Preparation of composite double-functional perovskite material with joint thermoluminescence and photoluminescence properties

A technology of thermoluminescence and photoluminescence, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of high power consumption and high cost of use, and achieve the effect of avoiding high temperature process, reducing defect density and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

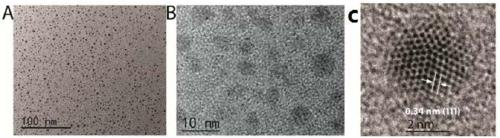

[0025] Preparation of perovskite quantum dot materials: SnI 2 (DMSO) prepared 1.0M precursor solution in diphenyl ether solution, mixed with 1ml oleylamine and heated to 250°C, under nitrogen protection, injected CsBr diphenyl ether solution (0.5M concentration) into the solution at a speed of 1ul / s. Close the reaction system, keep heating for 1h, add absolute ethanol / ether system after the reaction is cooled, centrifuge to obtain a solid, and vacuum dry for 1h to finally obtain the perovskite quantum dot material CsSn 2 I 4 Br.

[0026] Preparation of surface-modified thermoluminescent crystals: a-A 2 o 3 : After C crystal and graphene quantum dot alcohol solvent are mixed at a mass ratio of 10:1, add 2ml of methanesulfonic acid, place in a hydrothermal reaction kettle, heat at 120°C, and react for 4 hours to form a milky black liquid, then oscillate with microwave 1h, using nanofiltration to obtain modified thermoluminescent crystal Graphene@a-A 2 o 3 :C.

[0027] The...

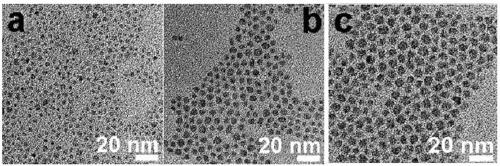

example 2

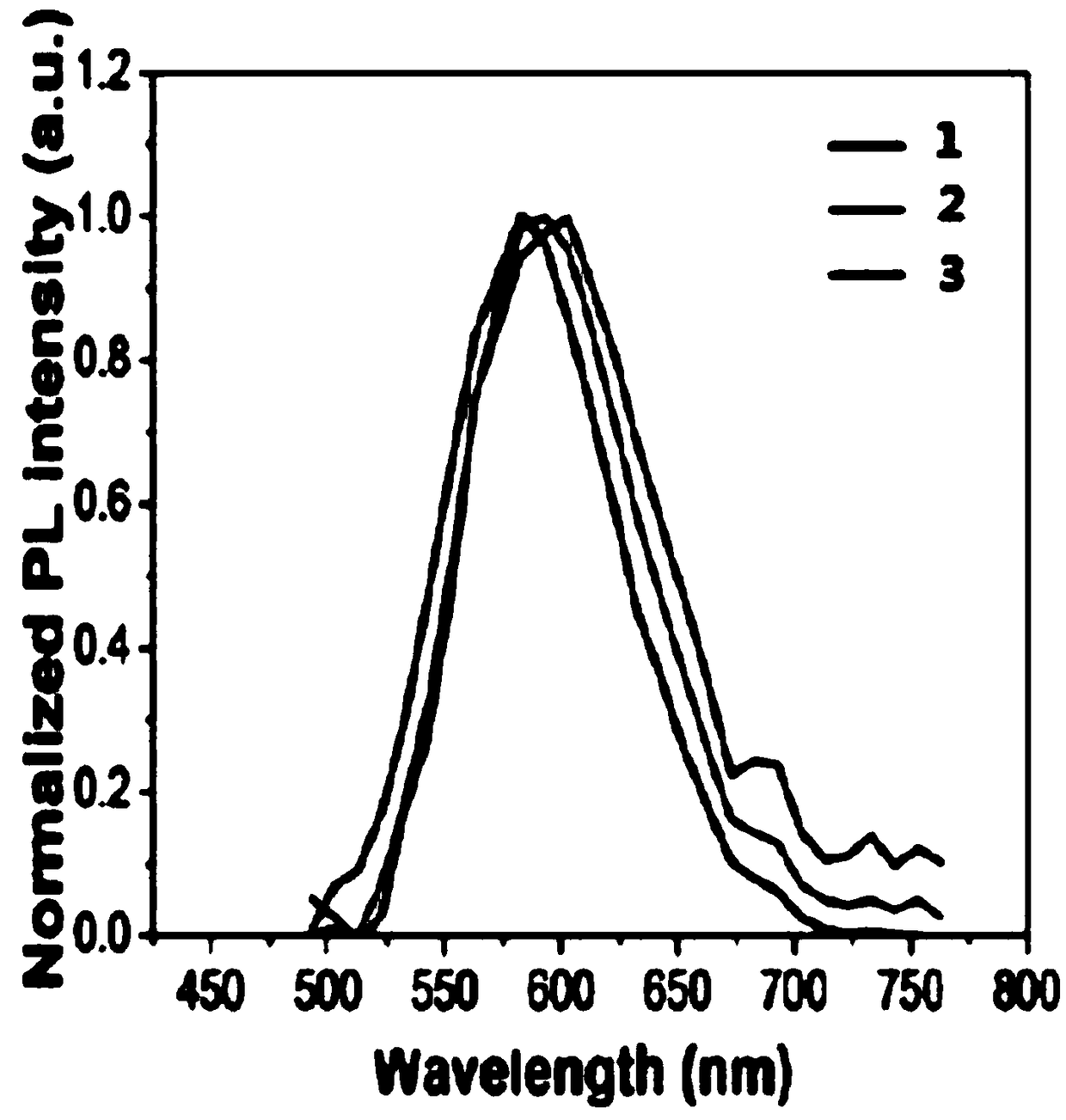

[0029] Preparation of perovskite quantum dot materials: SnBr 2 with TiCl 4 According to the mass ratio of 6:1, it was dissolved in 1,3-dimethyl-imidazolinone solution to prepare a 1.5M precursor solution, heated to 180 degrees, and under the protection of nitrogen, CH 3 NH 2 The diphenyl ether solution of Br (concentration 1M) was injected into the closed reaction system at a rate of 1 ul / s, and the heating was continued for 4 hours. After the reaction was cooled, an anhydrous ethanol / ether system was added to centrifuge to obtain a solid, and the perovskite was finally obtained by vacuum drying for 1 hour. Quantum dot materials (CH 3 NH 2 )SnTi 0.5 Br 3 CI 2 .

[0030] Preparation of surface-modified thermoluminescent crystals: HfO 2 After mixing crystals with phytic acid and triphenylphosphine at a mass ratio of 20:0.5:0.5, add 2ml of pyrrolidone, place in a hydrothermal reaction kettle, heat at 120°C, and react for 2 hours to form a milky liquid, then oscillate with...

example 3

[0033] Preparation of perovskite quantum dot materials: Pb(AcO) 2 , Ga 2 o 3 with ErNO 3 According to the mass ratio of 3:0.5:0.1, dissolve in HI solution to prepare 1.5M precursor solution, heat to 220 degrees, under nitrogen protection, CH 3 NH 2Br and LiCl are mixed and dissolved in diphenyl ether (concentration: 1.5M) at a ratio of 1:1, injected into a closed reaction system at a speed of 2ul / s, heated continuously for 2h, and added to anhydrous ethanol / ether system after cooling to obtain solid, vacuum dried for 1h to finally obtain the perovskite quantum dot material (CH 3 NH 2 ) 0.5 Li 0.5 Pb 0.83 Ga 0.14 Er 0.3 I 3 CI.

[0034] Preparation of surface-modified thermoluminescent crystals: mix AlN:Ta crystals with graphdiyne (Graphdiyne) at a mass ratio of 20:1, add 2ml of pyrrolidone, place in a hydrothermal reactor, heat at 160°C, react for 2 hours, and become milky The liquid was then subjected to microwave oscillation for 1 h, and then nanofiltration was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com