A kind of method utilizing simulated moving bed to separate d-fructose and d-psicose

A technology for simulating moving bed and allulose, applied in chemical instruments and methods, monosaccharides, sugar derivatives, etc., can solve the problem of low purity of allulose and fructose, limited market scale and application, high price, etc. problems, achieve high purity and recovery, reduce production costs, and reduce the number of uses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for separating D-fructose and D-psicose using a simulated moving bed, comprising the following steps:

[0037] (1) Conversion of D-psicose: D-fructose is converted into D-psicose by immobilized D-psicose epimerase nanospheres to obtain D-fructose and D-alpha Mixed sugar solution of ketose;

[0038] (2) Pretreatment of the mixed sugar solution: dilute the mixed solution of D-fructose and D-psicose with water to a sugar content of 5%, vacuum filter with a 0.45 μm filter membrane to remove impurities, and then pass through a granular carbon chromatographic column. Decolorization pretreatment to obtain mixed sugar liquid raw materials;

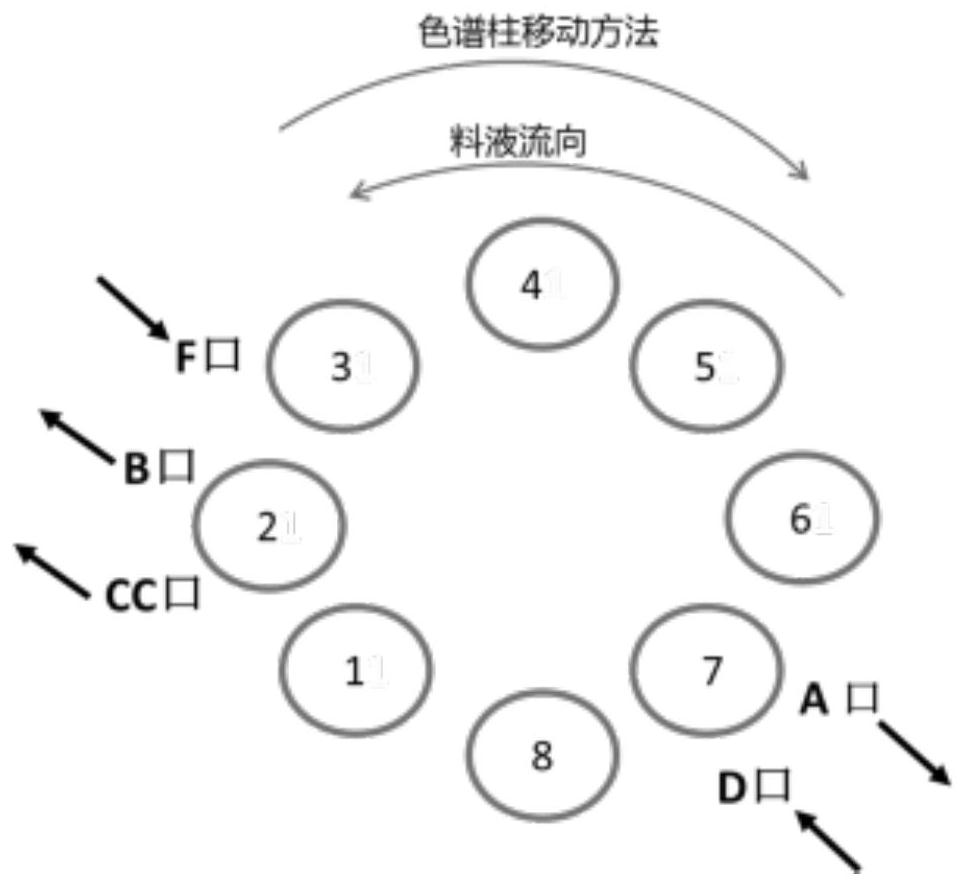

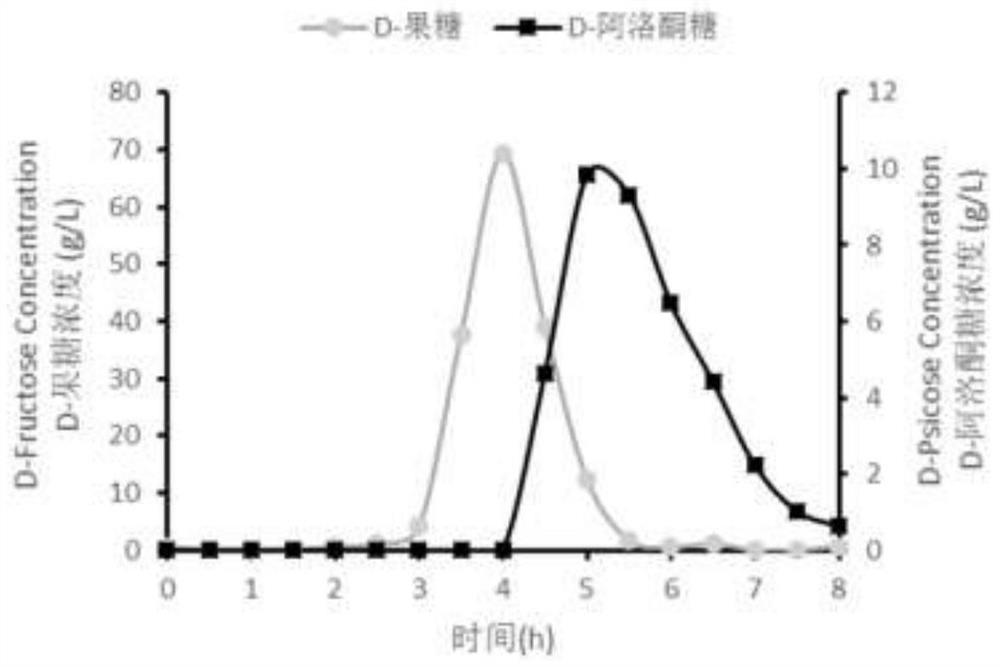

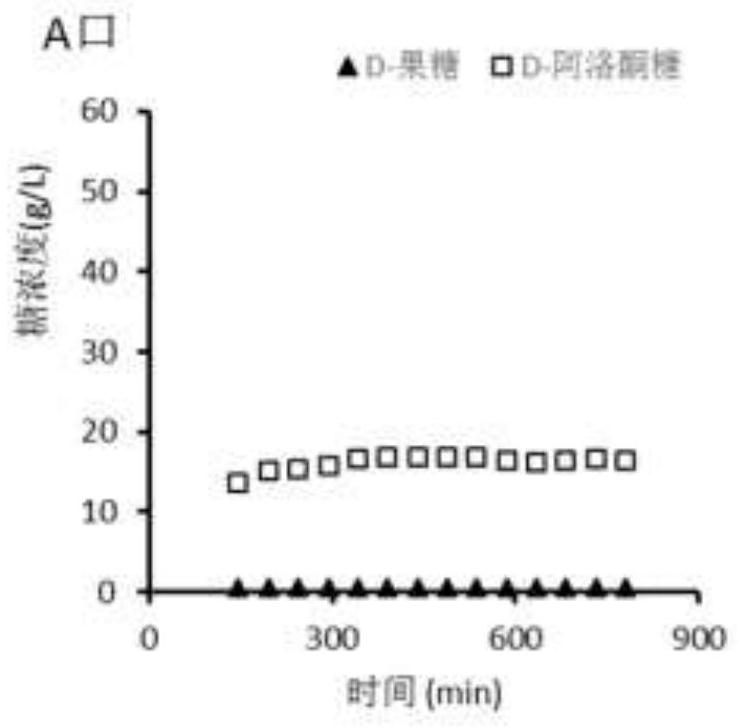

[0039] (3) Sequential simulated moving bed separation: such asfigure 1 As shown, the pretreated mixed sugar solution is separated by sequential simulated moving bed chromatography equipment, and the equipment is distributed by a rotary valve with 12 inlets and 13 outlets, and 8 ring-connected adsorption separation Column and 4 co...

Embodiment 2

[0049] A method for separating D-fructose and D-psicose using a simulated moving bed, comprising the following steps:

[0050] (1) Conversion of D-psicose: D-fructose is converted into D-psicose by immobilized D-psicose epimerase nanospheres to obtain D-fructose and D-alpha Mixed sugar solution of ketose;

[0051] (2) Pretreatment of the mixed sugar solution: dilute the mixed solution of D-fructose and D-psicose with water to a sugar content of 8%, vacuum filter with a 0.45 μm filter membrane to remove impurities, and then pass through a granular carbon chromatographic column. Decolorization pretreatment to obtain mixed sugar liquid raw materials;

[0052] (3) Sequential simulated moving bed separation: such as figure 1 As shown, the pretreated mixed sugar solution is separated by sequential simulated moving bed chromatography equipment, and the equipment is distributed by a rotary valve with 12 inlets and 13 outlets, and 8 ring-connected adsorption separation Column and 4 ...

Embodiment 3

[0062] A method for separating D-fructose and D-psicose using a simulated moving bed, comprising the following steps:

[0063] (1) Conversion of D-psicose: D-fructose is converted into D-psicose by immobilized D-psicose epimerase nanospheres to obtain D-fructose and D-alpha Mixed sugar solution of ketose;

[0064] (2) Pretreatment of the mixed sugar solution: dilute the mixed solution of D-fructose and D-psicose with water to a sugar content of 10%, vacuum filter with a 0.45 μm filter membrane to remove impurities, and then pass through a granular carbon chromatographic column. Decolorization pretreatment to obtain mixed sugar liquid raw materials;

[0065] (3) Sequential simulated moving bed separation: such as figure 1 As shown, the pretreated mixed sugar solution is separated by sequential simulated moving bed chromatography equipment, and the equipment is distributed by a rotary valve with 12 inlets and 13 outlets, and 8 ring-connected adsorption separation Column and 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com