Environment-friendly solvent-free polyurethane synthetic leather and manufacturing method thereof

A solvent-free polyurethane and synthetic leather technology, applied in textiles and papermaking, can solve problems such as low peel strength, poor adhesion, and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

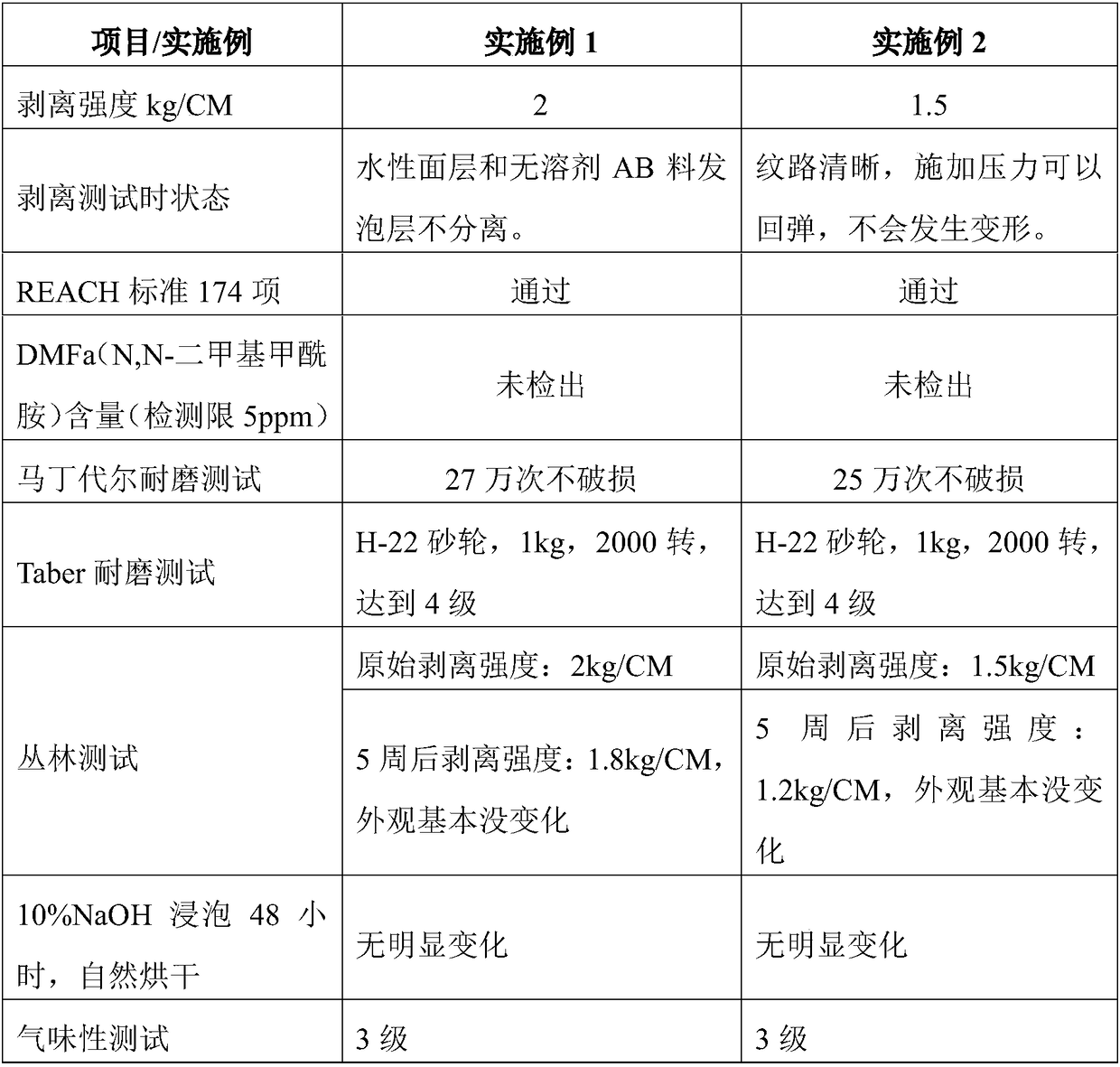

Embodiment 1

[0026] Embodiment 1 environment-friendly solvent-free polyurethane synthetic leather and preparation method thereof

[0027] Environmentally friendly solvent-free polyurethane synthetic leather, including base fabric, water-based surface layer, water-based adhesive layer and solvent-free AB material foaming layer: The water-based adhesive layer is mainly composed of the following components by weight. Water-based polyurethane adhesive layer slurry mixing Prepared: 1000 parts of water-based polyurethane emulsion, 100 parts of water-based polyurethane crosslinking agent and 60 parts of water-based color paste; the solvent-free AB material foaming layer is mainly composed of the following parts by weight AB material foaming layer slurry is prepared by mixing Preparation: 800 parts of mixed polyol, 30 parts of organic metal catalyst, 90 parts of organic amine catalyst, 2000 parts of filler and 1500 parts of isocyanate.

[0028] When preparing the water-based surface layer, it is p...

Embodiment 2

[0036] Embodiment 2 environment-friendly solvent-free polyurethane synthetic leather and preparation method thereof

[0037]Environmentally friendly solvent-free polyurethane synthetic leather, including base fabric, water-based surface layer, water-based adhesive layer and solvent-free AB material foaming layer: The water-based adhesive layer is mainly composed of the following components by weight. Water-based polyurethane adhesive layer slurry mixing Prepared: 800 parts of water-based polyurethane emulsion, 80 parts of water-based polyurethane crosslinking agent and 50 parts of water-based color paste; the solvent-free AB material foam layer is mainly prepared by mixing the AB material foam layer slurry composed of the following parts by weight Preparation: 800 parts of mixed polyol, 30 parts of organic metal catalyst, 90 parts of organic amine catalyst, 2000 parts of filler and 1500 parts of isocyanate.

[0038] When preparing the water-based surface layer, it is preferred...

Embodiment 3

[0046] Embodiment 3 environment-friendly solvent-free polyurethane synthetic leather and preparation method thereof

[0047] Environmentally friendly solvent-free polyurethane synthetic leather, including base fabric, water-based surface layer, water-based adhesive layer and solvent-free AB material foaming layer: The water-based adhesive layer is mainly composed of the following components by weight. Water-based polyurethane adhesive layer slurry mixing Prepared: 800 parts of water-based polyurethane emulsion, 80 parts of water-based polyurethane crosslinking agent and 50 parts of water-based color paste; the solvent-free AB material foam layer is mainly prepared by mixing the AB material foam layer slurry composed of the following parts by weight Preparation: 800 parts of mixed polyol, 30 parts of organic metal catalyst, 90 parts of organic amine catalyst, 2000 parts of filler and 1500 parts of isocyanate.

[0048] When preparing the water-based surface layer, it is preferre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com