Fabricated combined soil nailing wall with recoverable flexible surface layer and construction method

A composite soil nailing and flexible surface technology, which is applied in excavation, sheet pile walls, foundation structure engineering, etc., can solve problems such as the lack of tight connection between the concrete surface layer and part of the soil layer, low construction efficiency, and large concrete consumption. , to achieve the effect of shortening the spraying and curing age, saving construction costs and reducing material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

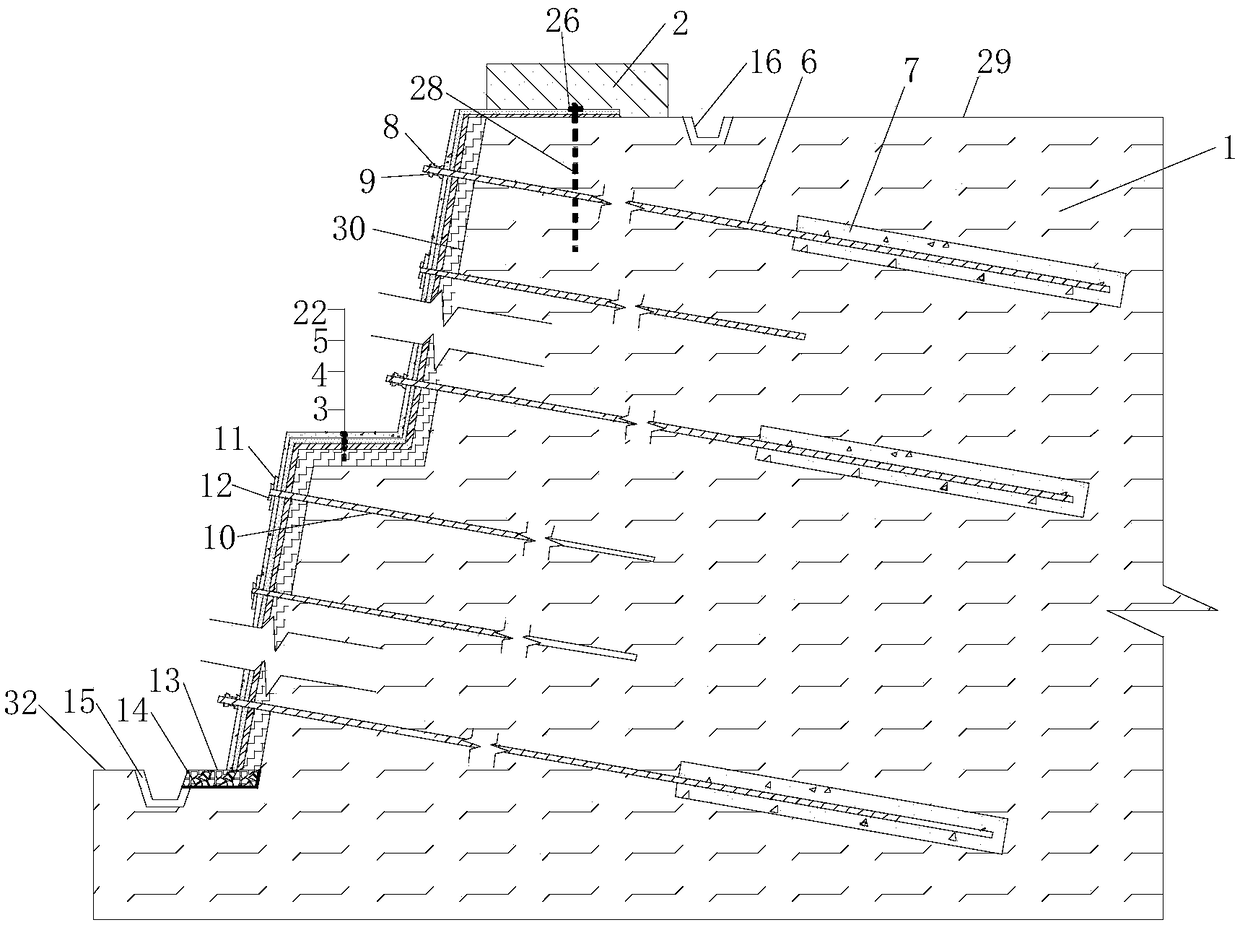

[0043] combined with figure 1 As shown, the recyclable composite soil nail wall of an assembled flexible surface layer that the present invention relates to comprises a foundation pit surrounded by inclined pit walls 30, the bottom of the foundation pit is provided with a water collection ditch 15, and the bottom of the foundation pit is located at the bottom of the water collection Between the ditch 15 and the pit wall 30, a water-repelling film 14 and a gravel drainage ditch 13 are laid, the obliquely recoverable anchor rods 6 and soil nails 10 on the pit wall 30, and the top surface 29 of the foundation pit is evenly arranged along the pit wall 30. The vertical recoverable anchor rods 28 are 2 m to 2.5 m away from the pit wall, and the distance between adjacent vertical recoverable anchor rods 28 is 2 m. A hydrophobic layer 3 , a waterproof geomembrane 4 , a geogrid 5 and a concrete fireproof layer 22 are sequentially constructed on the pit wall 30 . Wherein, the hydrophob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com