A high-power semiconductor laser based on PT Bragg reflection waveguide and a preparation method thereof

A Bragg reflection and semiconductor technology, which is applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve problems such as difficult coupling of light beams, complex manufacturing processes, and unstable laser beams, and achieve high COD thresholds. Improve injection efficiency, Good for heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

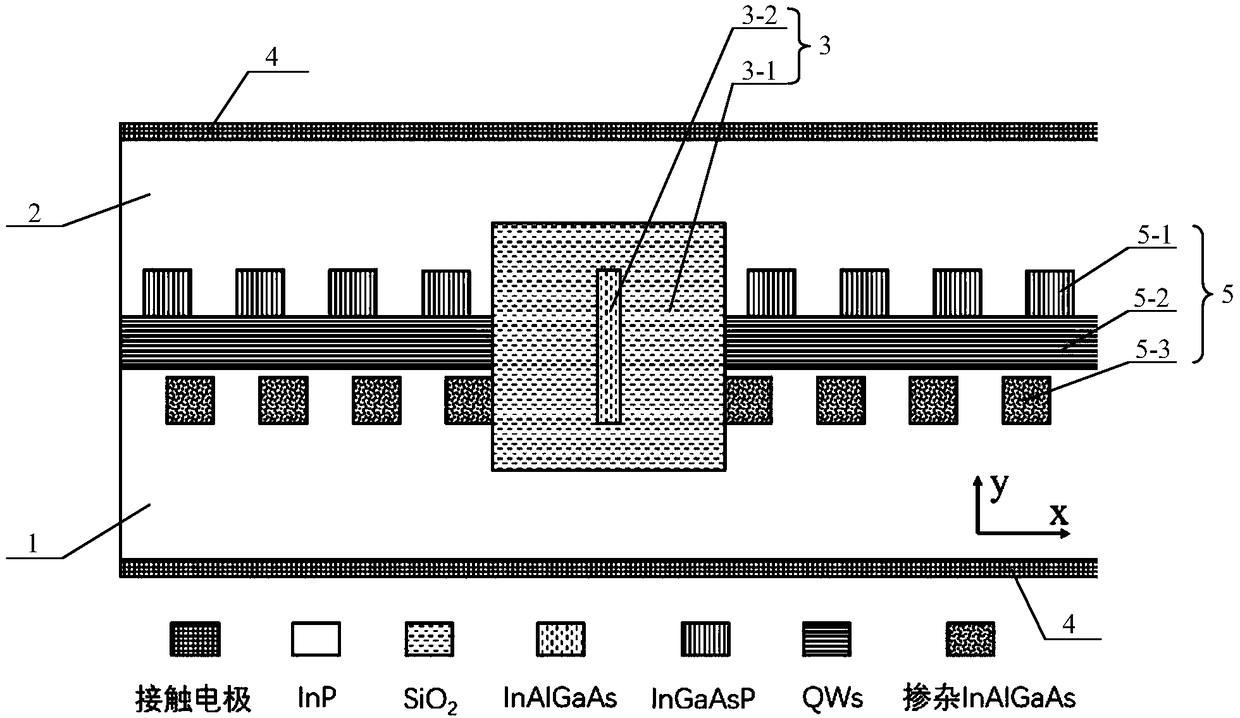

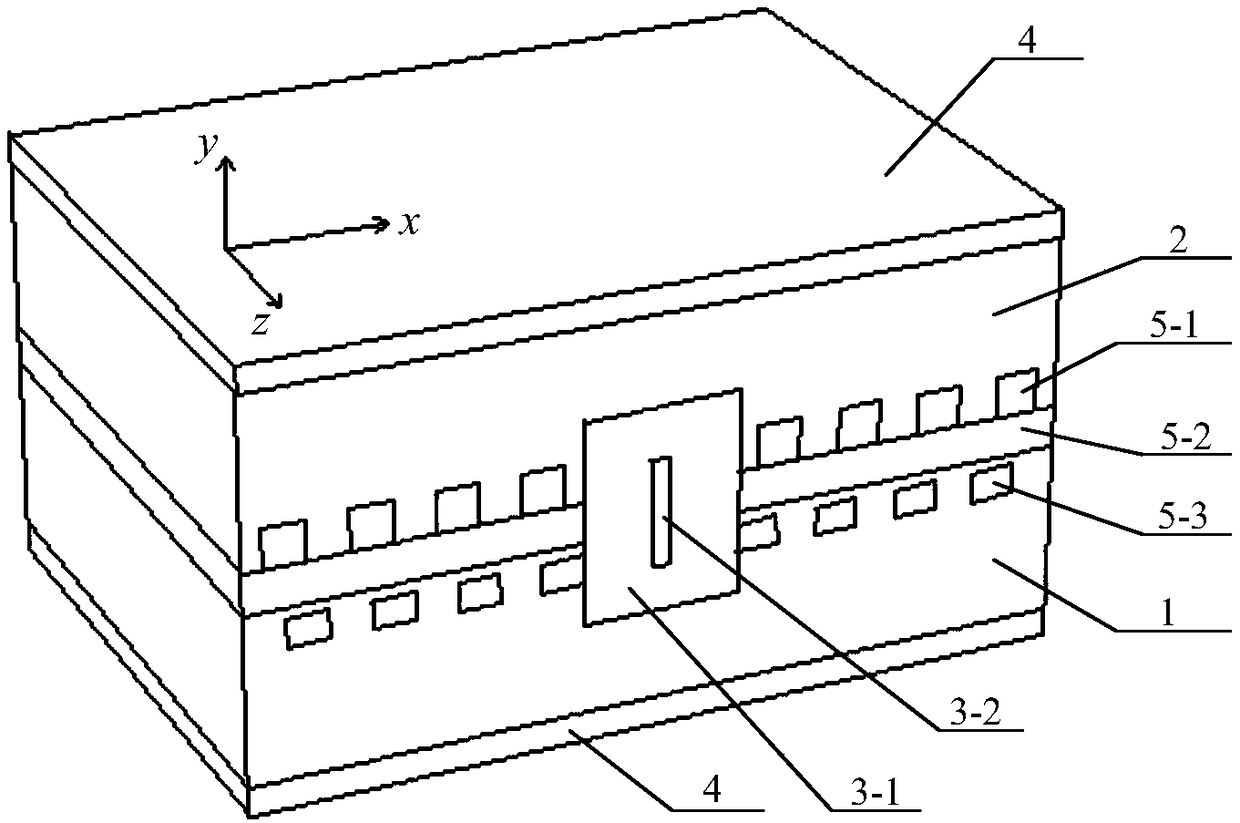

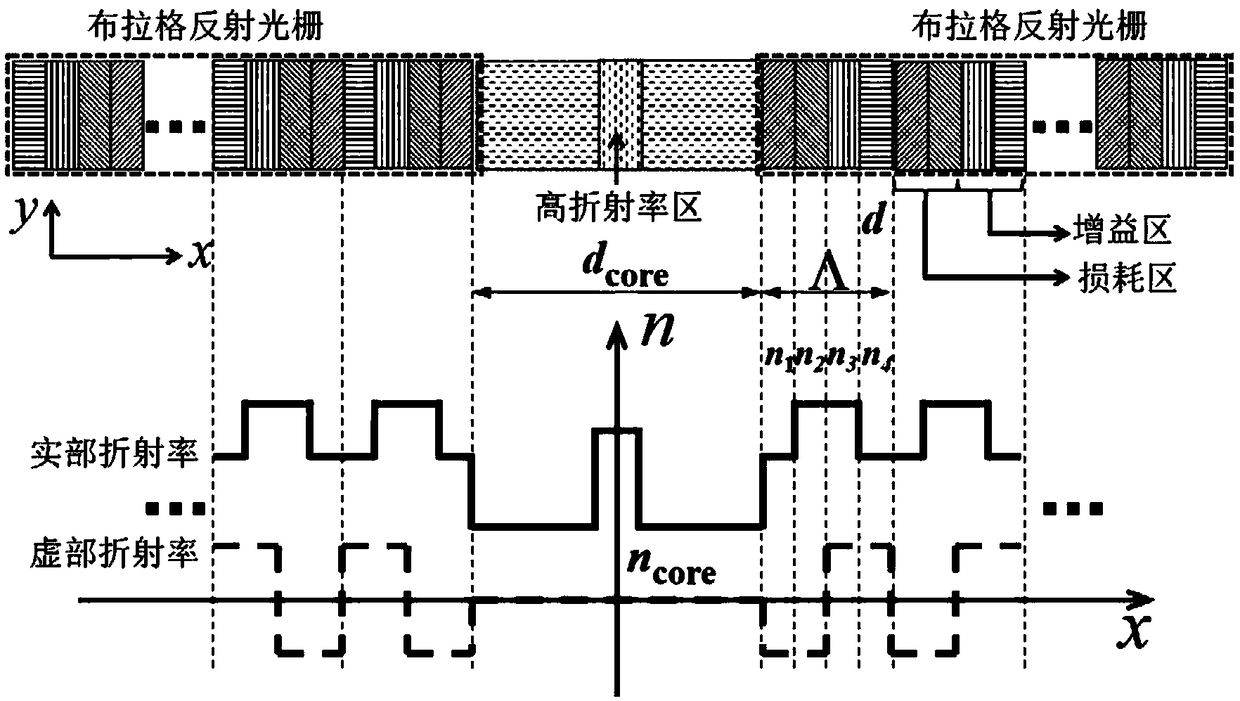

[0047] A high-power semiconductor laser based on PT Bragg reflective waveguide, such as figure 1 As shown, including InP substrate 1 and InP cladding layer 2, InP substrate 1 and InP cladding layer 2 are provided with a low refractive index central cavity 3 and PT Bragg reflection grating regions 5 located on both sides of the low refractive index central cavity 3, Both the low-refractive-index central cavity 3 and the PT Bragg reflection grating area 5 run through the entire z-axis, such as figure 2 shown;

[0048] The low-refractive-index central cavity 3 is formed by wrapping a high-refractive-index strip waveguide with a low-refractive-index material, and the PT Bragg reflection grating region 5 includes a quantum well structure.

Embodiment 2

[0050] A high-power semiconductor laser based on PT Bragg reflection waveguide, the structure is as shown in Embodiment 1, the difference is that the InP substrate 1 is the lower end face and the upper end face of the InP cladding layer 2 is provided with a contact electrode 4, such as figure 2 As shown, the upper and lower bottom surfaces in the y direction are the contact electrodes 4, from which the current is injected.

Embodiment 3

[0052] A high-power semiconductor laser based on PT Bragg reflection waveguide, the structure is as shown in embodiment 2, the difference is that the low refractive index central cavity 3 is made of SiO 2 The material 3-1 wraps the InAlGaAs strip waveguide 3-2, and the effective refractive index of the low-refractive index central cavity 3 is lower than that of the PT Bragg reflection grating regions on both sides.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com