Processing technology for improving bending performance of tab copper strip

A processing technology and technology for copper strips, which are applied in the field of processing technology to improve the bending performance of tab copper strips, can solve problems such as the inability to apply copper strip production technology, and achieve the advantages of overcoming uneven annealing, uniform product performance and consistent heat flow direction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

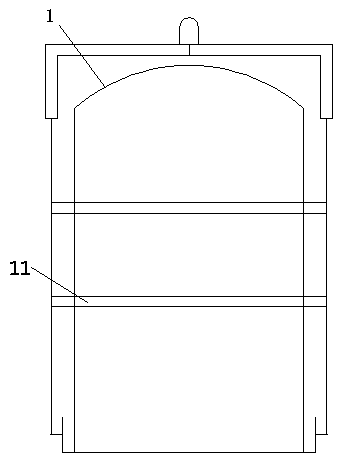

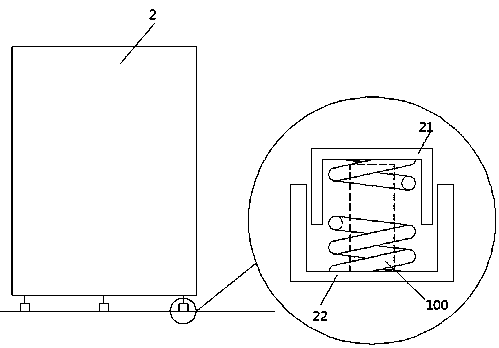

Image

Examples

Embodiment 1

[0043] The invention provides a processing technology for improving the bending performance of tab copper strips. Through the process, tab copper strips with Vickers hardness of 50-55HV and bending times ≥ 7 can be obtained, and the copper content is >99.95%. Phosphorus Content≤0.003%, iron content≤0.005%, lead content≤0.005%.

[0044] A processing technology for improving the bending performance of a tab copper strip, comprising the following steps: (1) smelting and drawing → (2) hot rolling → (3) milling → (4) rough rolling → (5) trimming → ( 6) Primary annealing → (7) Primary cleaning → (8) Intermediate rolling → (9) Secondary annealing → (10) Secondary cleaning → (11) Finish rolling → (12) Air cushion furnace annealing cleaning → (13) Stretch bending Straightening → (14) Slitting and delivery.

[0045] Step (1) Smelting and drawing casting: use cathodic electrolytic copper with a purity >99.9% as raw material to ensure the purity of copper, and control the phosphorus cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com