Yawing force solid fuel gas generator

A gas generator, lateral force technology, applied in jet propulsion, machine/engine, rocket engine, etc., can solve the problems of easy sticking of steering gear, impact damage residue, large impact force, etc., to reduce solid phase Granular, stable and reliable work, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further explained below through specific embodiments and accompanying drawings.

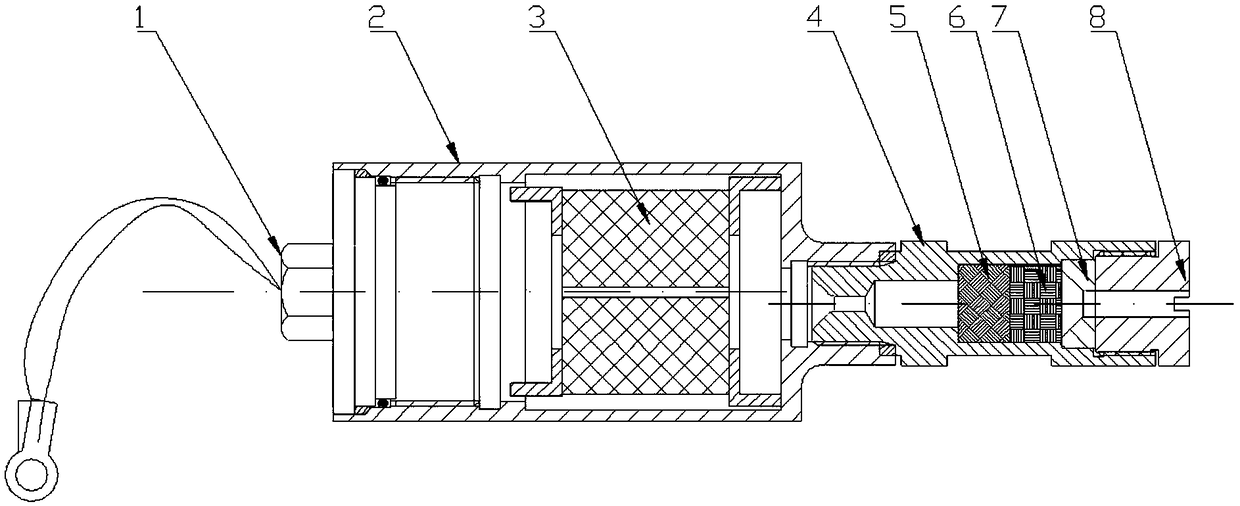

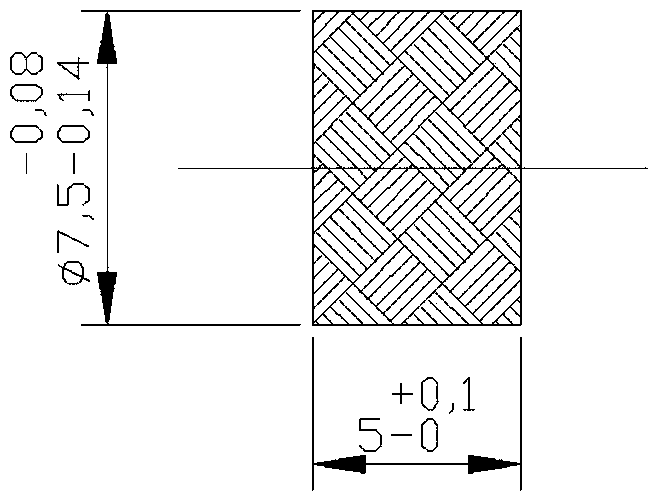

[0018] Such as figure 1 , In this lateral force gas generator, the igniter 1 is threadedly connected with the combustion chamber 2, and a double-layer sealing structure of a copper gasket and an ○-ring is used. The combustion chamber 2 and the gas pipeline 4 are threadedly connected and sealed with copper gaskets. Charge 3 is freely filled in the combustion chamber, and is fixed by an ignition bracket and a drug baffle. The gas pipeline 4 is made of 1Cr17Ni2 material, and the inlet is designed with a throat. The combustion pressure, combustion speed and gas flow of the charge 3 are controlled through the diameter of the throat. Filter screen 6, pressure ring 7, and the outlet end is processed with external interface thread; the primary filter screen 5 is wound with molybdenum wire with a diameter of Φ0.25mm and molded into a cylindrical structure. The outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com