Ternary rare-earth doped polyacid derivative as well as preparation method and application of ternary rare-earth doped polyacid derivative serving as fluorescent luminescent material

An acid derivative, rare earth doping technology, applied in luminescent materials, organic chemistry methods, chemical instruments and methods, etc., can solve the problems of staying, less research on polyacid derivatives, etc., and achieve low cost, high energy transfer efficiency, The effect of less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

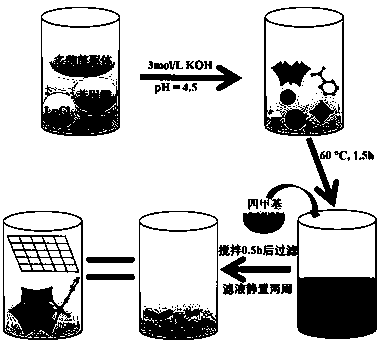

[0032] A kind of preparation method of polyacid derivative containing Eu rare earth, it specifically comprises the following steps:

[0033] EuCl 3 ∙6H 2 O (0.228 g, 0.600 mmol), benzoic acid (0.244 g, 0.200 mmol) and polyacid precursor K 14 [P 2 W 19 o 69 (H 2 O)]∙24H 2 O (2.120 g, 0.465 mmol) was added into 30 mL of distilled water and stirred until completely dissolved. Adjust the pH value to 4.5 with 3 mol / L KOH aqueous solution, and stir at room temperature for 20-30 min. Put the solution into a water bath at 60°C and stir and heat for 1.5 h, then add tetramethylammonium chloride (0.110 g, 1.000 mmol) while it is hot and stir for 20-30 min. After the reaction, the solution is cooled and filtered. After standing for two weeks, colorless blocky crystals were precipitated, and the target product 1 was obtained.

Embodiment 2

[0035] A kind of preparation method of polyacid derivative containing Tb rare earth, it specifically comprises the following steps:

[0036] TbCl 3 ∙6H 2 O (0.228 g, 0.600 mmol), benzoic acid (0.244 g, 0.200 mmol) and polyacid precursor K 14 [P 2 W 19 o 69 (H 2 O)]∙24H 2 O (2.120 g, 0.465 mmol) was added to 30 mL of distilled water and stirred until completely dissolved. Adjust the pH value to 4.5 with 3 mol / L KOH solution, and stir at room temperature for 20-30 min. Put the solution into a water bath at 60°C, stir and heat for 1.5 h, then add tetramethylammonium chloride (0.110 g, 1.000 mmol) while hot, and stir for 20-30 min. After the reaction, the solution is cooled and filtered, and the filtrate is static After standing for two weeks, colorless blocky crystals were precipitated, and the target product 2 was obtained.

Embodiment 3

[0038] A kind of preparation method of polyacid derivative containing Tm rare earth, it specifically comprises the following steps:

[0039] TmCl 3 ∙6H 2 O (0.228 g, 0.600 mmol), benzoic acid (0.244 g, 0.200 mmol) and polyacid precursor K 14 [P 2 W 19 o 69 (H 2 O)]∙24H 2 O (2.120g, 0.465mmol) was added to 30 mL of distilled water and stirred until completely dissolved. Adjust the pH value to 4.5 with 3mol / L KOH solution, and stir at room temperature for 20-30 min. Put the solution into a water bath at 60°C and stir for 1.5 h, then add tetramethylammonium chloride (0.110 g, 1.000 mmol) while it is still hot, and stir for 20-30 min. After the reaction, the solution is cooled and filtered, and the filtrate After standing for two weeks, colorless blocky crystals were precipitated, and the target product 3 was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com