PCB board and IGBT module crimping structure and crimping method

A PCB board and connection structure technology, which is applied in the field of microelectronics, can solve problems such as poor error-proofing ability and increased contact point impedance, and achieve the effects of convenient maintenance, avoiding heat concentration, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

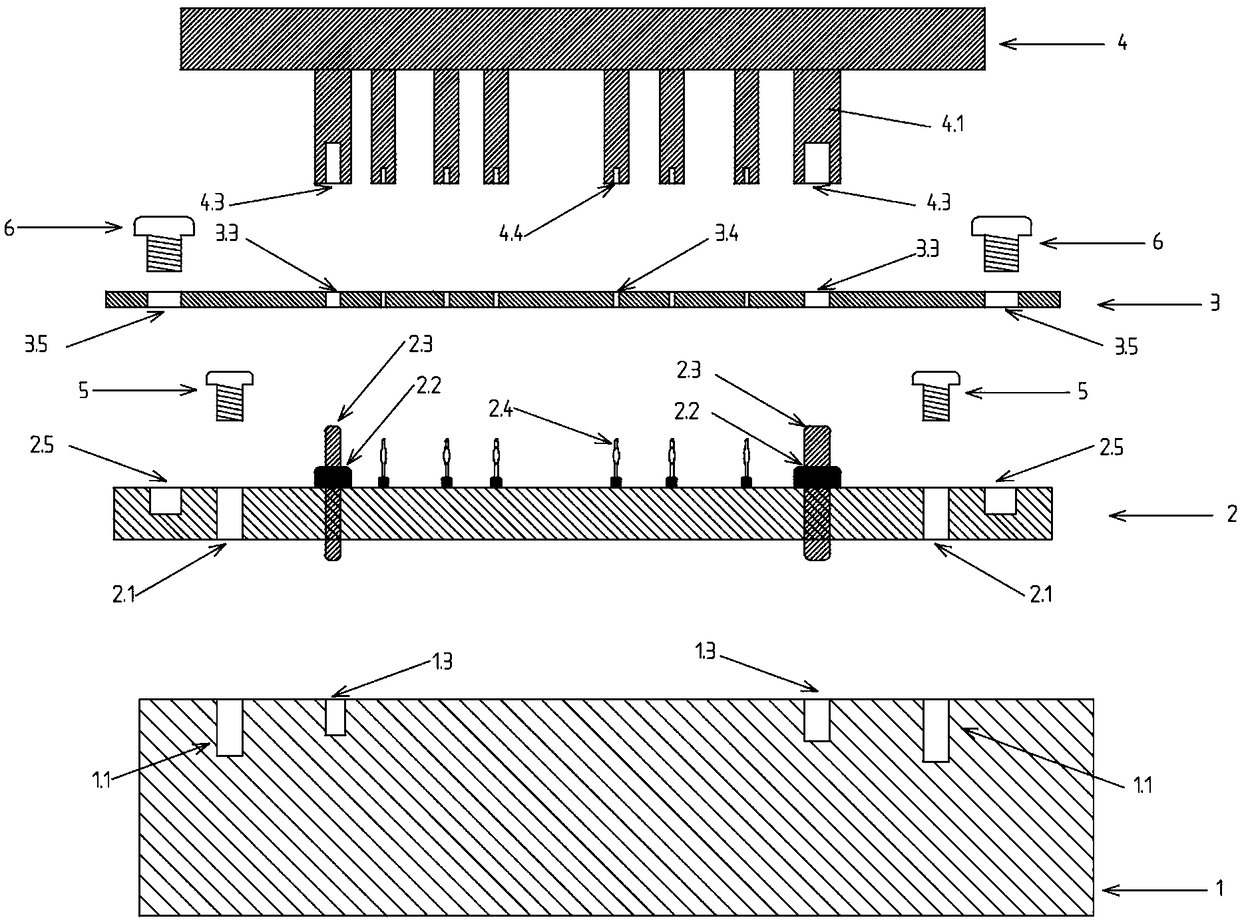

[0047] Such as figure 1An exploded view of the crimping structure between the PCB board and the IGBT module is shown, including the sequential settings from bottom to top:

[0048] A water cooling plate 1, the water cooling plate is provided with positioning pin holes 1.3 of the water cooling plate and threaded holes 1.1 of the water cooling plate;

[0049] The IGBT module 2 is fixedly provided with through positioning pins 2.3 and crimping pins 2.4, preferably two positioning pins. Further preferably, the two positioning pins have different diameters, one is large and the other is small. Can play a foolproof role. The number of crimping pins is selected according to the size of the structure. The lower end of the positioning pin 2.3 cooperates with the positioning pin hole 1.3 of the water-cooled plate, so that the IGBT module 2 is relatively positioned with the water-cooled plate 1. The IGBT module 2 is connected by the IGBT module screw 5 Through the through hole 2.1 of ...

Embodiment 2

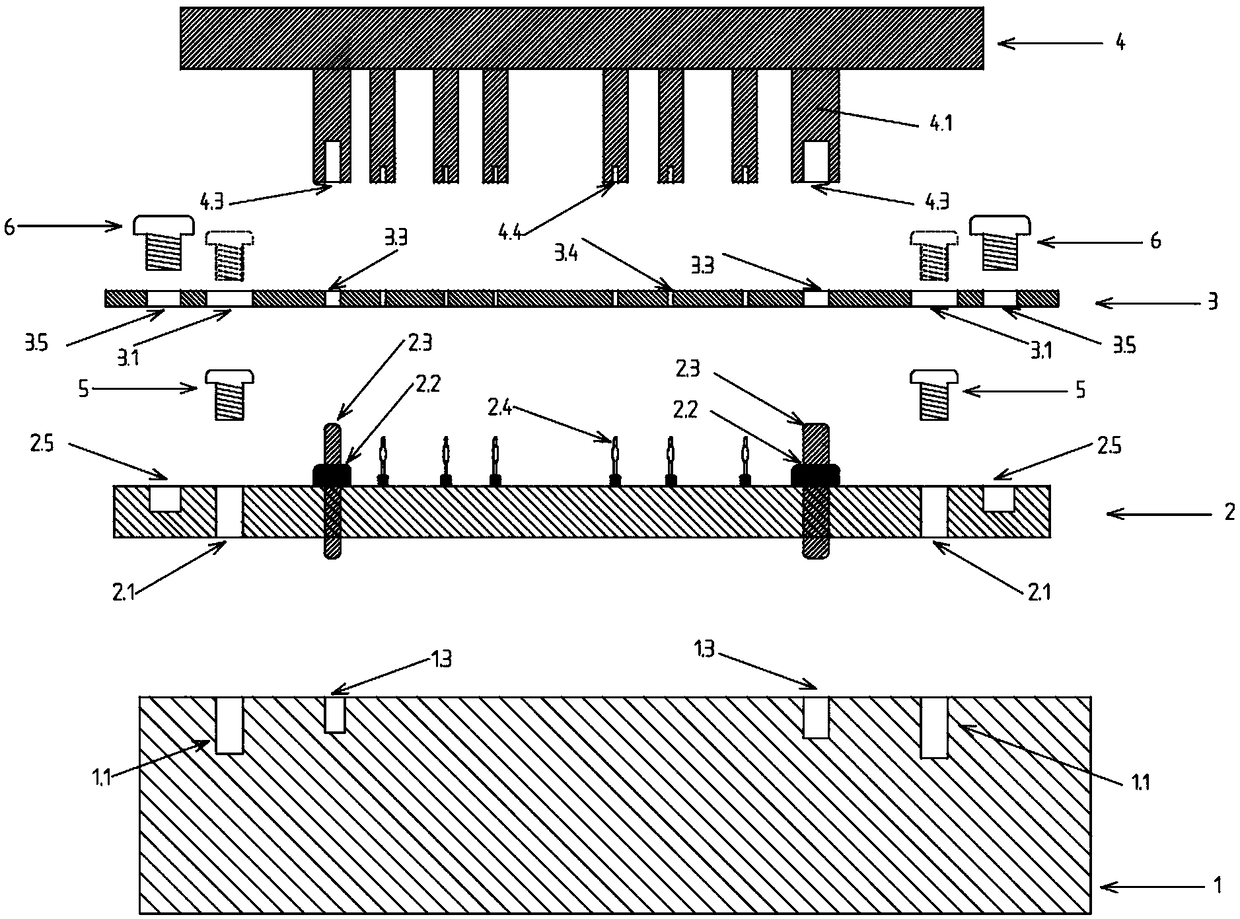

[0053] Such as figure 2 The explosion diagram of the crimping structure between the PCB board 3 and the IGBT module 2 is shown. On the basis of the embodiment 1, the position corresponding to the IGBT module screw 5 on the PCB board 3 is provided with a PCB board through hole 3.1, and The diameter of the PCB through hole 3.1 is larger than the nut diameter of the IGBT module screw 5 .

Embodiment 3

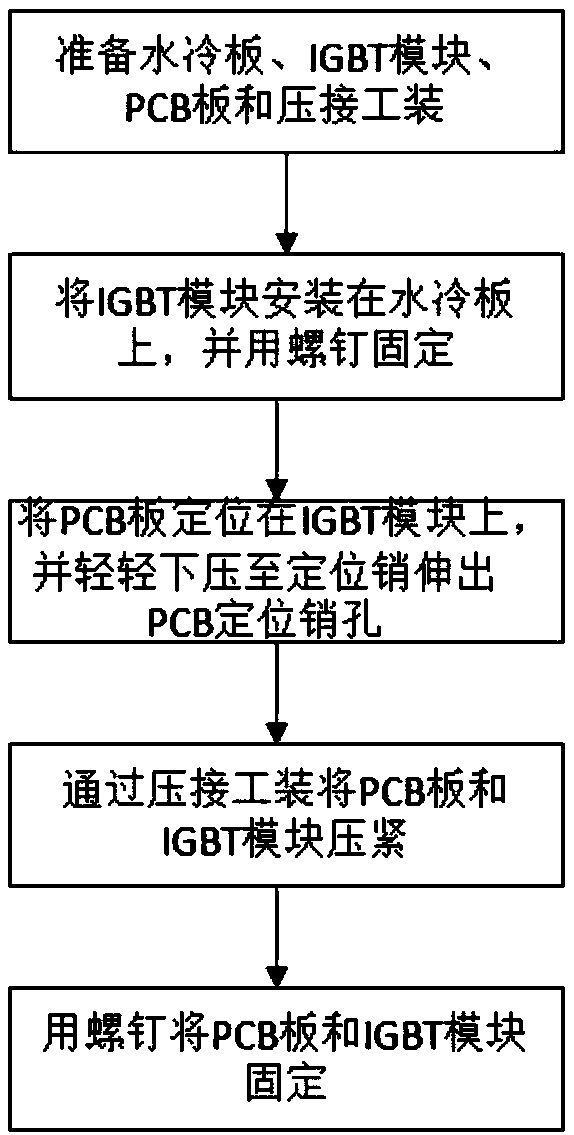

[0055] Such as figure 1 and 3 As shown, the embodiment of the present invention also provides a method for crimping a PCB board and an IGBT module, including the following steps:

[0056] Prepare the water-cooled plate 1, and drill out the water-cooled plate positioning pin hole 1.3 and the water-cooled plate threaded hole 1.1 on the water-cooled plate 1 in advance;

[0057] Prepare the IGBT module 2, pre-set the positioning pin 2.3 fixed on the IGBT module 2 and through the IGBT module 2 on the IGBT module 2, and fix a plurality of crimping pins 2.4 on the upper side of the IGBT module 2, so The IGBT module 2 is reserved with the IGBT module through hole 2.1 and the PCB board screw fixing hole 2.5 through the IGBT module screw, and the height-limiting boss 2.2 is set at the position of the IGBT module positioning pin 2.3, and the height-limiting boss 2.2 is close to the above the IGBT module 2;

[0058] Prepare the PCB board 3, reserve the PCB board crimping hole 3.4, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com