Resonant accelerometer based on bident type resonant beam

A technology of accelerometer and resonant beam, which is applied in the direction of measuring acceleration, speed/acceleration/impact measurement, measuring device, etc. It can solve the problem of reducing measurement sensitivity and achieve the effect of high detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

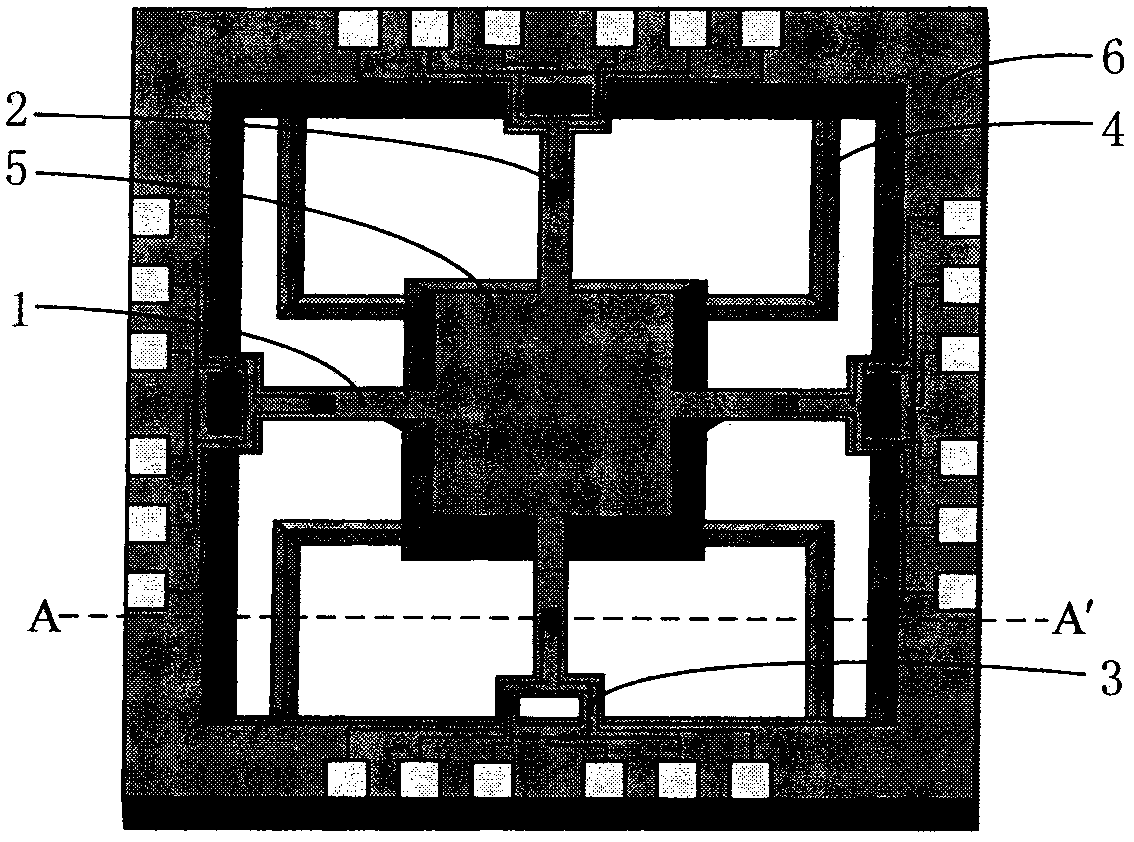

Method used

Image

Examples

Embodiment 1

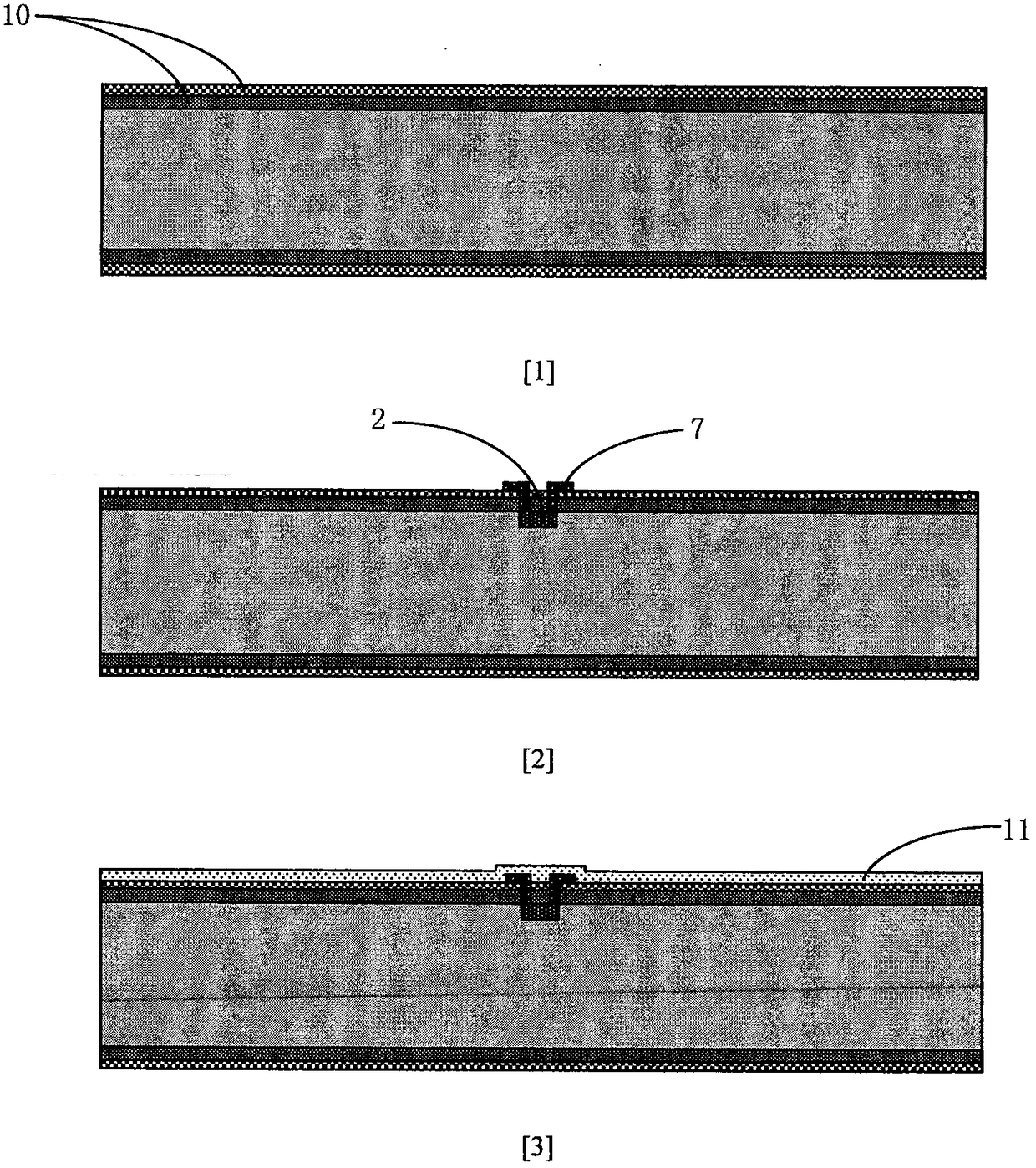

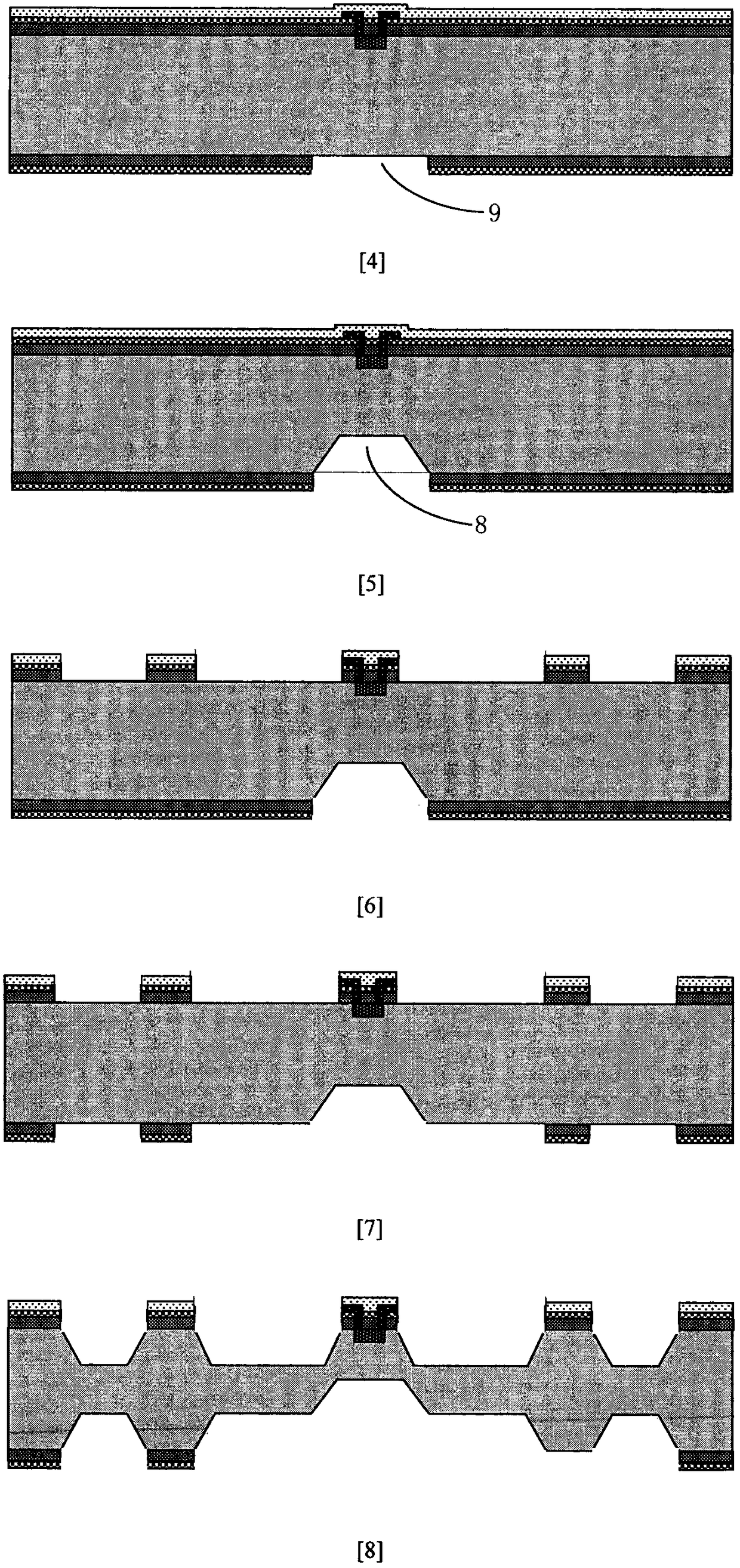

[0028] Embodiment 1: The thickness of the original silicon wafer is 389 microns, the thickness of the double-pronged fork-shaped resonant beam (1) is 3 microns, the thickness of the crab-leg support beam (4) is 25 microns, and the width of the corrosion groove (8) is 660 microns. The production process determined based on the above data is as follows:

[0029] 1) The original silicon wafer is (100) double-sided polished silicon wafer with a thickness of 389 microns. Thermal oxidation, a silicon dioxide film with a thickness of 0.6 microns is produced on the front and back sides of the silicon wafer in the (100) crystal orientation, and a silicon nitride film with a thickness of 0.3 microns is produced on the front and back sides of the silicon wafer by low-pressure chemical vapor deposition. (See figure 2 [1])

[0030] 2) Combining photolithography, corrosion, and doping processes to fabricate the excitation resistor (2) and piezoresistor (3) of the double-pronged fork-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com