Magnesium, erbium and ytterbium doped sodium niobate, preparation method and application thereof

A technology of sodium niobate and magnesium erbium ytterbium, which is applied in the field of magnesium erbium ytterbium tri-doped sodium niobate and its preparation, can solve problems such as low luminous intensity, achieve simple preparation process, improve up-conversion luminous intensity, and improve up-conversion luminous intensity. The effect of rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides a magnesium-erbium-ytterbium-tridoped sodium niobate, which is prepared by the following preparation method.

[0034] 1. Weigh 0.2712mmol of ytterbium nitrate pentahydrate, 0.0904mmol of erbium nitrate pentahydrate and 0.01mol of magnesium chloride hexahydrate and dissolve them in 40ml of deionized water in sequence.

[0035] 2. Weigh 0.15mol sodium hydroxide and dissolve it in the mixed solution in step 1, add 40mL ethylene glycol and mix well.

[0036] 3. Slowly add 0.0049 mol of niobium pentoxide to the mixed solution in step 2, stir evenly, then move to the reaction kettle at 270°C for 24 hours.

[0037] 4. After the reaction, the mixed solution in the reactor was filtered, and the obtained solid powder was dried at 80° C. for 8 hours.

[0038] 5. Finally, the powder sample was calcined at 1050° C. for 2 hours.

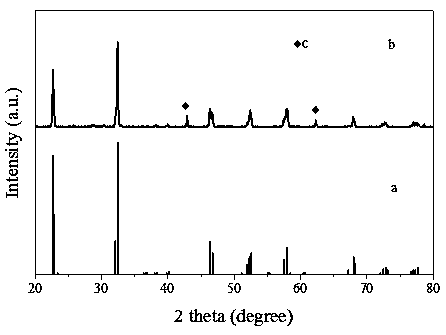

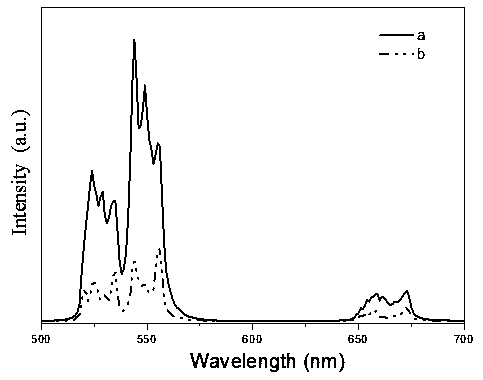

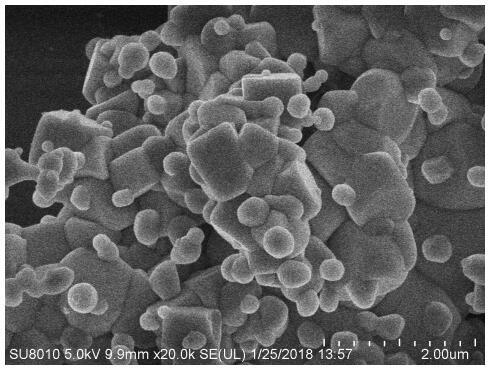

[0039] figure 1 It is the XRD figure of the magnesium erbium ytterbium tri-doped sodium niobate prepared in the present embodim...

Embodiment 2

[0042] This embodiment provides a magnesium erbium ytterbium tridoped sodium niobate. Its preparation method is basically consistent with the method in Example 1, and the difference is that the total amount of ytterbium nitrate pentahydrate in step 1 is 0.2719mmol, and the total amount of erbium nitrate pentahydrate is 0.0755mmol; in step 3, the total amount of niobium pentoxide is 0.0049 mol. The performance of the magnesium erbium ytterbium tridoped sodium niobate prepared by this method is similar to that of Example 1.

Embodiment 3

[0044] This embodiment provides a magnesium erbium ytterbium tridoped sodium niobate. Its preparation method is basically consistent with the method in embodiment 1, and difference is: the total amount of ytterbium nitrate pentahydrate in step 1 is 0.154mmol, and the total amount of erbium nitrate pentahydrate is 0.0924mmol; In step 3, the total amount of niobium pentoxide is 0.0051mol.

[0045] The performance of the magnesium erbium ytterbium tridoped sodium niobate prepared by this method is similar to that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com