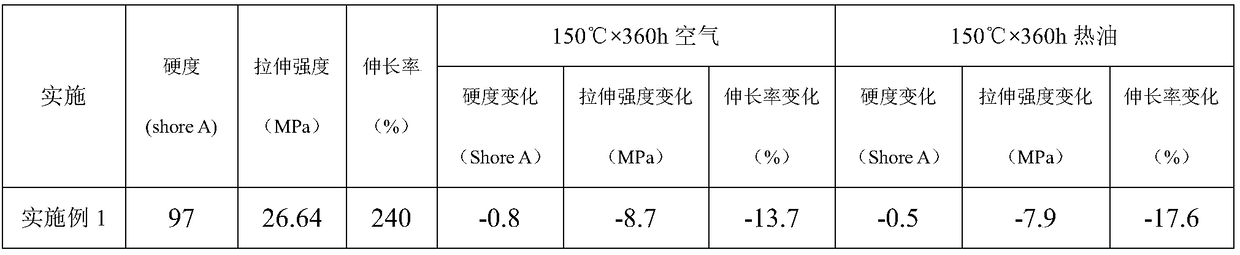

Embodiment 1

[0052] Example 1 A method for preparing a thermoplastic elastomer for internal use in an automobile engine with a temperature resistance of 150°C, oxygen resistance, and oil resistance, including:

[0053] 1) Preparation of silane-modified loaded anti-aging agent: 30.08 g of anti-aging agent MC445 was dissolved in 1 L of acetone to prepare an anti-aging agent solution with a concentration of 30 g / L. Add 60.12g HNT to the anti-aging agent solution, stir and disperse evenly, ventilate to the atmosphere after negative pressure for half an hour, repeat 3 times; filter with suction, and rinse 3 times with 75% ethanol solution to remove the anti-aging agent MC445 attached to the surface. Disperse the obtained solid in 100mL distilled water again, add 3.05g KH570, react at 60°C for 30min, centrifuge, dry and grind for later use.

[0054] 2) Mixing: Weigh 52.04g of acrylate rubber AR840, 5.87g of load-type anti-aging agent, 0.52g of stearic acid, 0.38g of VANFRE VAM and 0.43g of 935P ...

Embodiment 2

[0057] Example 2 A method for preparing a thermoplastic elastomer used in an automobile engine with a temperature resistance of 150°C, oxygen resistance, and oil resistance, including:

[0058] 1) Preparation of silane-modified loaded anti-aging agent: 30.08 g of anti-aging agent MC445 was dissolved in 1 L of acetone to prepare an anti-aging agent solution with a concentration of 30 g / L. Add 60.12g HNT to the anti-aging agent solution, stir and disperse evenly, ventilate to the atmosphere after negative pressure for half an hour, repeat 3 times; filter with suction, and rinse 3 times with 75% ethanol solution to remove the anti-aging agent MC445 attached to the surface. Disperse the obtained solid in 100mL distilled water again, add 3.05g KH570, react at 60°C for 30min, centrifuge, dry and grind for later use.

[0059] 2) Mixing: Weigh 60.24g of acrylate rubber AR51, 17.35g of load-type anti-aging agent, 0.60g of stearic acid, 0.46g of VANFRE VAM and 0.52g of 935P respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com