Method for preparing activated carbon by taking coconut shells as raw materials

A technology for preparing activated carbon and coconut shells, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as insufficient activated carbon performance, and achieve the effect of good adsorption performance and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

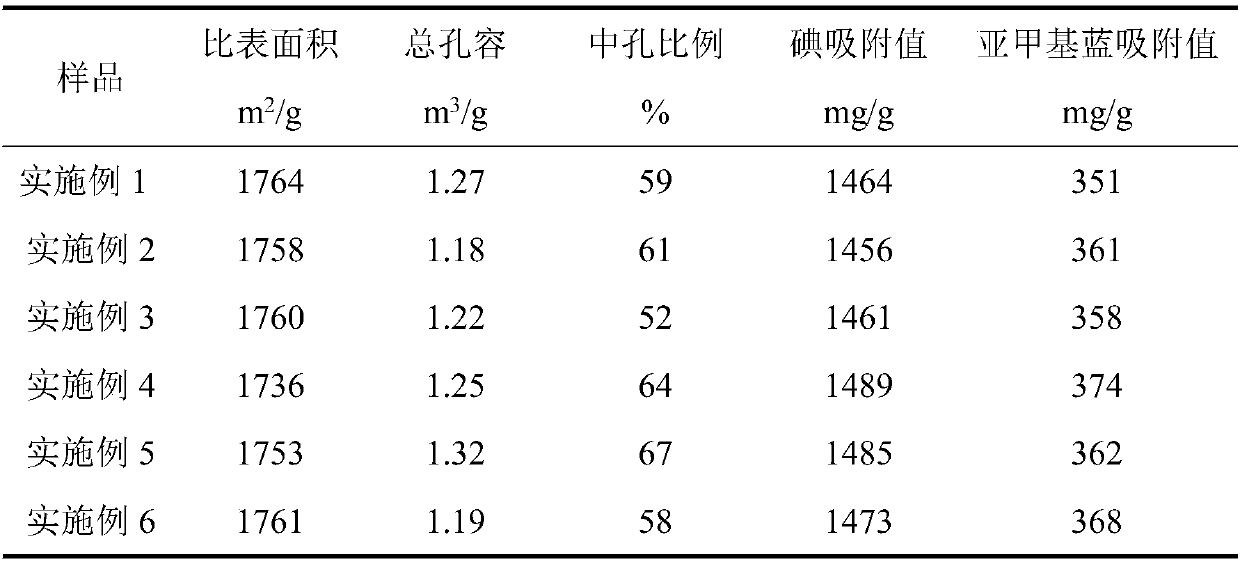

Examples

Embodiment 1

[0039] In the present embodiment, the method for preparing gac from coconut shell comprises the steps:

[0040] S1, the mixing of raw materials: choose coconut shell, pulverize, obtain coconut shell powder; Dry described coconut shell powder to water content rate 18%; Select concentration to be the thermal food grade phosphoric acid of 64%-, according to coconut shell powder: Thermal food-grade phosphoric acid = 1:1.5 for mixing, kneading and stirring evenly, and static soaking for 40 minutes to obtain a mixed material;

[0041] S2. High-temperature carbonization: take the mixed material obtained in step S1 and place it in a muffle furnace for carbonization treatment to obtain a carbonized material; wherein, the carbonization temperature is 270° C., and the carbonization time is 40 minutes;

[0042] S3. Activation: take the carbonized material obtained in step S2, and activate it to obtain the activated material; wherein, the activation temperature is 510° C., and the activati...

Embodiment 2

[0050] In the present embodiment, the method for preparing gac from coconut shell comprises the steps:

[0051]S1, the mixing of raw materials: select coconut shell, pulverize, obtain coconut shell powder; Dry described coconut shell powder to moisture content 24%; Select the thermal method food-grade phosphoric acid that concentration is 78% for use, according to coconut shell powder: heat French food-grade phosphoric acid = 1:1.9 ratio for mixing, kneading and stirring evenly and static soaking for 55min to obtain the mixed material;

[0052] S2. High-temperature carbonization: take the mixed material obtained in step S1 and place it in a muffle furnace for carbonization treatment to obtain a carbonized material; wherein, the carbonization temperature is 335° C., and the carbonization time is 55 minutes;

[0053] S3. Activation: take the carbonized material obtained in step S2, and activate it to obtain the activated material; wherein, the activation temperature is 560° C., ...

Embodiment 3

[0061] In the present embodiment, the method for preparing gac from coconut shell comprises the steps:

[0062] S1, the mixing of raw materials: select coconut shell, pulverize, obtain coconut shell powder; Dry described coconut shell powder to water content rate 21%; Select the thermal method food grade phosphoric acid that concentration is 70% for use, according to coconut shell powder: heat French food-grade phosphoric acid = 1:1.7 ratio for mixing, kneading and stirring evenly and static soaking for 48min to obtain the mixed material;

[0063] S2. High-temperature carbonization: the mixed material obtained in step S1 is placed in a muffle furnace for carbonization treatment to obtain a carbonized material; wherein, the carbonization temperature is 300° C., and the carbonization time is 50 minutes;

[0064] S3. Activation: take the carbonized material obtained in step S2, and activate it to obtain the activated material; wherein, the activation temperature is 530° C., and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com