Dual-fuel engine combustion organization method using high-pressure natural gas injection valve

A dual-fuel engine, natural gas technology, applied in combustion engines, internal combustion piston engines, engine control and other directions, can solve problems such as poor power performance, economical emissions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

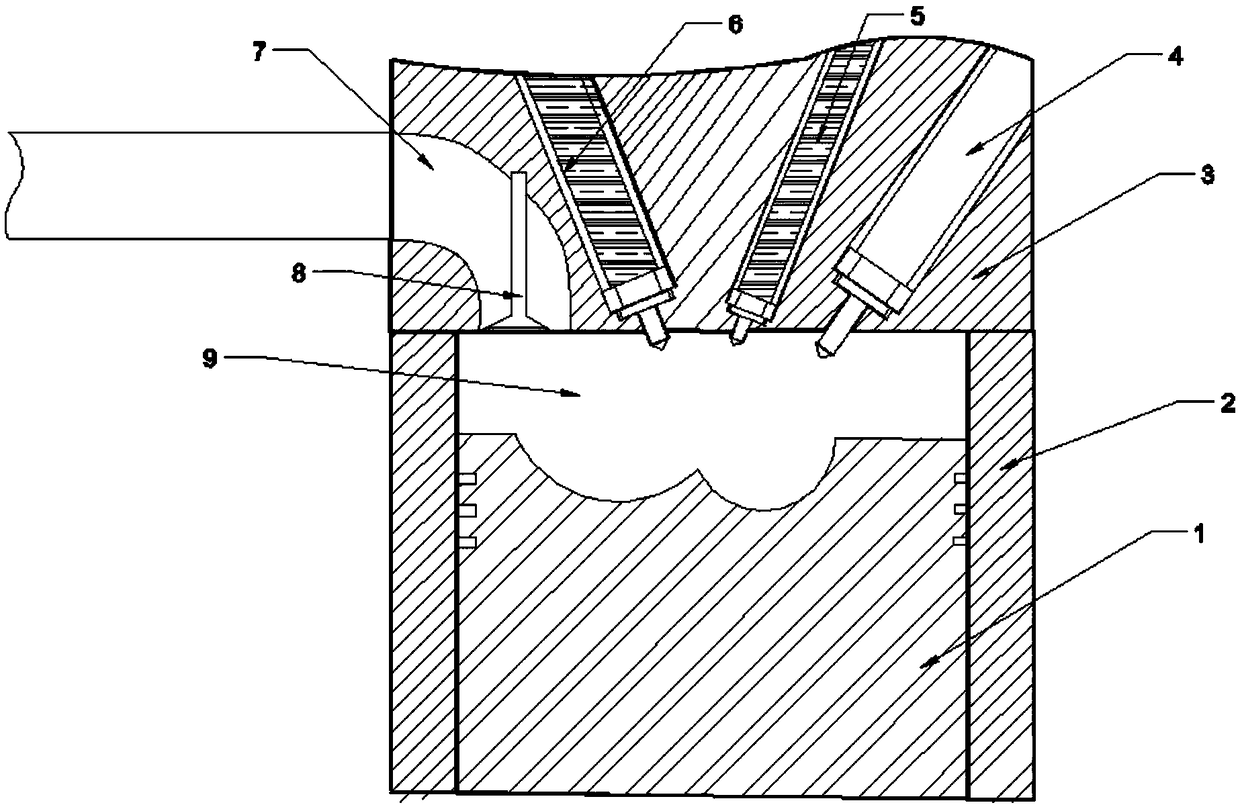

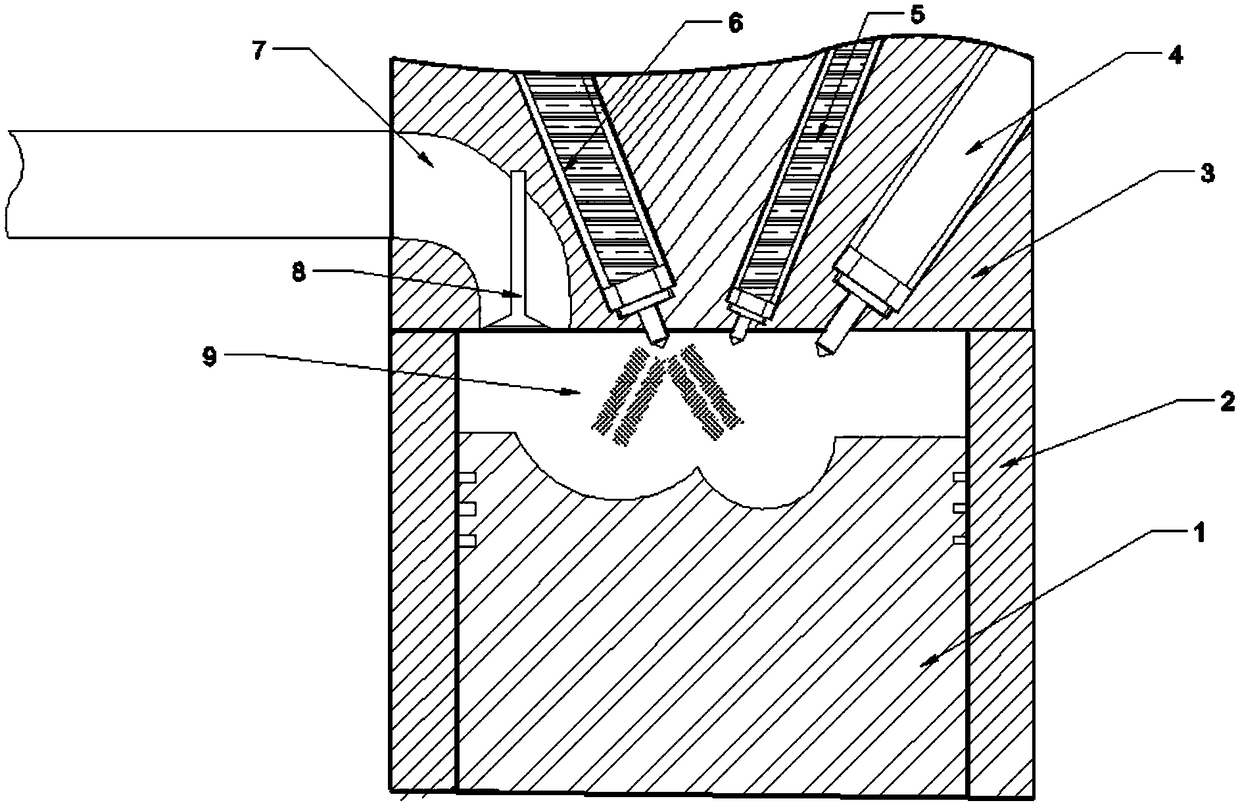

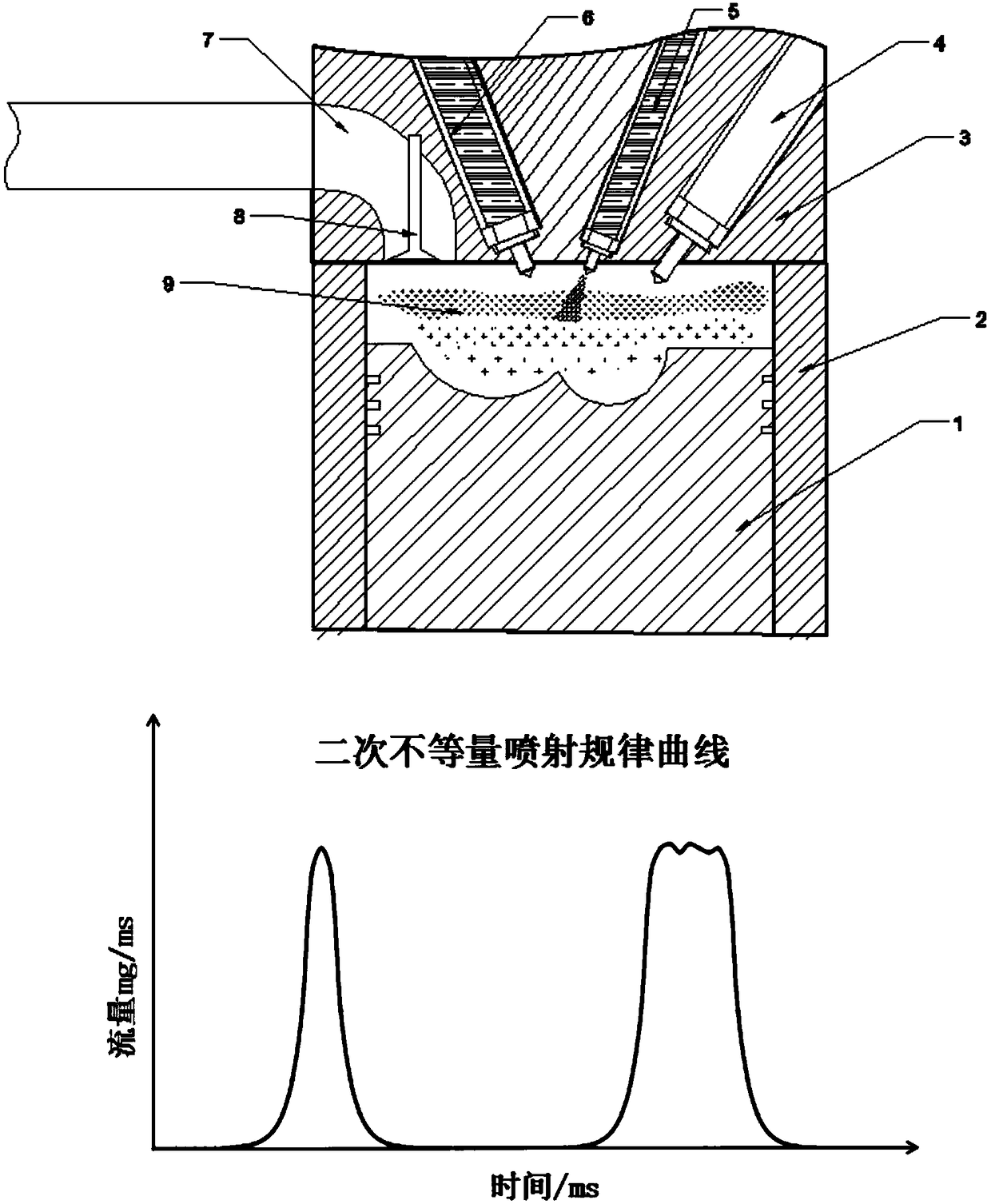

[0022] A dual-fuel engine combustion organization method using high-pressure natural gas injection valves, with four operating modes:

[0023] Mode 1. When the dual-fuel engine starts, the idle speed and the load are lower than 15%, the engine is in the fuel oil operation mode, the high-pressure natural gas injection valve and the auxiliary injector do not work, from the closing of the intake valve to the piston traveling 10- 30°CA, only use the main fuel injector to inject a single injection into the cylinder, because natural gas is prone to misfire due to lean combustion at low load;

[0024] Mode 2. When the dual-fuel engine is at 15-50% low-medium load, the engine is running in gas mode. From the closing of the intake valve to 30°CA before the piston travels to the top dead center, the high-pressure natural gas injection valve performs two non-stop injections to the combustion chamber. Equal amount of natural gas injection, at the same time when the piston travels to 15-25...

Embodiment example 2

[0031] The invention belongs to the field of internal combustion engine combustion methods, and in particular relates to a dual-fuel engine combustion organization method and a combustion system composition using main and auxiliary injectors and high-pressure multiple injections in a natural gas cylinder.

[0032] Compared with other types of engines, dual-fuel engines have obvious advantages in terms of economy of use, thermal efficiency, combustion noise, NOx and PM emissions, etc.; Knocking is prone to occur under load, the increase of natural gas substitution rate is limited, and there are problems such as high HC and CO emissions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com