A circulating fluidized bed degasser for preparing hydrogen fluoride

A technology of circulating fluidized bed and degassing device, applied in the directions of hydrogen fluoride, fluorine/hydrogen fluoride, etc., can solve the problems of gas-film mass transfer coefficient of specific surface area, gas-phase flow pressure drop, short liquid residence time, large gas-phase pressure drop, etc. , to achieve the effect of improving thermodynamic efficiency, large liquid film mass transfer coefficient, and small liquid backmixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the drawings and specific embodiments.

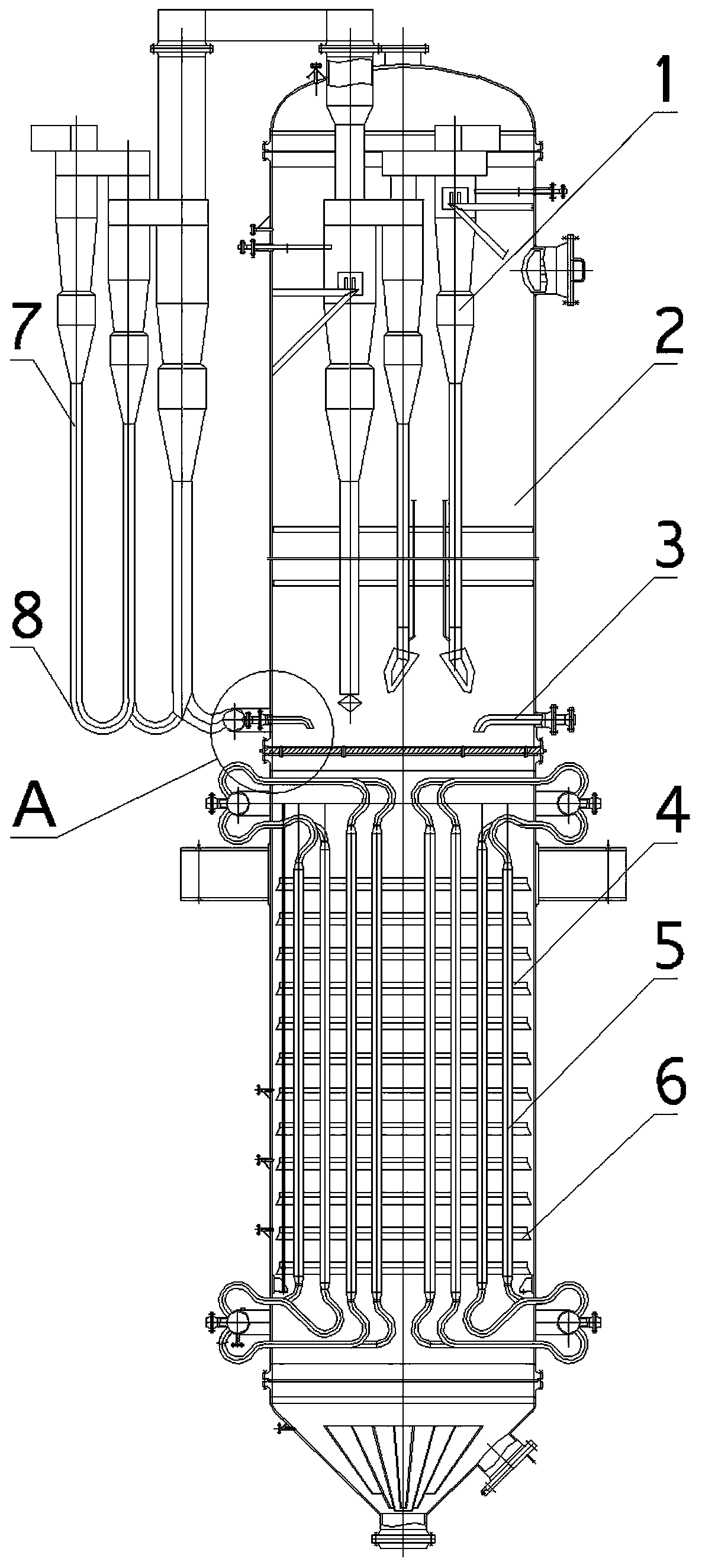

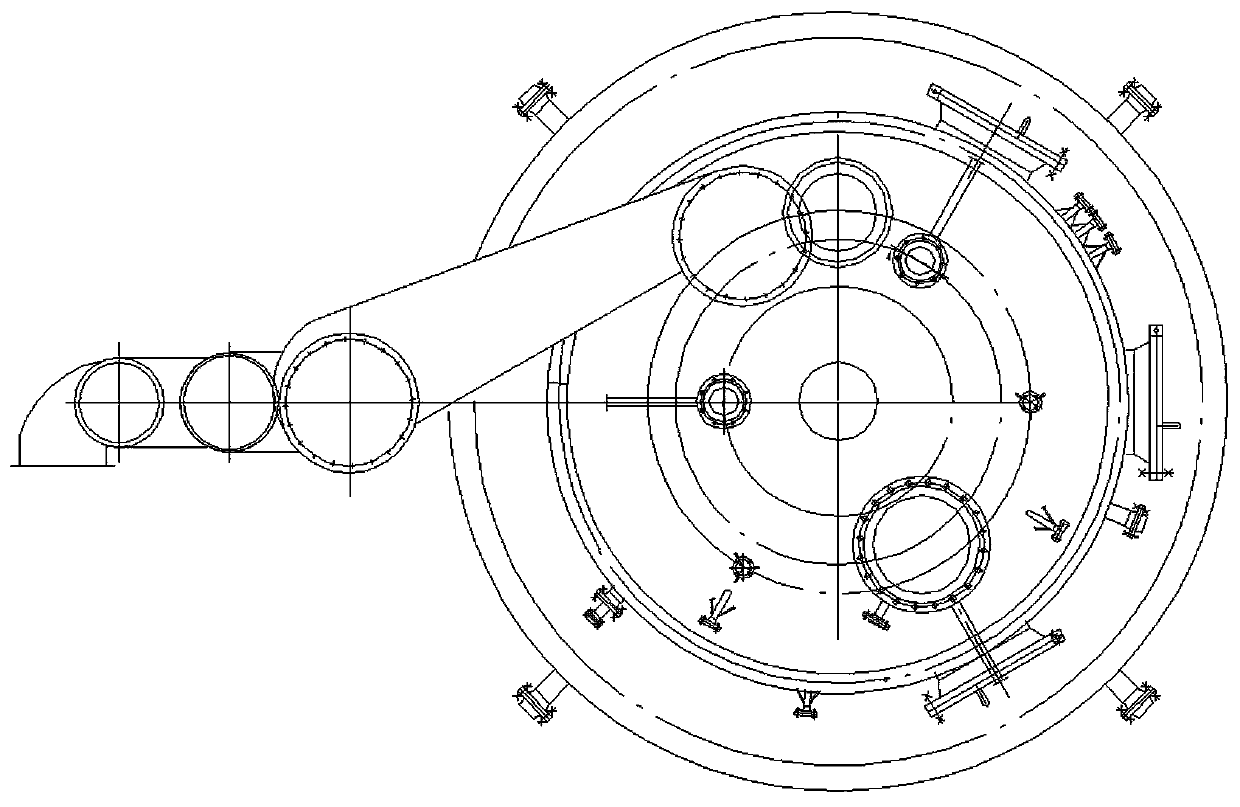

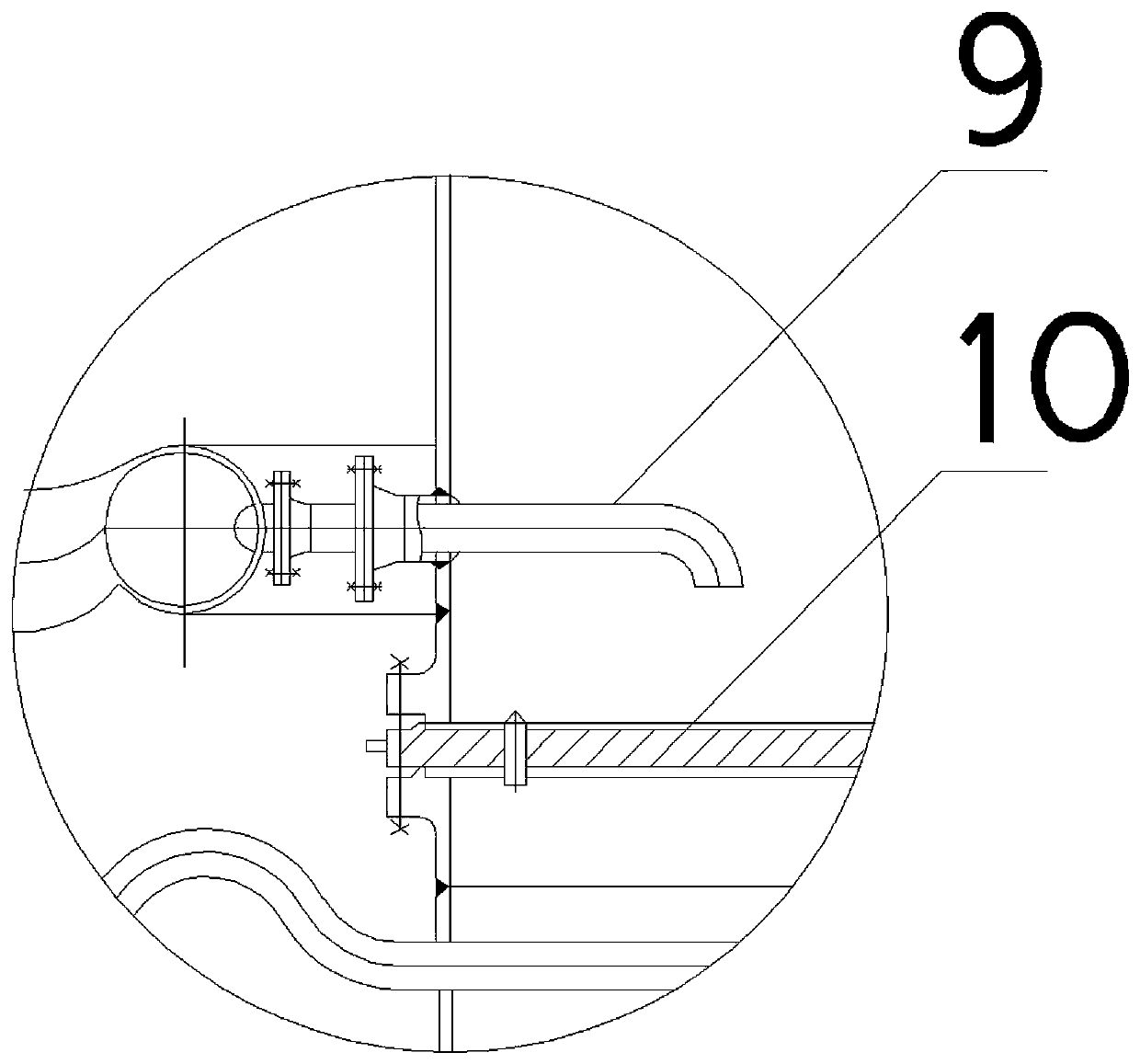

[0022] Such as figure 1 , figure 2 , image 3 As shown, a circulating fluidized bed degassing device for preparing hydrogen fluoride is characterized in that it includes a multi-stage cyclone separator condenser I1, a circulating fluidized bed degassing tower body 2, a material liquid connection pipe 3, a thermostat 4, a multi-stage cyclone Separating condenser Ⅱ7, U-shaped liquid sealer 8, return material 9, and liquid receiving tray 10.

[0023] The circulating fluidized bed degassing tower body 2 is divided into two upper and lower sections, the upper part is a rectification section, and the lower part is a stripping section. The rectification section is designed with a multi-stage cyclone separation condenser I1 and a multi-stage cyclone separation condenser II7. The stripping section is designed with a thermostat 4, and the crude hydrofluoric acid liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com