Regenerated active powder prepared from construction waste as well as method and device thereof

A construction waste and active powder technology, applied in the field of construction waste recycling, can solve the problems of harmful human health, infiltration of harmful substances, low compressive strength, etc., and achieve the effect of increasing value and improving activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

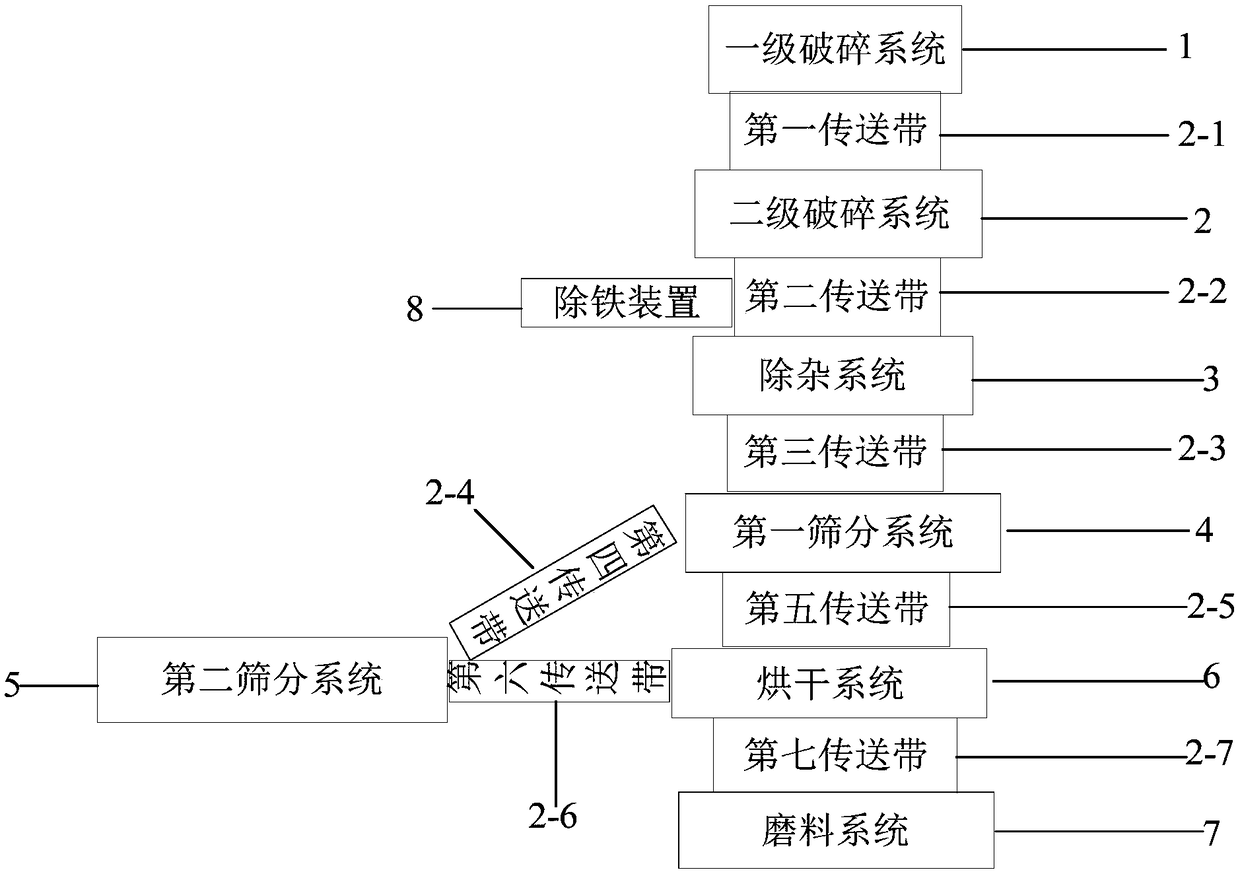

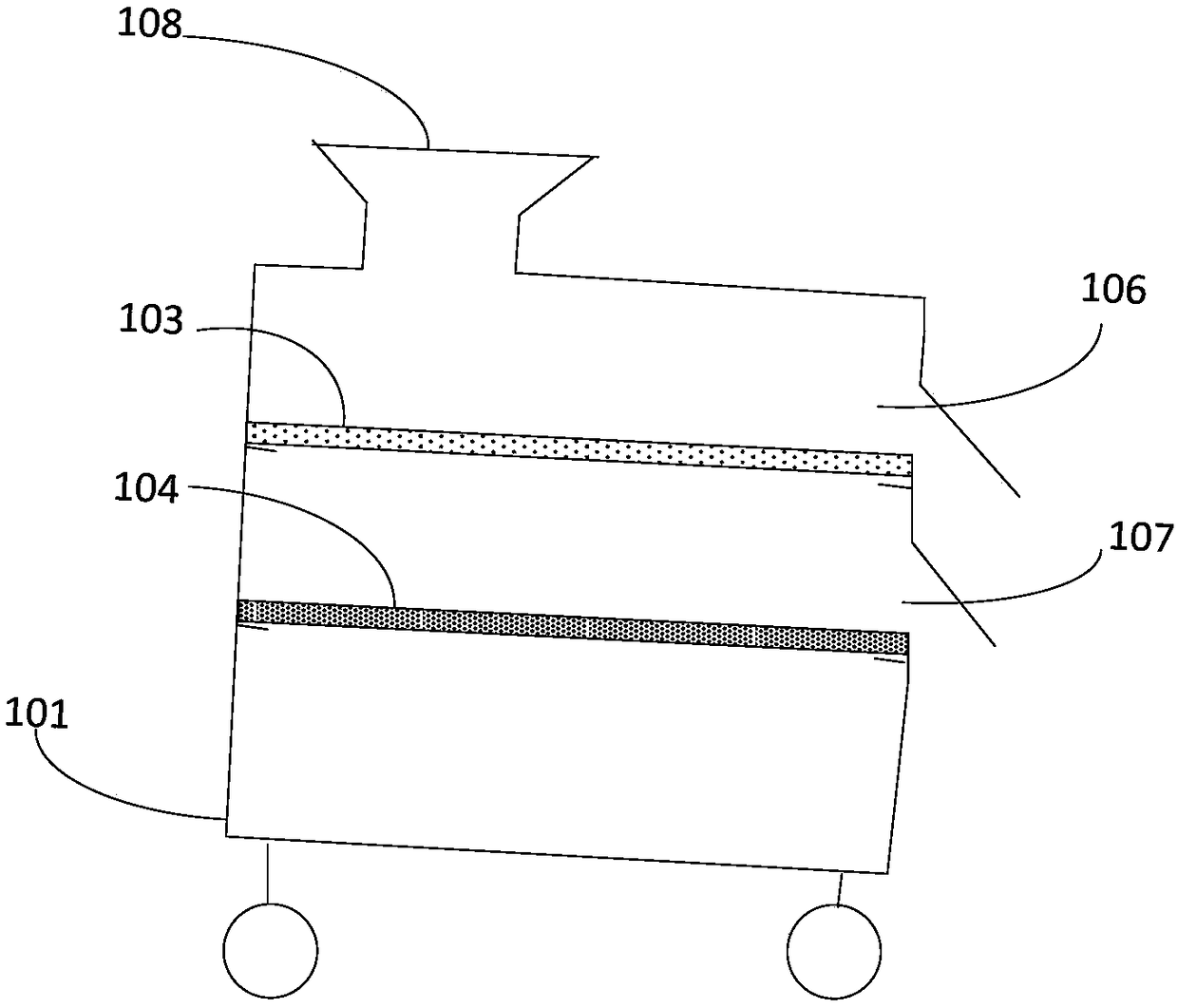

[0048] The construction waste from the demolition of steel-concrete residential buildings is conveyed to the jaw crusher for primary crushing through the feeder, and then the steel bars are manually stripped and removed, and the materials after primary crushing are conveyed to the impact crusher through the first conveyor belt for secondary crushing. Crushed to obtain crushed materials with a particle size of no more than 50mm; the obtained crushed materials are transported to the air separation and impurity removal machine through the second conveyor belt, and light impurities such as plastics, wood chips and cloth pieces are removed by the air separation impurity removal machine, and the second conveyor belt There is a permanent magnet connected in the air. When the crushed material is transported to the winnowing machine through the second conveyor belt, the ferromagnetic substance in the crushed material is absorbed by the permanent magnet, and the impurity-removed material ...

Embodiment 2

[0050] The construction waste from the demolition of steel-concrete residential buildings is conveyed to the jaw crusher for primary crushing through the feeder, and then the steel bars are manually stripped and removed, and the materials after primary crushing are conveyed to the impact crusher through the first conveyor belt for secondary crushing. Crushed to obtain crushed materials with a particle size of no more than 50mm; the obtained crushed materials are transported to the air separation and impurity removal machine through the second conveyor belt, and light impurities such as plastics, wood chips and cloth pieces are removed by the air separation impurity removal machine, and the second conveyor belt There is a permanent magnet connected in the air. When the crushed material is transported to the winnowing machine through the second conveyor belt, the ferromagnetic substance in the crushed material is absorbed by the permanent magnet, and the impurity-removed material ...

Embodiment 3

[0052] The construction waste from the demolition of steel-concrete residential buildings is conveyed to the jaw crusher for primary crushing through the feeder, and then the steel bars are manually stripped and removed, and the materials after primary crushing are conveyed to the impact crusher through the first conveyor belt for secondary crushing. Crushed to obtain crushed materials with a particle size of no more than 50mm; the obtained crushed materials are transported to the air separation and impurity removal machine through the second conveyor belt, and light impurities such as plastics, wood chips and cloth pieces are removed by the air separation impurity removal machine, and the second conveyor belt There is a permanent magnet connected in the air. When the crushed material is transported to the winnowing machine through the second conveyor belt, the ferromagnetic substance in the crushed material is absorbed by the permanent magnet, and the impurity-removed material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com