18CrNiMo7-6 steel carburization element shot blasting process

A technology of shot peening and carburizing, applied to spray guns, manufacturing tools, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

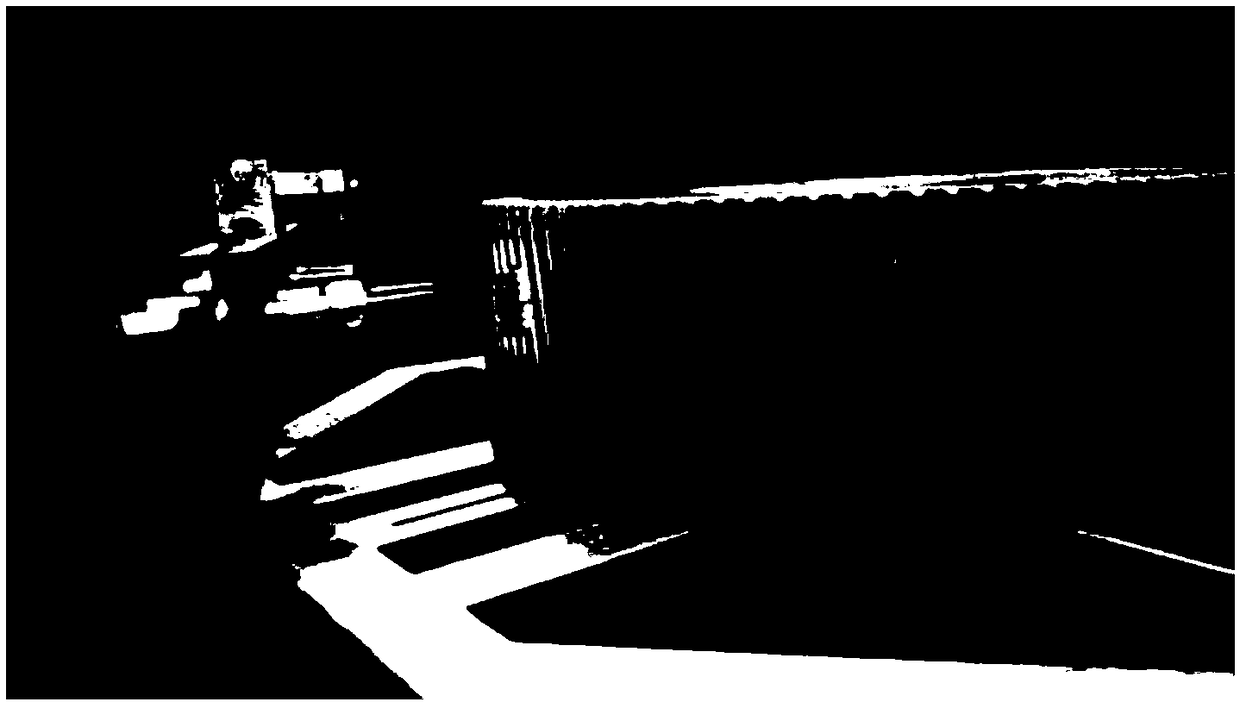

[0048] The shot peening process parameters are shown in Table 2.

[0049] Table 2 Process parameters (gear diameter 1000mm)

[0050]

[0051] Perform performance testing on the products after shot peening.

[0052] Detection conditions: Proto-LXRD X-ray stress analyzer, tube voltage 30kV, tube current 25mA, Cr target K. Radiation, V filter, collimator diameter 1mm, Fe(211) diffraction crystal plane, X-ray elastic constant S 2 / 2=5.75×10-6 MPa -1 and S l =-1.28×10 -6 MPa -1 , left and right dual 512-channel position-sensitive detectors, corresponding to a 2θ range of 19°, 17 stations are optimally set within ±45°, co-inclined diffraction geometry, and ASTM-E915-2010, EN15305-2008 and GB7704-2008 standards are implemented for testing. With the help of Proto-8818 electrolytic polishing machine electrochemical corrosion, parameters 15V and 2A, saturated NaCl water electrolyte, digital display micrometer to measure the corrosion depth.

[0053] The test results of the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com