Anti-magnetic levitation wind power energy collector

An energy harvester and magnetic levitation technology, which is used in wind energy generation, wind turbines, wind turbine combinations, etc., can solve the problems of inability to generate electricity, wind direction requirements, and large friction of components, so as to improve the utilization rate of wind energy, increase the wind area, The effect of omitting the bearing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

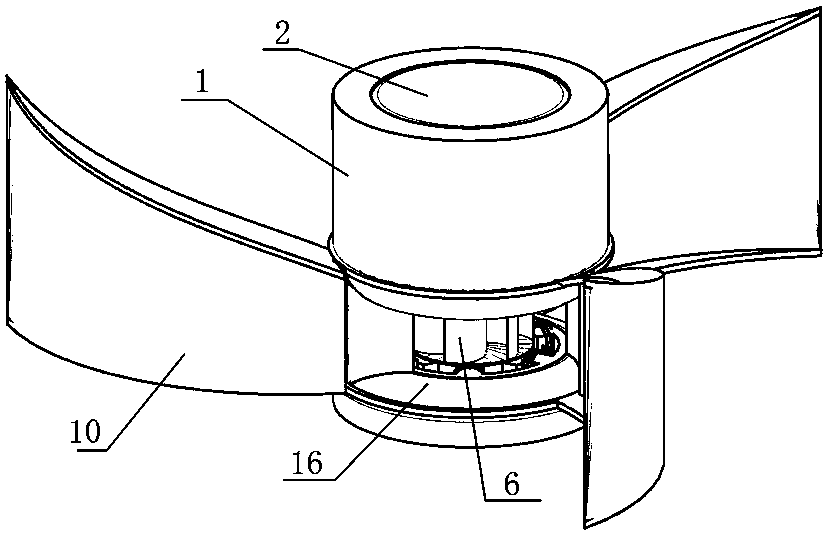

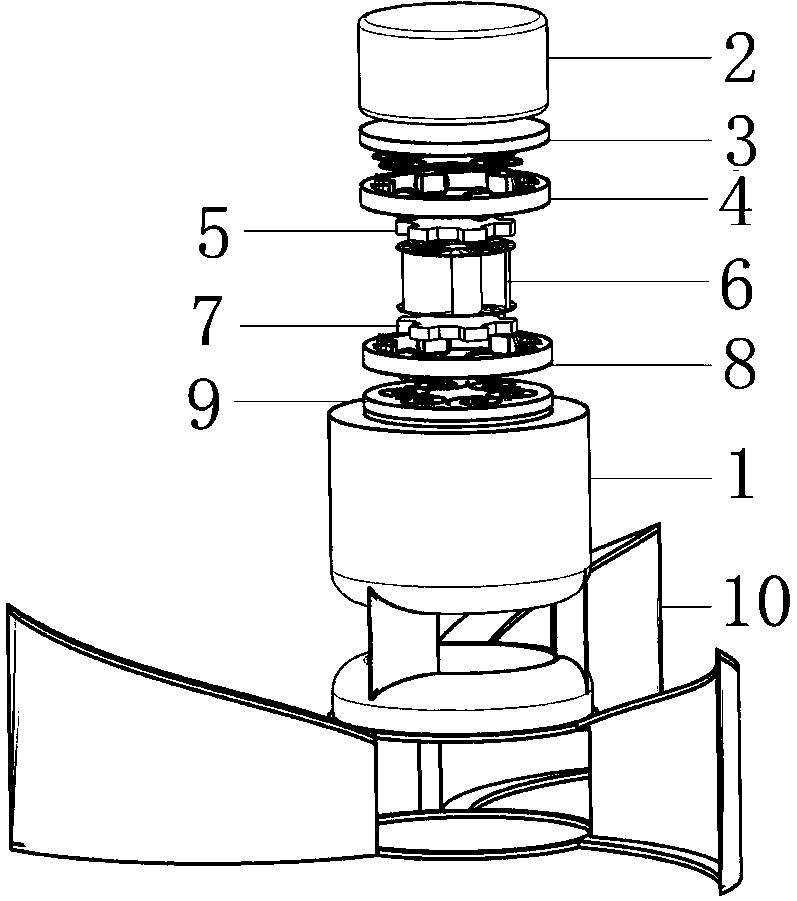

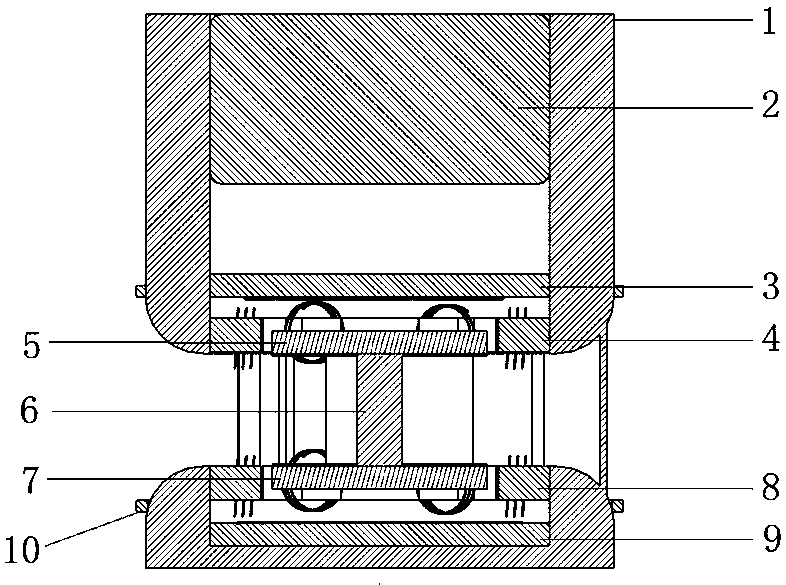

[0024] Such as Figure 1-Figure 5 As shown, an anti-magnetic levitation wind energy harvester includes a housing 1, a permanent magnet 2 installed in the housing, an upper pyrolytic graphite plate 3, an upper stator 4, an upper permanent magnet rotor 5, fan blades 6, and a lower permanent magnet rotor 7. The magnetization directions of the lower stator 8 and the lower pyrolytic graphite plate 9, the permanent magnet 2, the upper permanent magnet rotor 5 and the lower permanent magnet rotor 7 are the same, and the materials of the permanent magnet, the upper permanent magnet rotor and the lower permanent magnet rotor can be magnetic The strongest NdFeB. In order to facilitate assembly, a port can be provided on the top of the shell 1, so that the shell 1 is similar to a barrel-shaped structure. Of course, the shell 1 can also be designed as a structure formed by butting two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com