A self-balancing pressure regulating valve pressure regulating hydraulic system and its control method

A technology of hydraulic system and pressure regulating valve, which is applied in the direction of fluid pressure actuation system components, valve operation/release device, valve device, etc., which can solve the problem of low economy and efficiency of test operation, prolonged test preparation time, and waste of gas source and other problems, to achieve the effect of convenient control, simple and reliable operation, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

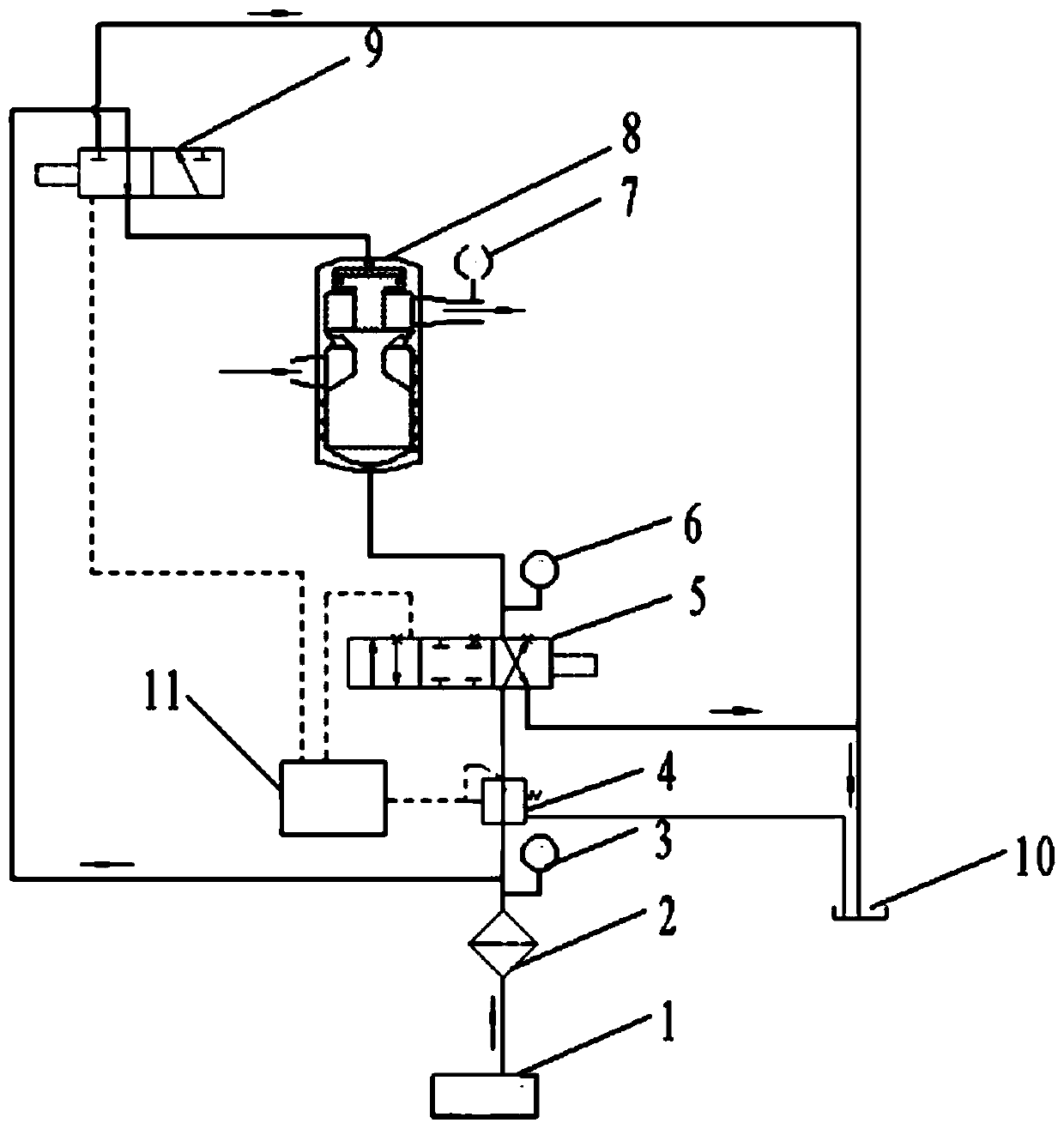

[0026] refer to figure 1 , shows a structural schematic diagram of a pressure regulating hydraulic system of a self-balancing pressure regulating valve provided by an embodiment of the present invention.

[0027] Such as figure 1 As shown, the pressure regulating hydraulic system of the self-balancing pressure regulating valve may include: hydraulic station 1, electro-hydraulic proportional pressure reducing valve 4, electro-hydraulic servo valve 5, self-balancing pressure regulating valve 8, electromagnetic reversing valve 9, programmable logic Controller 11 and fuel tank 10.

[0028] The connection relationship of each part in the pressure regulating hydraulic system is as follows:

[0029] Such as figure 1 As shown, one end of the hydraulic station 1 is connected to one end of the electro-hydraulic proportional pressure reducing valve 4, the other end of the electro-hydraulic proportional pressure reducing valve 4 is connected to one end of the electro-hydraulic servo va...

Embodiment 2

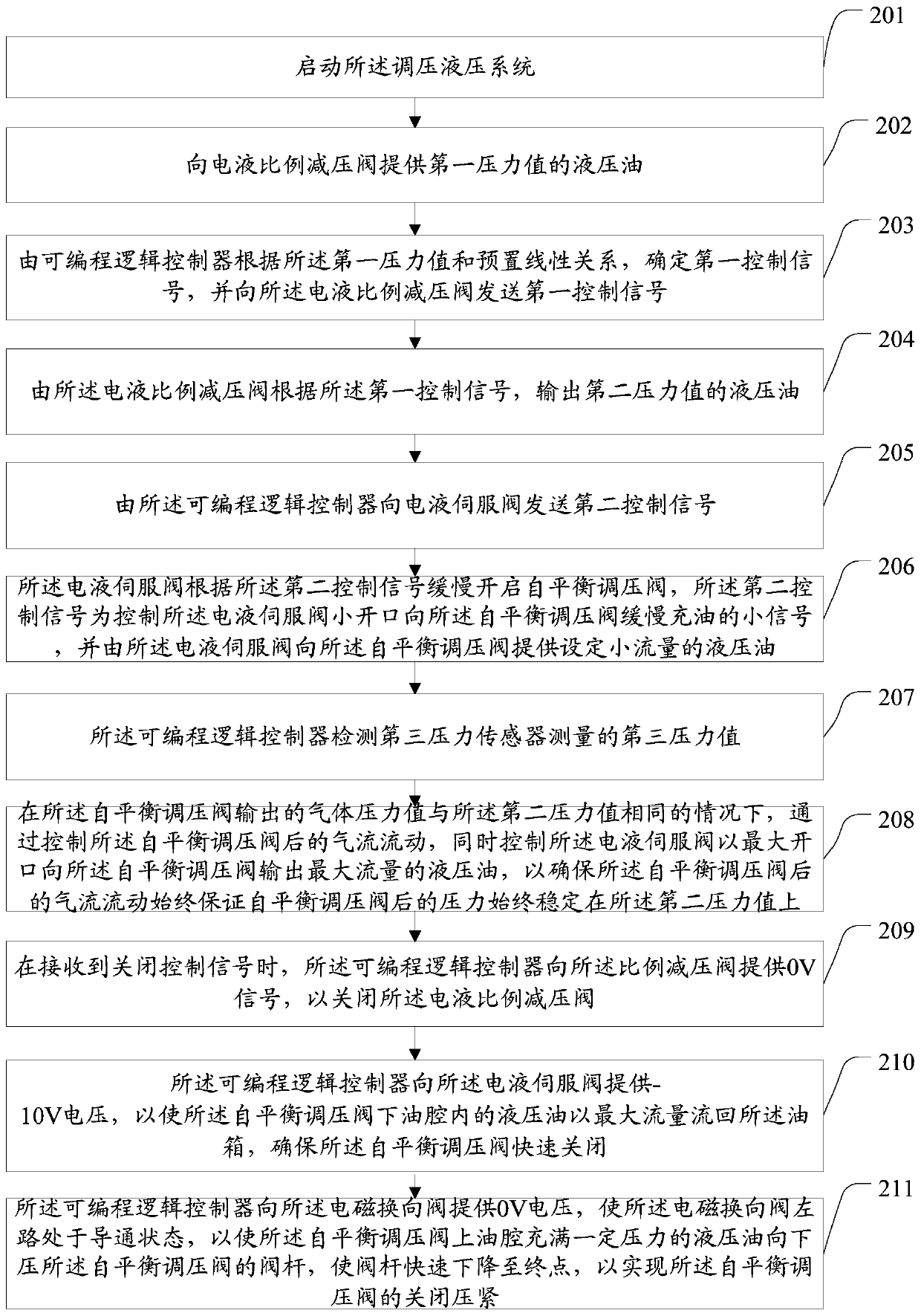

[0051] refer to figure 2 , shows a flow chart of the steps of a self-balancing pressure regulating valve pressure regulating control method provided by an embodiment of the present invention, the self-balancing pressure regulating valve pressure regulating control method can be applied to any one of the first embodiment above The pressure regulating hydraulic system described above may specifically include the following steps:

[0052] Step 201: Start the pressure regulating hydraulic system.

[0053] The embodiments of the present invention can be applied to the scene of rapid and accurate pressure regulation of a self-balancing pressure regulating valve of high-pressure airflow in a hypersonic wind tunnel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com