System for realizing zero emission of wastewater and waste residues of pre-mixed concrete industry

A technology for ready-mixed concrete and industrial wastewater, applied in mixing plants, clay preparation devices, mixing operation control, etc., can solve problems such as secondary pollution, and achieve the effects of good performance, saving time and energy consumption, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

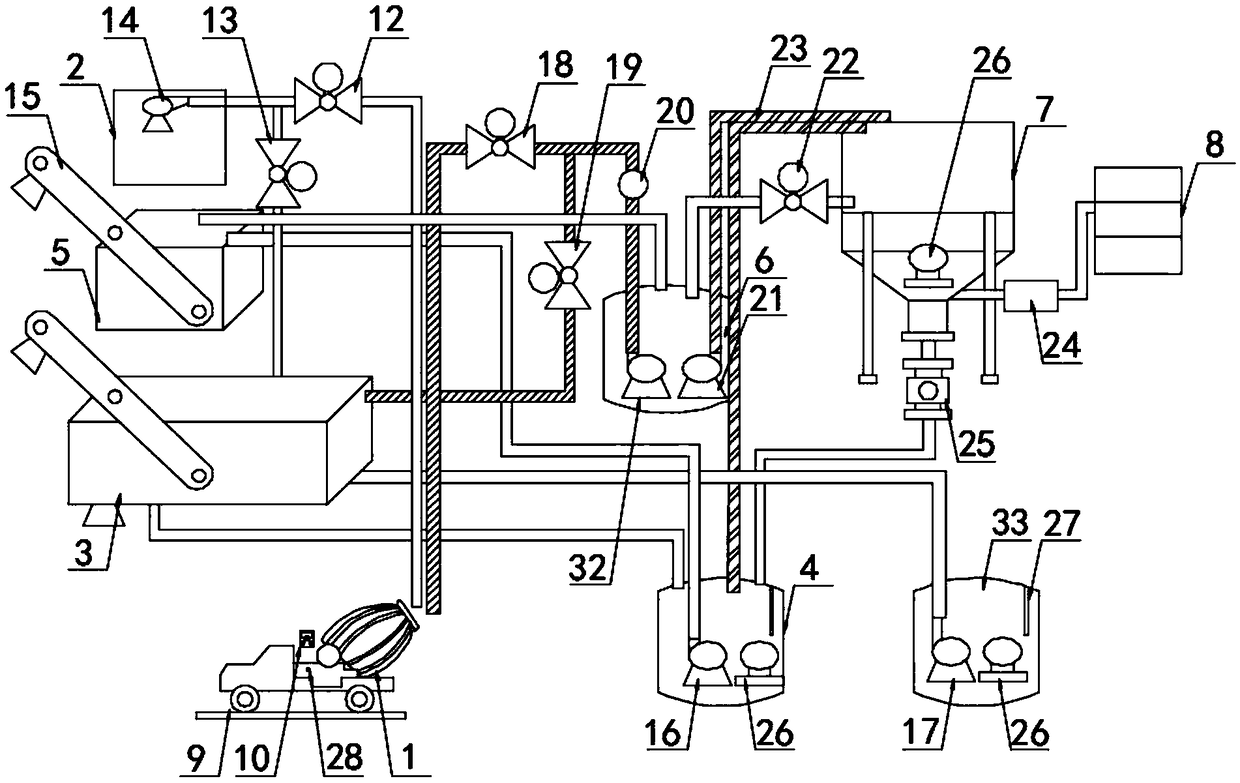

[0032] according to Figure 1-2 The shown system for realizing zero discharge of waste water and slag in the ready-mixed concrete industry includes a scrubbing mixer truck 1, the input end of the scrubbing mixer truck 1 is provided with a clear water pool 2 and the output end is provided with a sand and stone separator 3, and the sand and gravel The output end of the separator 3 is provided with No. 1 first-level slurry tank 4 and No. 2 first-level slurry tank 33, and the output end of the No. 1 first-level slurry tank 4 is provided with a fine sand separator 5 and a second-level slurry tank connected successively by pipelines. Tank 6, slurry storage tank 7 and mixing building 8, the input end of the fine sand separator 5 is connected to the clear water tank 2, and the input end of the secondary slurry tank 6 is connected to the scrubbing mixer truck 1 and the fine sand separator through a three-way pipeline 5 connection, the bottom of the slurry storage tank 7 is connected to...

Embodiment 2

[0043] The present invention also provides a system for realizing zero discharge of waste water and residue in the ready-mixed concrete industry. The specific operation steps are as follows:

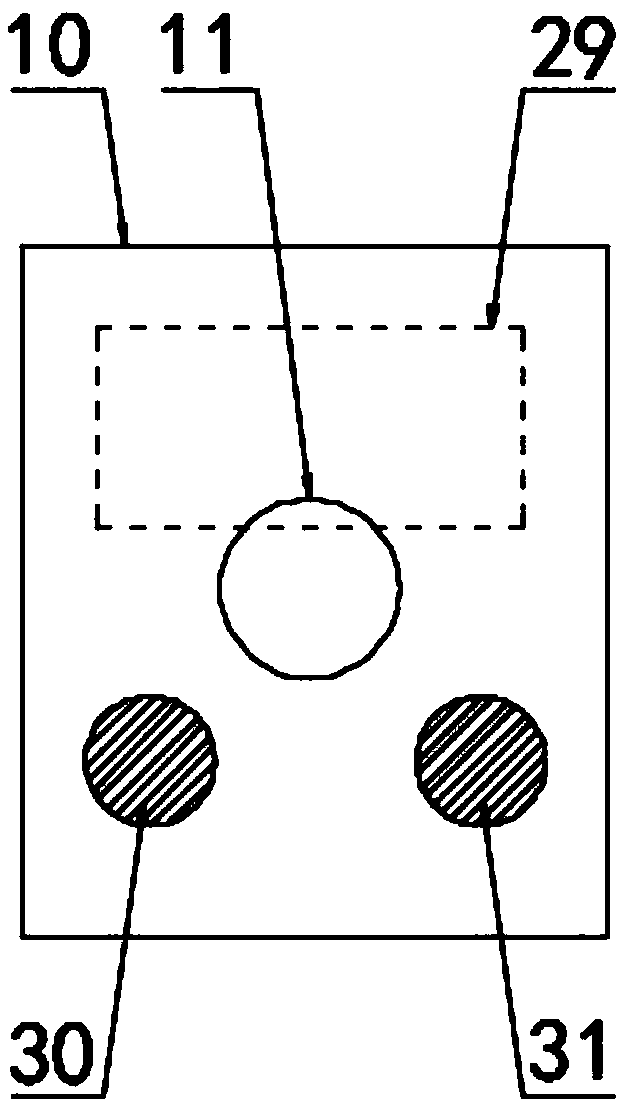

[0044] Step 1: When the scrubbing mixer truck 1 enters the parking space 9, the infrared receiver 11 on the control box 10 can receive the infrared signal emitted by the infrared transmitter 28 on the scrubbing mixer truck 1, and then send the control signal to the PLC controller 29 , the PLC controller 29 controls the operation of the entire system;

[0045] Step 2: When cleaning, the No. 1 water pump 14, No. 1 valve 12, and No. 2 valve 13 are turned on, and clean water enters the scrubbing mixer 1 to clean the concrete attached to the inner wall. The cleaning time is 90 seconds, and the cleaned mixed liquid flows into the sand The stone separator 3 and the sand separator 3 work for 120 seconds, and compared with the scrubbing mixer 1, the sand separator 3 is delayed for 30 seconds to s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com