Laser engraving machine cross-platform motion control system

A motion control system, laser engraving machine technology, applied in laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problem of unintuitive parameter display, and achieve the effect of avoiding misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

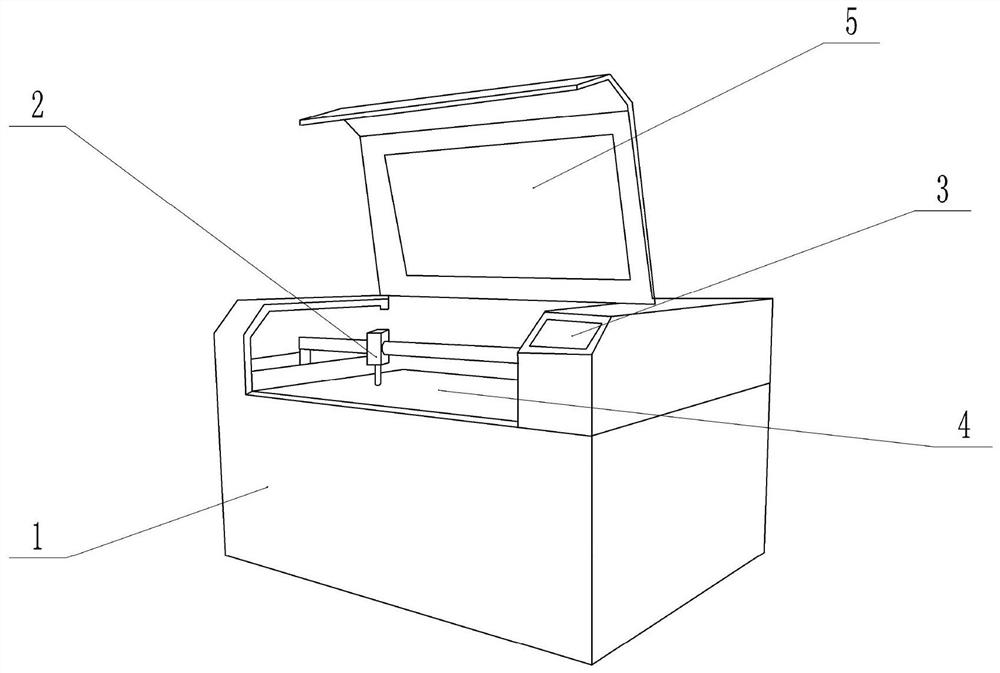

[0024] The embodiments are basically as attached. Figure 1 The cross-platform motion control system of laser engraving machine includes a server, a control terminal and a laser engraving machine. The server is respectively connected with the control terminal and the laser engraving machine through a wireless communication module. The wireless communication module includes a Bluetooth low-energy communication module (BLE) and a BCM43143 WIFI communication module.

[0025] The laser engraving machine comprises a machine body 1, an outer cover 5, a carbon dioxide laser 2, a photoelectric subsystem, a cooling subsystem, a plane table 4, a smoke exhaust subsystem, an alarm device and a control panel 3, wherein the control panel 3 is provided with keys and a display, and a motion control program is introduced into the control panel 3, and the control panel 3 can control the laser engraving machine to work according to the motion control program.

[0026] The server is composed of single...

Embodiment 2

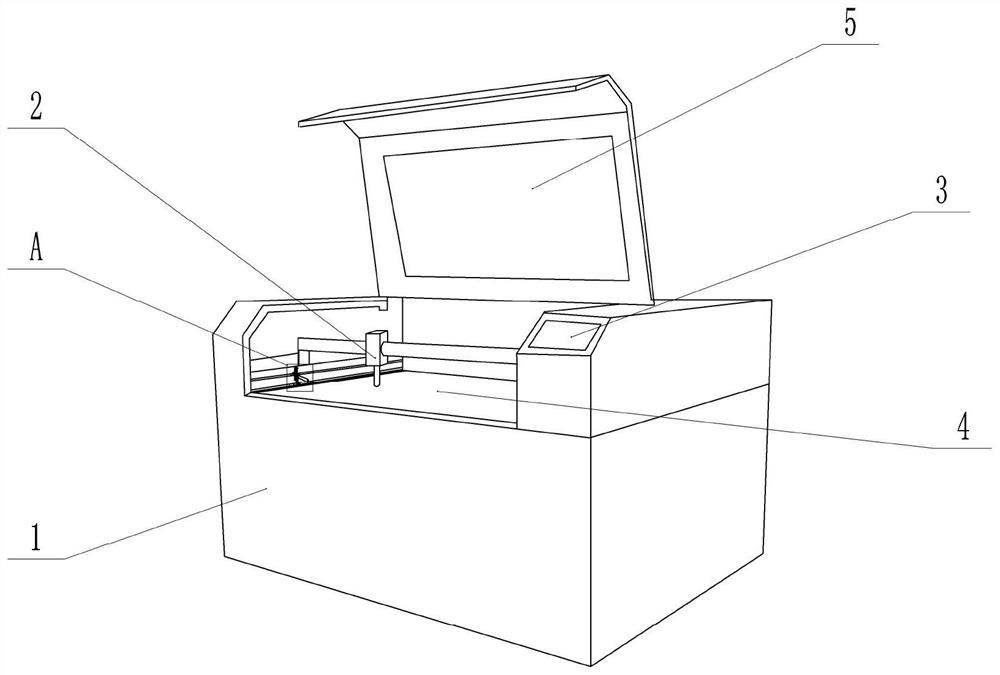

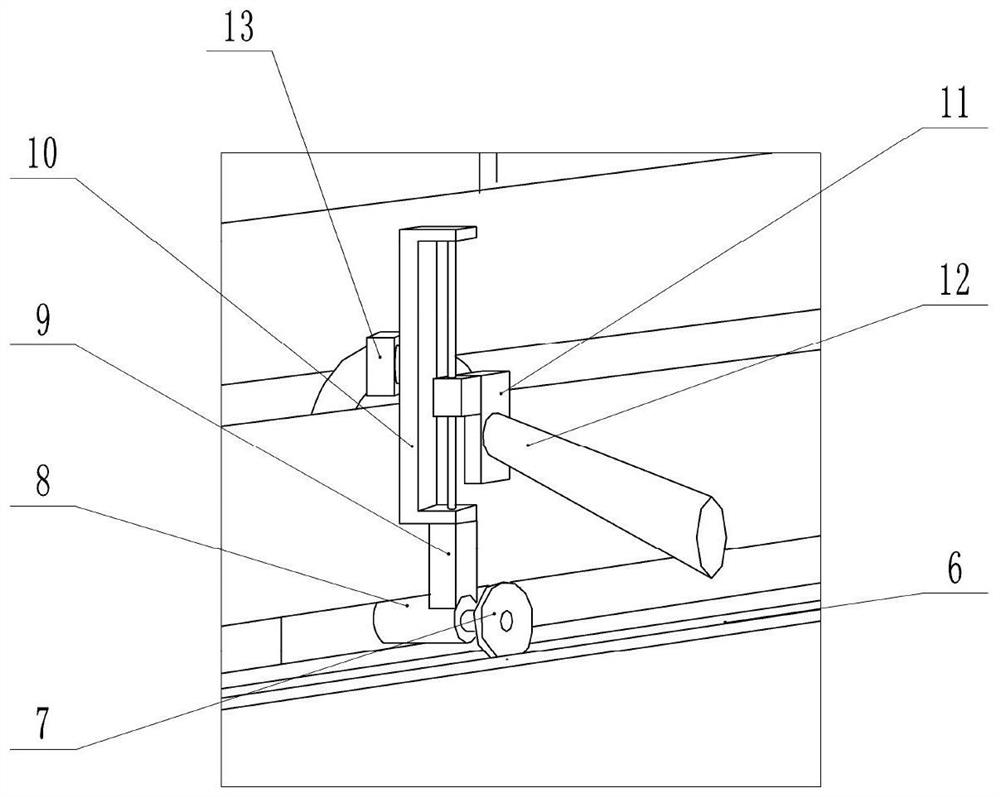

[0030] such as Figure 2 Compared with the first embodiment, the only difference is that it also includes a dust cleaning subsystem. The cross-platform motion control system of the laser engraving machine of the invention is mainly used for processing non-metallic air inlet pipes (hereinafter referred to as air inlet pipes for short), that is, for cutting connecting holes on the non-metallic air inlet pipes. In actual use, a relatively sealed working chamber is formed after the outer cover 5 is covered, and a large amount of smoke and dust will be generated during cutting in the working chamber. Aiming at this part of smoke and dust, the commonly used method is to set an exhaust device at the side of the working chamber, and remove the smoke and dust escaping in the working chamber directly by negative pressure suction. However, since the air inlet pipe is processed, the actual working process is as follows: open the outer cover 5, fix the air inlet pipe on the plane table 4 by cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com