Multicolor luminous carbon quantum dot as well as preparation method and application thereof

A carbon quantum dot and mass ratio technology, applied in the field of multi-color luminescent carbon quantum dots and their preparation, can solve the problems of difficult separation operation, rare preparation of controllable multi-color carbon quantum dots, complicated equipment requirements, etc. The effect of short time, high yield, easy operation and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a method for preparing multicolor luminescent carbon quantum dots, the method comprising steps:

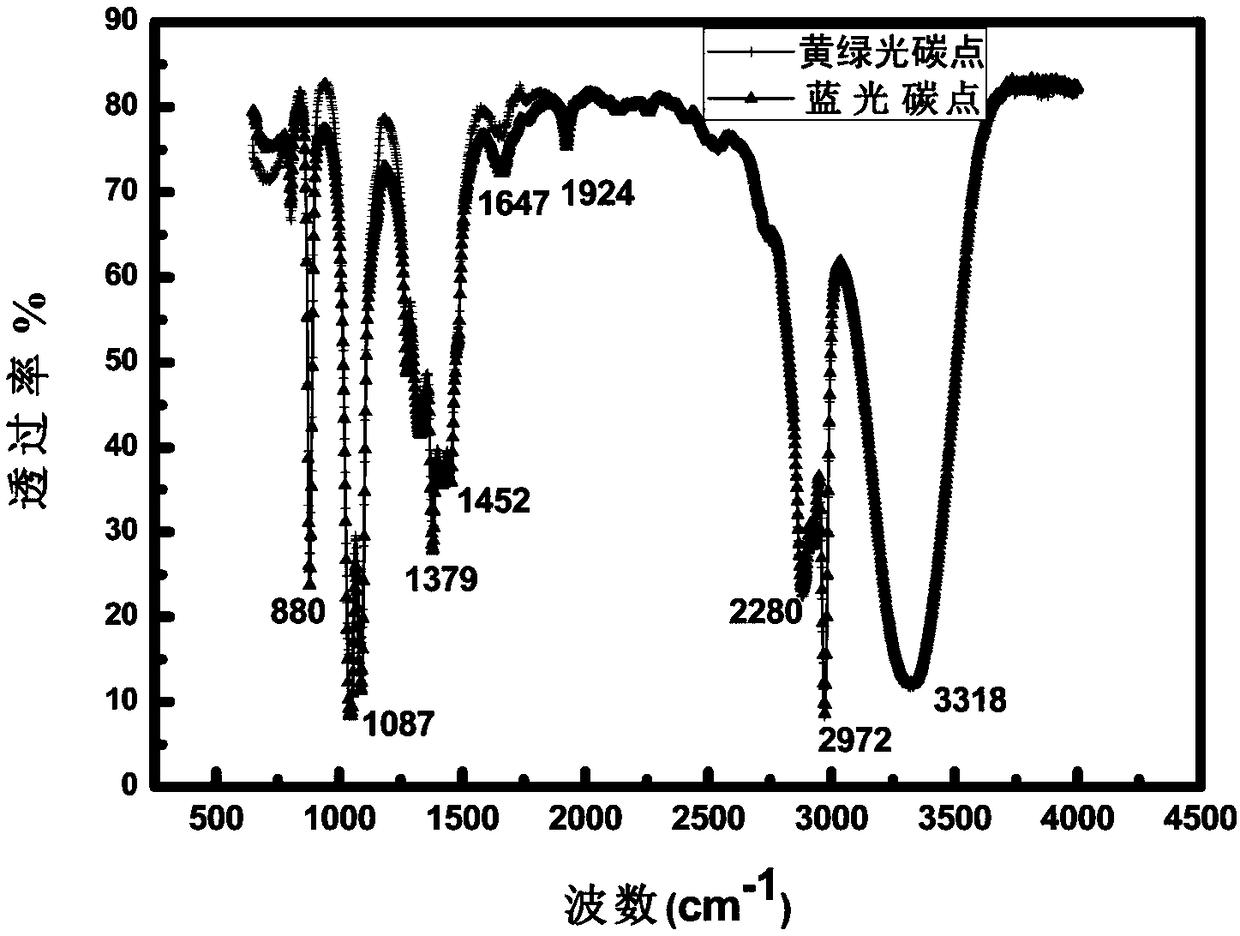

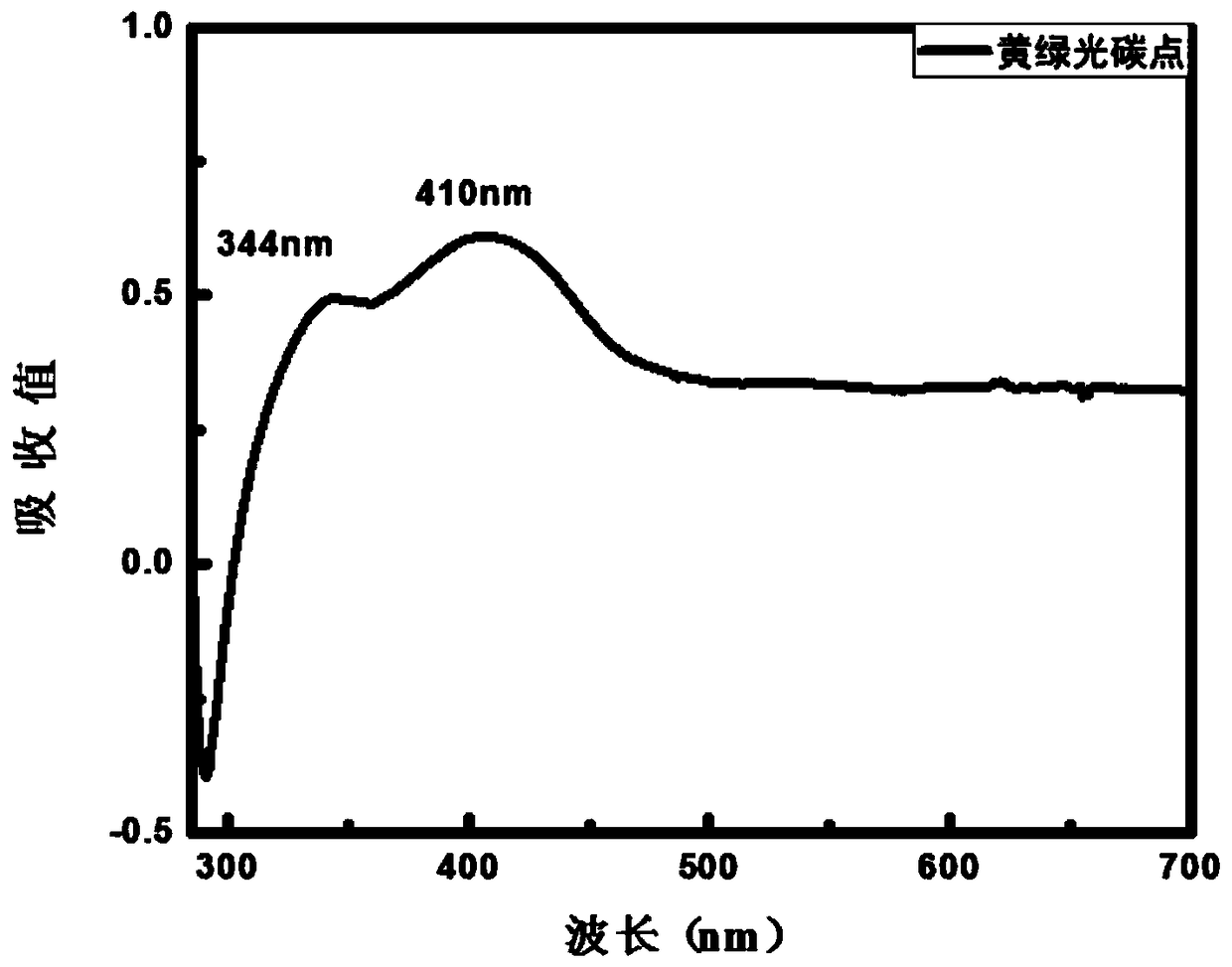

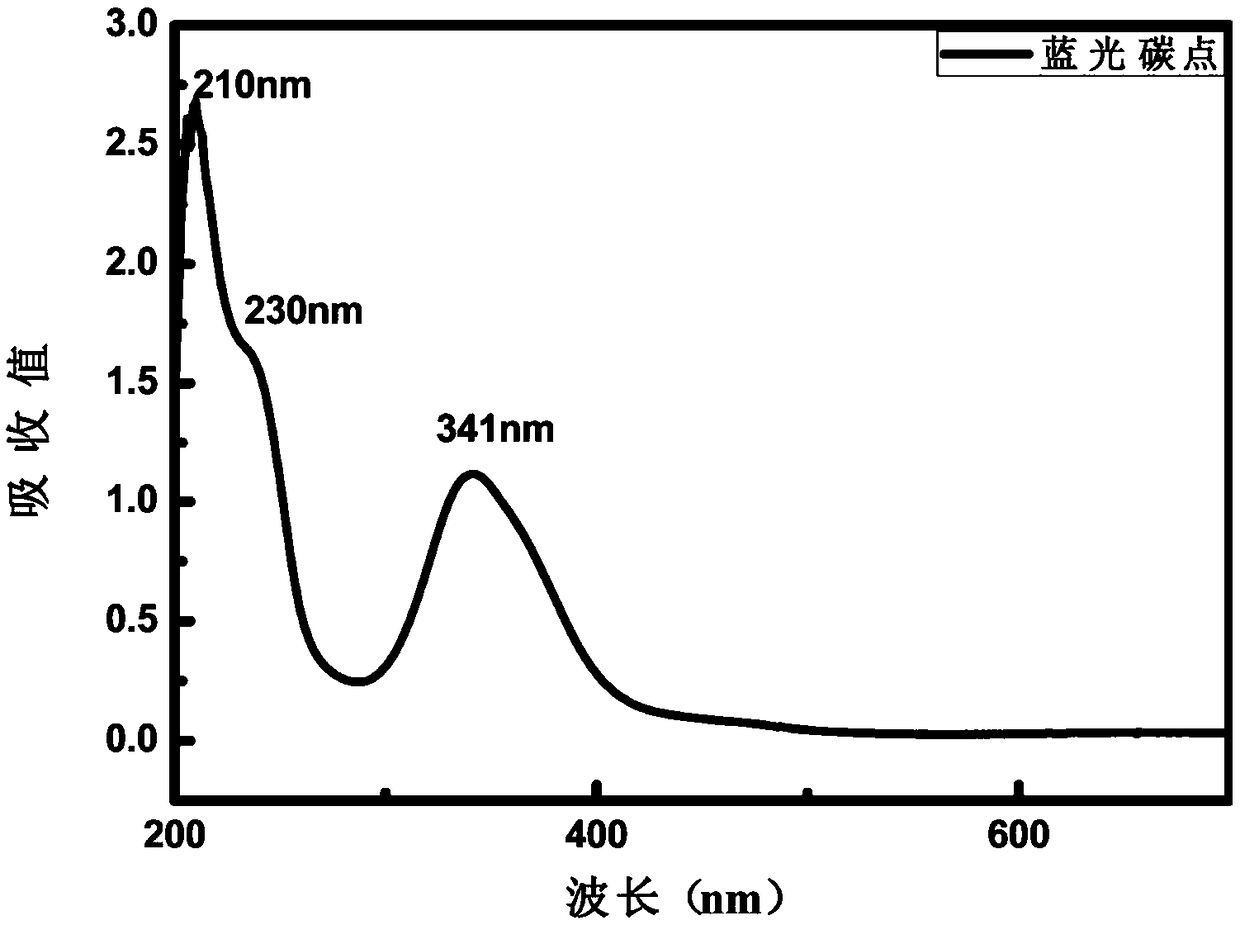

[0033] Dissolve 3g of citric acid, 3g of oxalic acid and 3g of urea in 24ml of deionized water and mix it with 3g of polyethylene glycol, place it in a hydrothermal reaction kettle and tighten it, place the hydrothermal reaction kettle in an oven and heat it to 180°C, keep the temperature constant After reacting for 4 hours, let it cool down to room temperature, take out the obtained solution, add deionized water and pour it into the centrifuge, adjust the centrifuge speed to 4000r / min, set the time to 10min, centrifuge three times to obtain the centrifugal precipitate, and then The centrifuged precipitate obtained was mixed with ethanol and then centrifuged again three times. The obtained upper liquid was dried in a vacuum oven at 60°C for 60 minutes to obtain carbon quantum dots with an emission peak at 525nm and yellow-green light. The obtained pr...

Embodiment 2

[0036] This embodiment provides a method for preparing multicolor luminescent carbon quantum dots, the method comprising steps:

[0037] Dissolve 3g of citric acid and 6g of urea in 36ml of water and mix it with 15g of polyethylene glycol, then put it in a hydrothermal reaction kettle and tighten it, put the hydrothermal reaction kettle in an oven and heat it to 200°C, react at a constant temperature for 12 hours and then let it stand Cool to room temperature, take out the obtained solution, add deionized water and pour it into the centrifuge, adjust the speed of the centrifuge to 4000r / min, set the time to 10min, centrifuge three times and separate to obtain the centrifugal precipitate, and then the obtained centrifugal precipitate After adding ethanol and mixing evenly, centrifuge again three times. The obtained upper liquid was dried in a vacuum oven at 60°C for 60 minutes to obtain yellow-green light emitting carbon quantum dots. The obtained precipitate was air-dried under...

Embodiment 3

[0039] This embodiment provides a method for preparing multicolor luminescent carbon quantum dots, the method comprising steps:

[0040] Dissolve 3g of citric acid, 6g of oxalic acid and 6g of urea in 30ml of deionized water and mix it with 30g of polyethylene glycol, then place it in a hydrothermal reaction kettle and tighten it. Put the hydrothermal reaction kettle in an oven and heat it to 120°C. After reacting for 8 hours, let it cool down to room temperature, take out the obtained solution, add deionized water and pour it into the centrifuge, adjust the centrifuge speed to 4000r / min, set the time to 10min, centrifuge three times to obtain the centrifugal precipitate, and then The centrifuged precipitate obtained was mixed with ethanol and then centrifuged again three times. The obtained upper liquid was dried in a vacuum oven at 50°C for 60 minutes to obtain carbon quantum dots emitting yellow-green light. The obtained precipitate was air-dried under natural conditions to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com