Lubricating grease and preparation method thereof

A technology of lubricating grease and lubricating base oil, applied in the field of lubricating grease, can solve problems such as the inability to meet high temperature lubrication, and achieve the effect of excellent water resistance and excellent high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

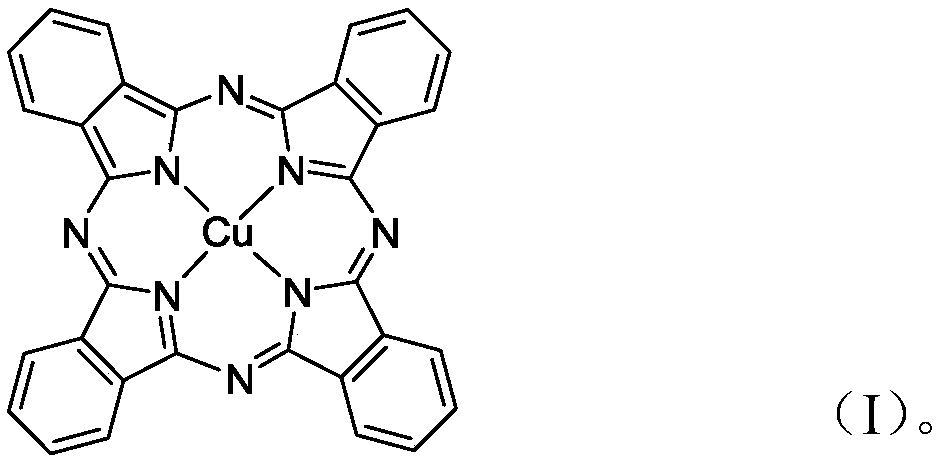

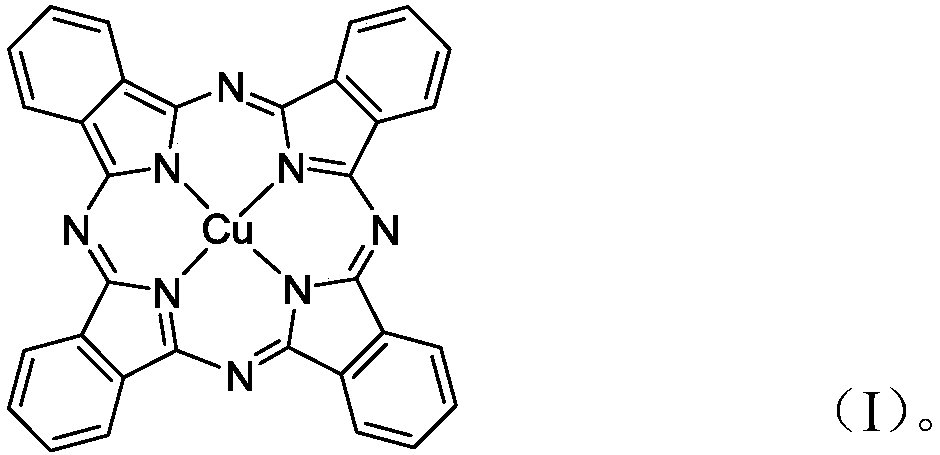

Image

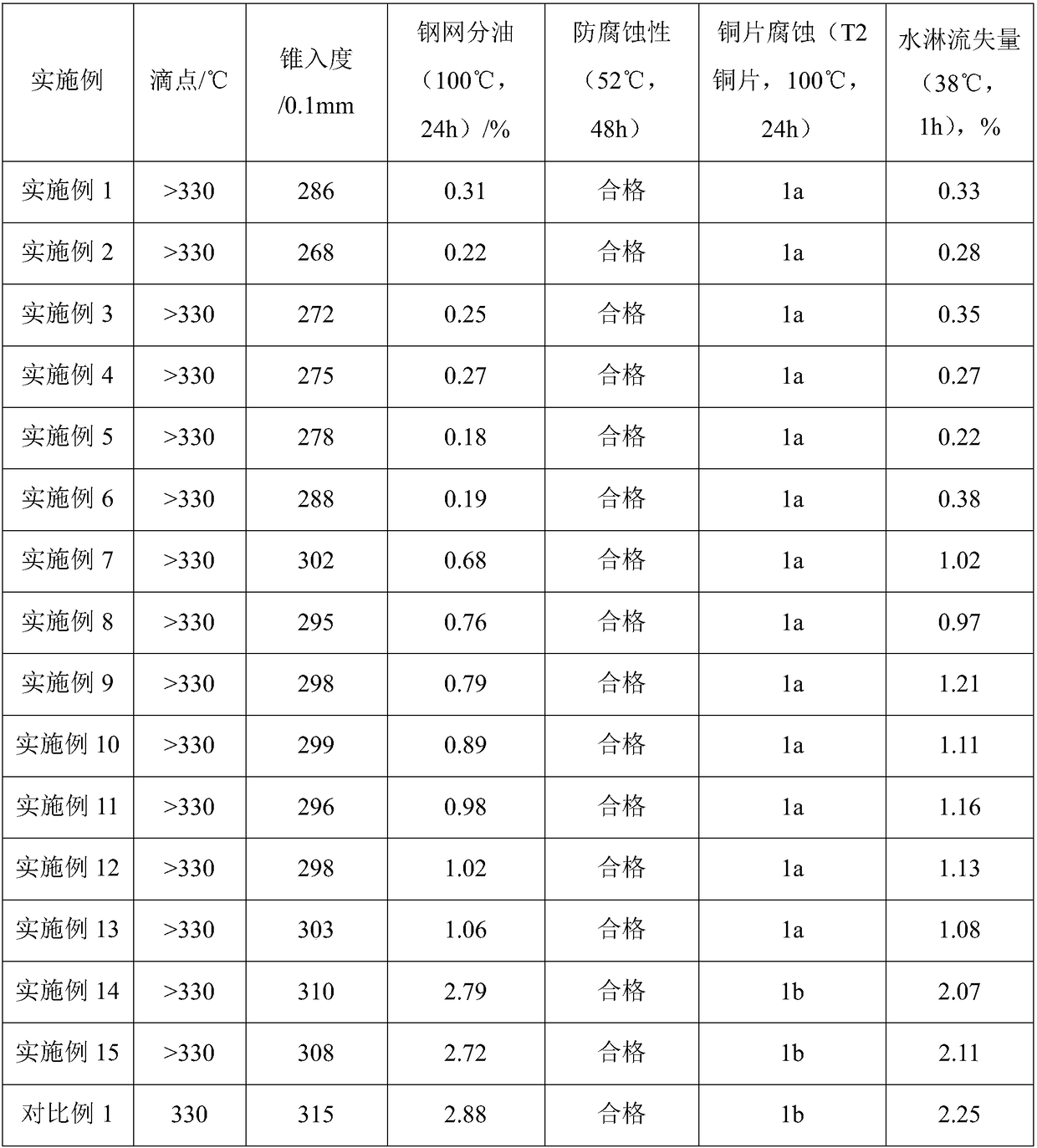

Examples

Embodiment 1

[0031] Raw material components: 150BS base oil (kinematic viscosity at 100°C is 31mm 2 / s, flash point is 288°C) 80kg; copper phthalocyanine 10kg; silica gel (average particle size 0.5μm) 5kg; diphenylamine 5kg.

[0032] Stir the base oil and copper phthalocyanine evenly at room temperature, add silica gel and continue to stir, heat up to 60°C and keep stirring for 10 minutes, then add diphenylamine, continue to stir and cool to room temperature, and grind 3 times with a grinder to obtain this example Prepared lubricating grease, test its product properties are listed in Table 1.

Embodiment 2

[0034] Raw material components: polyalphaolefin oil PAO10 (kinematic viscosity at 100°C is 10mm 2 / s, flash point is 290°C) 74kg; copper phthalocyanine 24kg; silica gel (average particle size is 10μm) 1kg; N-phenyl-α-naphthylamine 1kg.

[0035] Stir the base oil and copper phthalocyanine evenly at room temperature, add silica gel and continue stirring, heat up to 80°C and keep stirring for 20 minutes, then add N-phenyl-α-naphthylamine, continue stirring and cool to room temperature, grind 3 times through a grinder , to obtain the lubricating grease prepared in this embodiment, and its product properties were tested and listed in Table 1.

Embodiment 3

[0037] Raw material components: mixed oil of 500N base oil and methyl silicone oil 201-100 (kinematic viscosity at 100°C is 15mm 2 / s, flash point is 280°C) 79kg; copper phthalocyanine 20kg; silica gel (average particle size 50μm) 0.5kg; N-phenyl-α-naphthylamine 0.5kg.

[0038] Stir the base oil and copper phthalocyanine evenly at room temperature, add silica gel and continue stirring, heat up to 65°C and keep stirring for 30 minutes, then add N-phenyl-α-naphthylamine, continue stirring and cool to room temperature, grind 3 times through a grinder , to obtain the lubricating grease prepared in this embodiment, and its product properties were tested and listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com