Integrated high power beam combiner

A beam combiner and high-power technology, which is applied in the field of fiber laser and high-power beam combiner devices, can solve the problems of increasing the volume and loss of fiber lasers, and achieve the effects of commercial production, high reliability and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

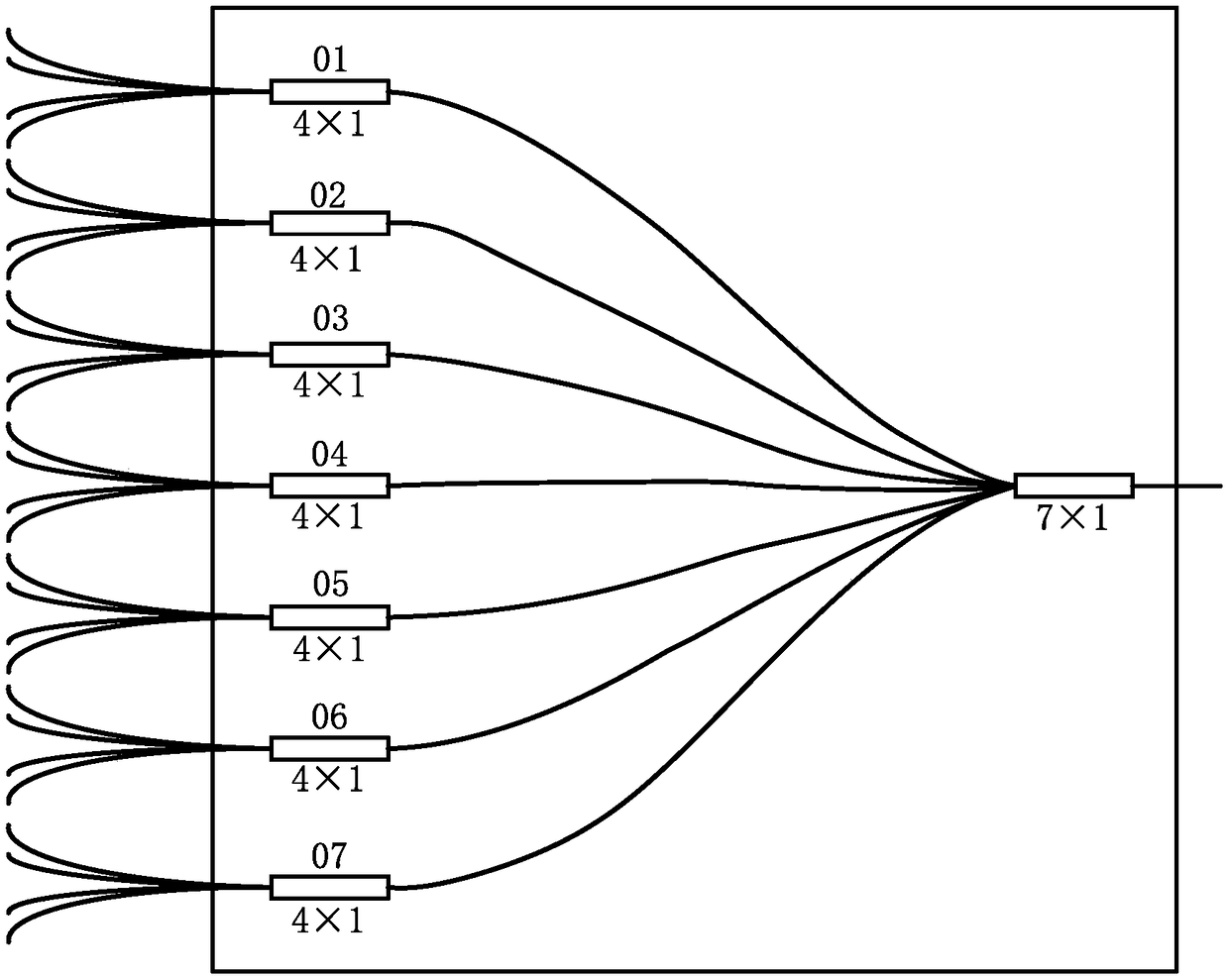

[0026] Integrated high power beam combiner for pump coupling of high power fiber lasers. Such as figure 1 shown.

[0027] Beam combiner A selects 4×1 beam combiner, a total of 7, the input fiber is 105 / 125μm single-clad fiber, the numerical aperture NA. is 0.15, and the output fiber diameter is 200 / 220μm single-clad Optical fiber, the numerical aperture NA. is 0.22, the withstand power of a single arm is not lower than 100W, and the transmittance is not lower than 97%.

[0028] The beam combiner B is a 7×1 beam combiner, the input fiber is the same as the output fiber of the beam combiner A, the fiber diameter is 200 / 220 μm, the numerical aperture NA. is 0.22, and the single-arm transmittance is not less than 95%.

[0029] The output pigtail is a double-clad fiber with a diameter of 20 / 400μm and a numerical aperture NA. of 0.06 / 0.46.

[0030] It is used for the coupling of 915nm or 975nm wavelength semiconductor lasers. The output power of each semiconductor laser is calcul...

Embodiment 2

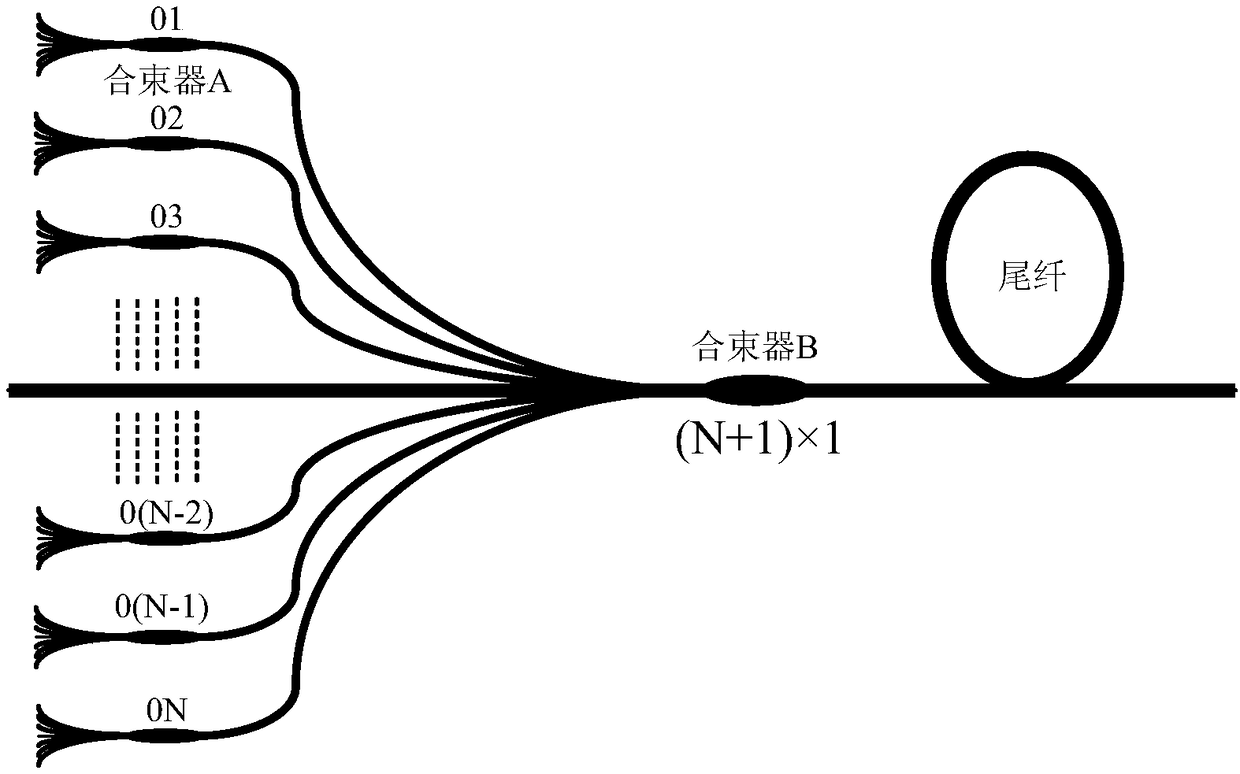

[0032] Integrated High Power Combiner for Pump Coupling of High Power Fiber Amplifiers

[0033] Beam combiner A selects 7×1 beam combiner, a total of 6, the input fiber is 105 / 125μm single-clad fiber, the numerical aperture NA. is 0.15, and the output fiber diameter is 220 / 242μm single-clad Layer fiber, the numerical aperture NA. is 0.22, the withstand power of a single arm is not less than 100W, and the transmittance is not less than 92%.

[0034] Beam combiner B is a (6+1)×1 type beam combiner, the input fiber is the same as the output fiber of beam combiner A, the fiber diameter is 220 / 242μm, the numerical aperture NA. is 0.22, and the single-arm transmittance is not less than 95%.

[0035] The output pigtail is a double-clad fiber with a diameter of 20 / 400μm and a numerical aperture NA. of 0.06 / 0.46.

[0036] It is used for the coupling of 915nm or 975nm wavelength semiconductor lasers. The output power of each semiconductor laser is calculated as 100W, and the pump powe...

Embodiment 3

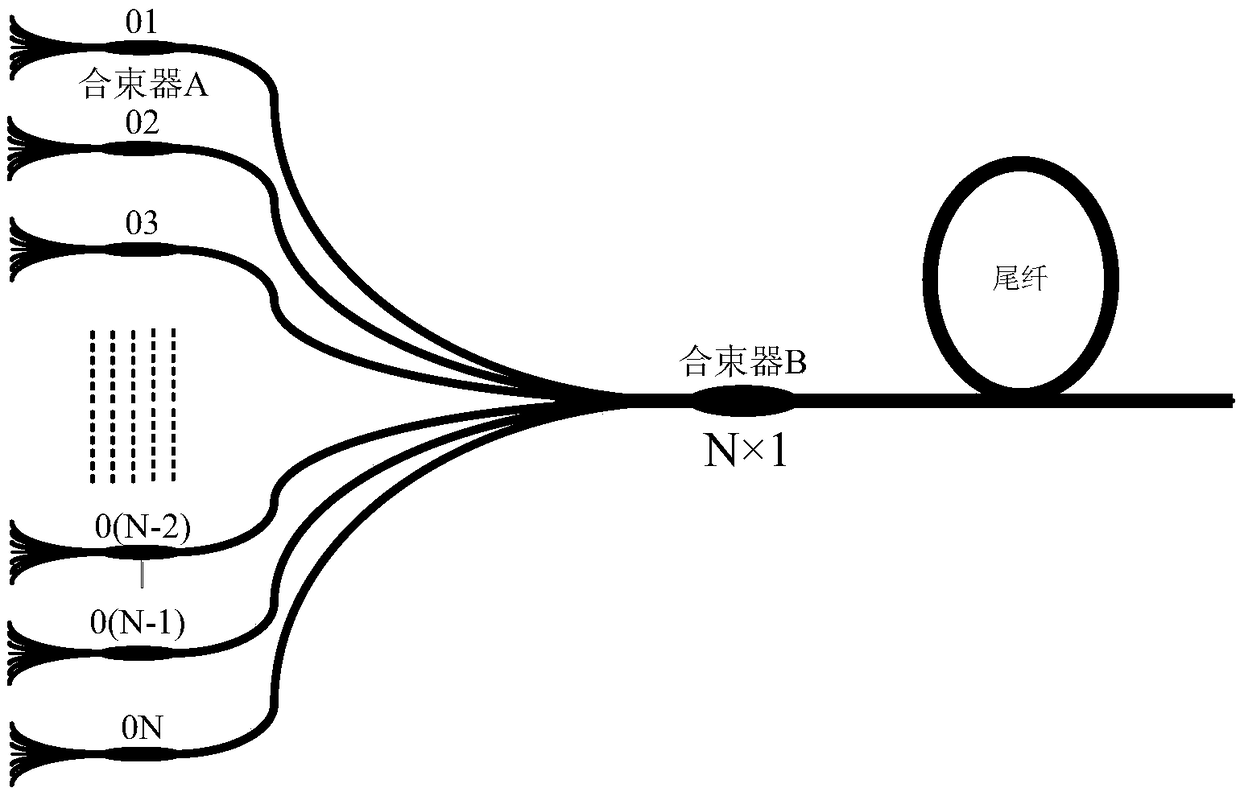

[0038] Integrated high power beam combiner for cascaded pumped high power fiber lasers

[0039] The beam combiner A is a 7×1 beam combiner, a total of 6, the input fiber is a 10 / 130μm double-clad fiber, the numerical aperture NA. is 0.06 / 0.46, and the output fiber diameter is 105 / 125μm , the numerical aperture NA. is 0.15, the single-arm withstand power is not lower than 200W, and the transmittance is not lower than 97%.

[0040] Beam combiner 2 is a (6+1)×1 type beam combiner, the input fiber is the same as the output fiber of beam combiner A, the fiber diameter is 105 / 125 μm, the numerical aperture NA. is 0.15, and the single-arm transmittance is not less than 95%.

[0041] The output pigtail is a double-clad fiber with a diameter of 30 / 250μm and a numerical aperture NA. of 0.06 / 0.46.

[0042] It is used for the injection of 1018nm fiber laser as a cascaded pump source. The output power of each 1018nm fiber laser is calculated as 200W, and the pump power of about 1358W can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com