Adaptive Drilling Method Based on Simple Harmonic Vibration Chip Breaking

A simple harmonic vibration and drilling technology, used in metal processing, metal processing equipment, metal processing machinery parts, etc., to achieve the effect of improving processing quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] This embodiment relates to an experimental platform for composite material / alloy laminated automatic drilling equipment, including: a monitoring feedback system, a simple harmonic vibration drilling system and a parameter database system.

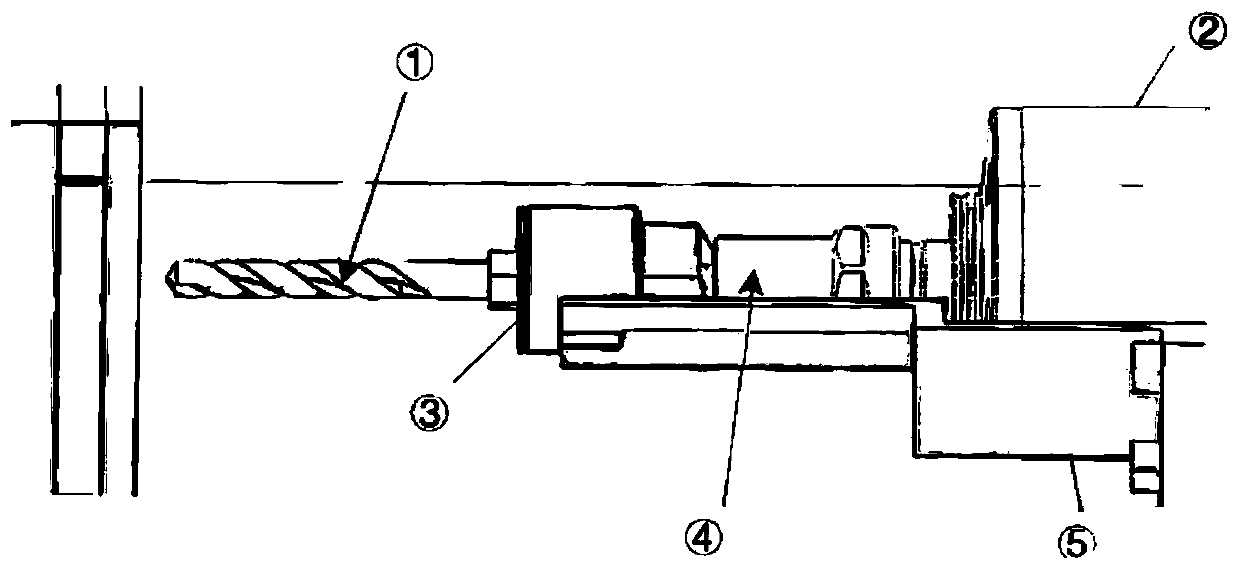

[0019] Such as figure 1 As shown, the simple harmonic vibration drilling system includes: a thread cutter 1, a low-frequency vibration drilling device 3, an adapter 4 and an electric spindle 2 connected in sequence, and the outer side of the electric spindle 2 is further provided with a low-frequency vibration drilling device 3 limit brackets 5 in contact with each other.

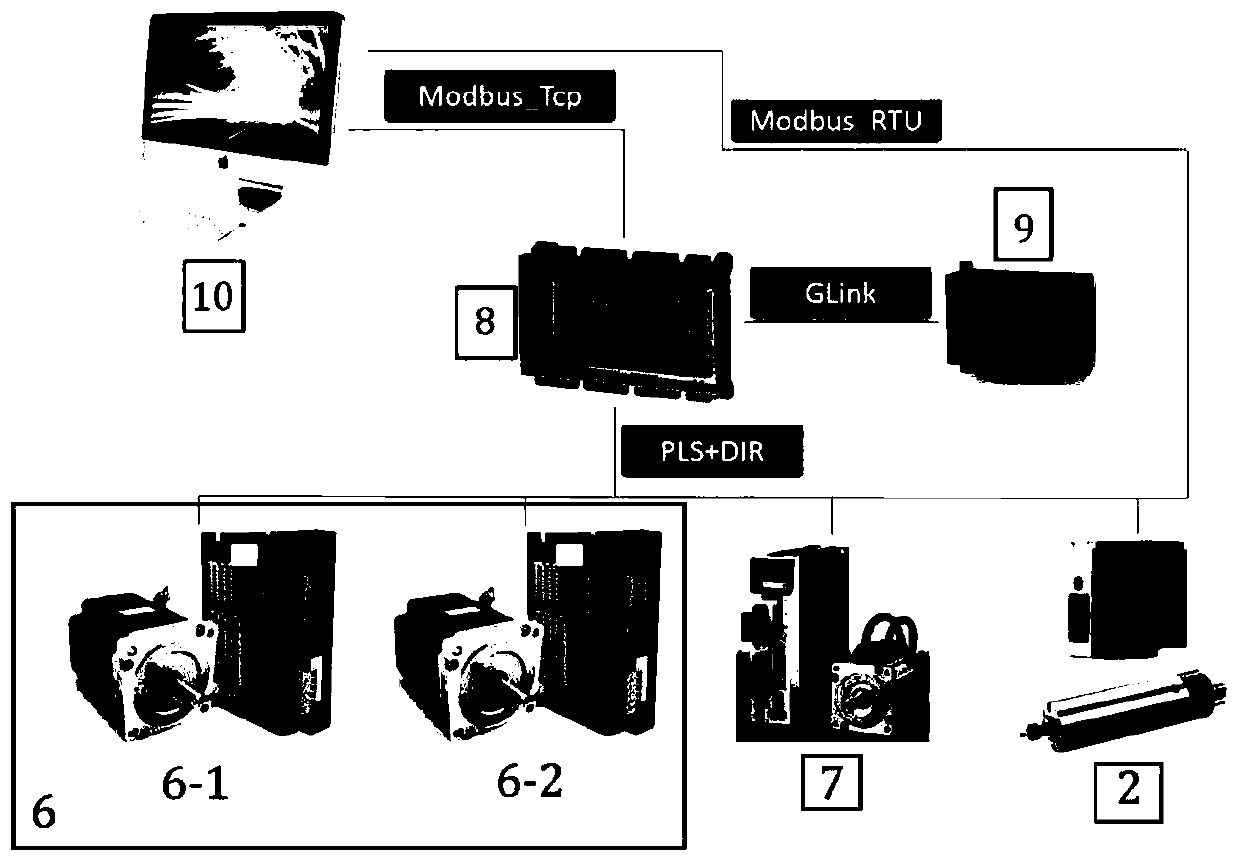

[0020] Such as figure 2 As shown, the monitoring feedback system includes: a motor driver 6 composed of a left and right driver 6-1, an up and down driver 6-2, a feed driver 7, a multi-axis motion control unit 8, a data acquisition unit 9 and an industrial control unit 10, Among them: the industrial control unit 10 is connected with the multi-axis motion contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com